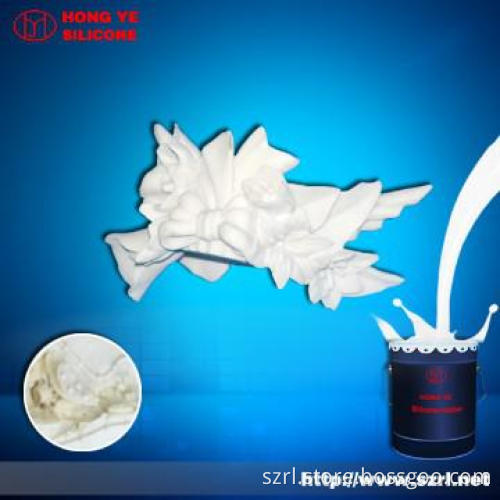

liquid silicone for making molds in casting

Your message must be between 20 to 2000 characters

Contact NowBasic Specification

| Payment Terms: | TT100% |

|---|---|

| application | liquid silicone for making molds in casting |

| color | any |

| MOQ | 200Kg |

| Port: | shenzhen |

| Product Material | Rubber |

| Shaping Mode | Silicone Mould |

Detail Description

liquid silicone for making molds in casting

liquid silicone for making molds in casting application:

room temperature silicone rubber for making molds is suitable for product duplication and molds manufacture such as

1) toys, gifts

2) decoration, plate engrave

3) human replica, art crafts,

4) resin crafts, unsaturated resin crafts

5) poly resin crafts, candle crafts, plastic crafts

6) stationeries, plaster crafts, Buddhist statue crafts, etc.

liquid silicone for making molds in casting features:

a. good characteristics of easy-operation

b.light viscosity and good flowability

c. favorable tension

d. low shrinkage

e. no deformation

f. high temperaure resistance, acid and alkali-resistance and ageing resistance

Advantage of liquid silicone for making molds in casting:

Molding silicone rubber has advantage of excelenlt fluidity and good operational performance, an elastic silicone rubber mold will be obtained with resistance to deformation, high-temperature, acid and alkali and expansion, comfortable duplication times and free sample avalibale.

liquid silicone for making molds in casting specifications:

HY625# liquid silicone for making molds in casting

HY630# liquid silicone for making molds in casting

HY620# liquid silicone for making molds in casting

HY628# liquid silicone for making molds in casting

HY638# liquid silicone for making molds in casting

HY640# liquid silicone for making molds in casting

liquid silicone for making molds in casting operations:

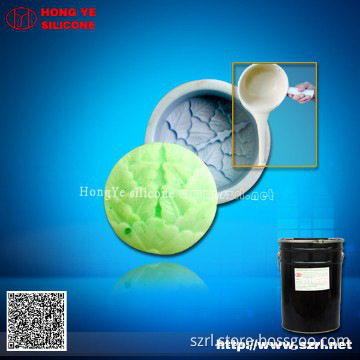

Molding silicone rubber is a kind of flowing liquid, and it consists of two component, part A is a flowable liquid silicone rubber, part B is the curing agent.

Firstly, after your previous work of dealing with the original model, take some liquid silicone rubber, add 2%~3% cuing agent of the amount of silicon and mix them evenly.

Then after vacuum-pumping the mixture, you can pour it into the mold frame. The silicone mold will cured in 2~3 hours.

Notes of liquid silicone for making molds in casting:

The time for vacuum-pumping should be less than 3-5mins, otherwise, once the silicone rubber has cross-link reaction during vacuumizing, it will not be operated.

liquid silicone for making molds in casting with FOQ:

Why does the mold made of silicone rubber have an unsmooth surface with tracks and strips on it?

It is due to product or model to be molded should hasn\'t been sanded or polished . If the mold or product is not sanded or polished, the mold made of whatever quality silicone rubber will not be good and smooth enough since the mold or the product itself is not smooth or perfect. Another case is that uneven brushing of the release agent will also bring about unsmoothness of the mold.

Welcome to visit www(dot)szrl(dot)com and call for any time

Additional Information

| Payment Terms | L/C, T/T, Western Union |

|---|---|

| Minimum Order | 200KG |

| Lead Time / Delivery Time | 10 Day(s) |

| Sample Available | YES |

| Delivery Details | within 3 days after payment confirmed in our bank |

| FOB Port | Shenzhen |

| Loading Info | by ship or air |

| Packing Info | 25kg/drum and 200kg/drum |

| Target Market(s) | North America, Oceania, Southeast Asia, Eastern Europe, Africa(except Middle East), Hong Kong/ Macao/ Taiwan, Latin America, Japan & Korea, Middle East & South Asia, Mainland China, Western & Southern Europe, Northern Europe, Central & Southern Asia, Middle East |

Related Keywords