RTV-2 Silicone Rubber For Pad Printing

- Payment Type:

- L/C, T/T, Paypal, Western Union

- Incoterm:

- FOB

- Min. Order:

- 200 Kilogram

- Min. Order:

- 200 Kilogram

- Delivery Time:

- 3 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen China |

|---|---|

| Productivity: | 8 tons |

| Supply Ability: | 8 tons a day |

| Payment Type: | L/C,T/T,Paypal,Western Union |

| Incoterm: | FOB |

| Certificate: | ISO 9000/9001/9004/19011: 2000 Others |

We are a well-reputed firm that manufacture, export, trade and supply an extensive range of RTV-2 Silicone Rubber For Pad Printing in Longgang, Guangdong, China.

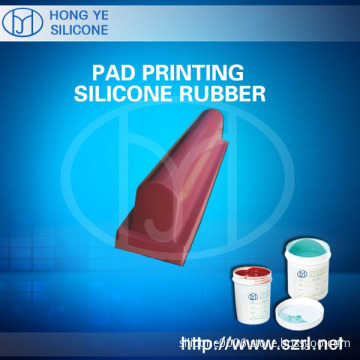

Pad printing silicone rubber is mainly use for printing irregular patterns of plastic toys, electroplating toys and trade makers . Pad printing silicone rubber as a carrier which transfer patterns on the steel plate to the toys products surface.

a. resistance to deformation, high-temperature

b. high printing times

c. good aging resistance

d. exceptional elasticity

e. great printing effect

HY-918 is a kind of silicone rubber to make the printing pads for plastic toys, craft works, product printing.rnHY-918 with the advantages of high temperature resistance, abrasion resistance, good printing effect, etc., which made of top-quality raw material, is processed through high-temperature machining. The product is mainly applicable to plastics toys, electroplating products, electronic toys, trademarks and irregular pattern printing. The silicon pad is a carrier which transfer printing the patterns on the steel plate onto the toy products' surface. Features of liquid pad printing silicone rubberrna. Resistance to deformation, high-temperaturernb. High printing timesrnc. Good aging resistancernd. Exceptional elasticityrne. Great printing effect

FAQ of liquid pad printing silicone rubber

Why the silicon pad is non-durable?

This problem is caused not by the liquid silicon rubber itself, but in the process of filtering, the filtering handled not properly and impurities are not all filtered out; or in the process of packing as containers not cleaned thoroughly.

As the silicon oil will break the molecular chain of the silicon rubber. More silicon oil added, softer the pad printing will be, meanwhile nondurable and easy ageing it will also turn to be.

Some customers do not know well about the performance of silicon rubber. Actually, the durability of printing pad is closely related to the size of printing pattern. Some factories do not want to take the trouble to change the printing pad. While in fact, for large pattern, large silicone pads should be used, otherwise, use small one.(Generally, the ratio of the silicone pad to printing pattern is 3:1)

Related Keywords