Rebar Tying Machine ties the 2 combined rebars from 6-68mm

- Payment Type:

- T/T, Western Union, Cash

- Min. Order:

- 50 Piece/Pieces

- Min. Order:

- 50 Piece/Pieces

- Delivery Time:

- 5 Days

- Transportation:

- Ocean, Air, internation express

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50000 |

| Supply Ability: | 50 |

| Payment Type: | T/T,Western Union,Cash |

| Certificate: | CE&RoHS |

| Transportation: | Ocean,Air,internation express |

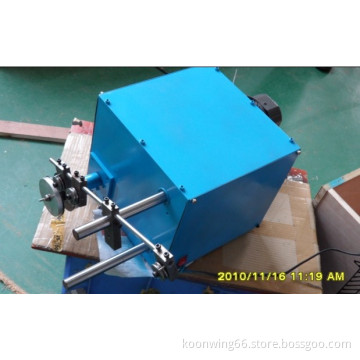

W-0041 used in wire diameter of 1.5MM, each bar is only a knot around the wire can be tied in diameter 8-68MM range of steel, the machine can be reinforced in accordance with intelligent control of the thickness of the wire length. 3300MAH Ni-use hydrogen batteries, is essential for site workers in the hands or arms. is the site owner of the new cost-effective choice.

KW-0041 automatic rebar tying machine reinforced the main performance parameters are as follows: whole weight of 3.3KG. Largest diameter Banding 68MM, motor voltage 9.6V. Make a knot, tied for about 1.2 seconds, the length of the basis of banding wire with the size of the reinforcement. (such as banding 10MM * 10MM 2 reinforced only wire 120MM.) A rechargeable battery can play more than 600 head node. The use of environment-friendly high-capacity (3300MAH) Ni-MH battery, charging time is about 70 minutes.the wirebundle diameter of 1.5MM, each 28 meters long wire roll.

KW-0041 machine distinguishing features: 1. Banding range: diameter small to be banded Φ8.0MM; large Φ68MM, wide adaptation occasions. 2. Tied up big:wire used for Φ1.5MM, increased the tensile strength of binding nodes; the node requirements of the tensile strength depends largely on the thickness wire. 3. Consumption of less wire: aircraft as a result of a "pull back" feature, saving a great extent tied to node wire consumption, lower consumption costs, the required length of wire to 110 MM for MM. Process more or less as follows: To the maximum length will be sent wire clamping ----- -----wire front-end pull back to the machine to be shut up tightly fitting steel banding wire ---- cut the tail and twist tight wire -- ---- back to digital. the whole process takes about 1.2 seconds

Package of products include a tool box, a console, two batteries, a charger, four volumes of the wire, a pliers, a wrench inside the six-foot, brochures, product cutaway view, the product of the operation of a CD-ROM.

Each machine with a tool for external color box Packing Size: 456 * 380 * 145MM weight 9.3KG.

Related Keywords