2014 new silicone liquid rubber molds for gypsum cornice molding

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| Cetification | ISO9001:2000,SGS,RoHS |

|---|---|

| catalyst | FOC |

| validity | 1 year |

| state | liquid two parts |

| feature | two part silicone,liquid |

| Eco-Friendly | Yes |

| Test Report | SGS |

Detail Description

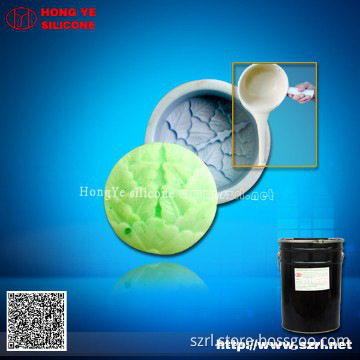

2014 new silicone liquid rubber molds for gypsum cornice molding

Features of molds for gypsum cornice molding

silicone liquid rubber molds for gypsum cornice molding flowing liquid with general hardness of 22-50A° after curing with features:

1. Resistance to deformation and high-temperature, acid-alkali and expansion

2. Good tensile strength, tear strength and elongation

3. High reproduction times

Applications of silicone liquid rubber molds for gypsum cornice molding

Mould making silicon rubber is suitable for industries such as toys, gifts, decoration, plate engrave, human replica, art crafts,

resin crafts, poly resin crafts, unsaturated resin crafts, candle crafts, plastic crafts, stationeries, plaster crafts and Buddhist

statue crafts

Datasheet of 2014 new silicone liquid rubber molds for gypsum cornice molding

Model |

Appearance |

Viscosity (cs) |

Hardness (Ao) |

Tensile Strength (kgf/c) |

Tear Strength (kgf/) |

Elongation (%) |

Mixing ratio(%) |

Operating Time(H) |

Curing Time(H) |

625 |

White |

14000~16000 |

25~28 |

≥35 |

≥25 |

≥500 |

2~3 |

0.5 |

2~4 |

Package and storage of liquid silicone rubber for GRC molds making

1. 20kg or 200kg /drum.

2. It is a kind of non-dangerous goods, and it should be stored at a cool and dry place, please keep it from sun and rain.

Why could the silicone mold be reused only for a few times?

It can be due to the following reasons:

a. Adding too much silicone oil in to silicon rubber. Silicon oil is an additive which destroies the molecular weight of

silicone rubber and reduce the tension and tear strength.

b. Using the silicon rubber with a high hardness to make molds for small sized products with delicate and intricate

designs and the silicon rubber with a low hardness to makes molds for large sized products with simple designs.

(Notes: we should choose the silicon rubber specifically according to the requirements of our products to avoid this

problem.)

and casting supplies serve as the raw material for casting molds, which can form cured silicone elastomer characterized by the resistance to chemicals, deformation, extreme temperature, acid & alkali and expansion. RTV-2 silicone rubber is mainly applicable for model making molds, resin mold(unsaturated, poly), sculpture mold, plaster & gypsum mold, architectural decoration mold, prototyping and molds for candle, art crafts, stationery, tyre, GRC product, plastic product, shoe soles, etc.

Additional Information

| Payment Terms | L/C, T/T, Western Union |

|---|---|

| Minimum Order | 200KG |

| Lead Time / Delivery Time | 5 Day(s) |

| Sample Available | YES |

| Delivery Details | within 3 days after payment confirmed in our bank |

| FOB Port | Shenzhen |

| Loading Info | by sea or by air |

| Packing Info | 25kg/drum and 25kg/drum |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords