liquid silicone rubber for food grade mold making

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| MOQ | 200kg |

|---|---|

| materials | liquid silicone |

| model | E642 |

| place | China |

| quality | like dow-corning |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

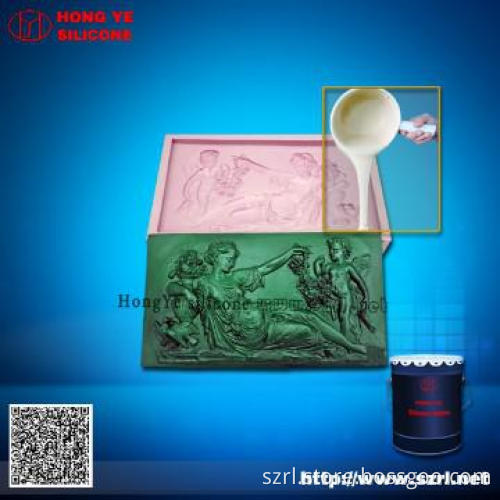

liquid silicone rubber for food grade mold making

Delivery Time: within 3 days after payment confirmed in our bank.

Payment Terms: L/C,T/T

liquid silicone rubber for food grade mold making:

liquid silicone rubber for food grade mold making is generally named two-components silicone rubber, Part A and part B.

It features an exceptional fluidity and good operability. The mixing ratio is 1:1,mainly be suitable for making molds application.

liquid silicone rubber for food grade mold making Applications:

liquid silicone rubber for food grade mold making could be mainly used for making concrete stones, wax molds, PU molds, resin molds, gypsum casting, candle molding and chocolate , candy and any other FDA food product mold making,prototyping etc.

Instruction of liquid silicone rubber(10:1) for food grade mould making

liquid silicone rubber for food grade mold making are generally named as two-part room temperature sulfurated silicone rubber, which features an exceptional fluidity and good operability. When mixed with 2-3% curing agent, they can still be operated within 30 minutes, but will be formed after 2-3 hours. With resistance to deformation, high temperature, acid and alkali, and expansion, silicon flexible molds are used for mold duplication and delicate mold making for poli crafts, resin crafts lighting and candle crafts.

Features of liquid silicone rubber(10:1) for food grade mould making

(1)high tensile & tear strength

(2) Low linear shrinkage

(3)free Curing agent

(4)brushing & pouring

(5) high duplication times

Technique Data Sheet of HY-E series liquid silicone rubber for food grade mold making :

Product |

E-620 |

E-625 |

E-630 |

E-642 |

Appearance |

Translucent |

Translucent |

Translucent |

Translucent |

Hardness(shore A) |

20±2 |

25±2 |

30±2 |

42±2 |

Mix ratio(A:B) |

1:1/10:1 |

1:1/10:1 |

1:1/10:1 |

1:1/10:1 |

Viscocity Part A(mPa.s) |

23000±2000 |

27000±2000 |

25000±2000 |

30000±2000 |

Viscocity Part B(mPa.s) |

3500±500 |

3500±500 |

2400±500 |

6000±500 |

Tensile strength (kgf/cm2) |

45±5 |

48±5 |

50±5 |

65±5 |

Tear-strength (kN/m) |

20±2 |

22±2 |

18±2 |

16±2 |

Elongation(%) |

500±50 |

500±50 |

450±50 |

450±50 |

Pot life/working time (mins) |

30-40 |

30-40 |

30-40 |

30-40 |

Curing time/setting time (hrs) |

3-4hrs(25°C) 110-20mins(60°C) |

3-4hrs(25°C) 110-20mins(60°C) |

3-4hrs(25°C) 110-20mins(60°C) |

3-4hrs(25°C) 1 110-20mins(60°C) |

Shrinkage rate (%) |

0.1 |

0.1 |

0.1 |

0.1 |

(Note: Other hardness is adjustable)

Package of liquid silicone rubber(10:1) for food grade mould making

Need any help on silicone rubber, please feel free to contact Ms Crystal:

Tel:86-755-89212369

Mob:86-18938867509

E-mail: hyxd(at)szrl(dot)net

Skype:shisi1991

You can also send me e-mail by scanning 2 Dimensional Bar Code below:

Additional Information

| Payment Terms | L/C, T/T, Western Union |

|---|---|

| Minimum Order | 200kg |

| Lead Time / Delivery Time | 29 Day(s) |

| Sample Available | YES |

| Delivery Details | Packaging & Delivery Packaging Detail: 25kg/drum and 200kg/drum Delivery Detail: within 3 days after getting payment |

| FOB Port | Shenzhen |

| Loading Info | Packaging & Delivery Packaging Detail: 25kg/drum and 200kg/drum Delivery Detail: within 3 days after getting payment |

| Packing Info | Packaging & Delivery Packaging Detail: 25kg/drum and 200kg/drum Delivery Detail: within 3 days after getting payment |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords