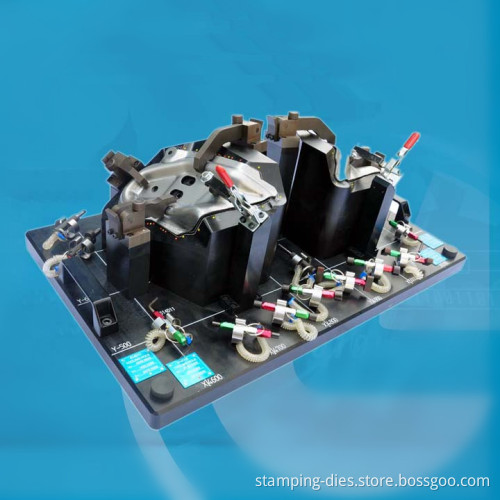

Checking Fixture

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

GLS is a professional punching mold manufacturer in metal stamping tools & dies (type: Plate /casting) for auto parts, home (household) appliances and consumer electronics...

Die Type: Progressive die, transfer die, stage die

Phone: +861827-815876, Tina Wu

Dies Procedure:

PO -- Product Analysis -- Mould Design -- Customer Approval -- Purchase Materials -- Offers CNC Machining -- Heat Treatment -- Grinding -- Wire EDM -- Die Assembly -- Die Try -- Sample Approval -- Mould Shipment

1. R&D: We support customer R&D. Make the files or improve the design if you needed.

2. Negotiation: The quality, price, material, delivery time, payment item, ect.

3. Place an order: According your own design or you choose our design.

4. Mould Deign: According customers' request to build the mould. Before make the mould, we send mould design to customer approval first; Before move forward to production; We send samples to customer to confirm first.

5. Sample shoot: If the first sample come out is not satisfied customer, we modify the mould and until meet customers satisfactory.

6. Delivery: Delivery goods by sea or by air, according customers requirement.

Kindly Check below our equipment list:

Die Type: Progressive die, transfer die, stage die

Phone: +861827-815876, Tina Wu

Dies Procedure:

PO -- Product Analysis -- Mould Design -- Customer Approval -- Purchase Materials -- Offers CNC Machining -- Heat Treatment -- Grinding -- Wire EDM -- Die Assembly -- Die Try -- Sample Approval -- Mould Shipment

1. R&D: We support customer R&D. Make the files or improve the design if you needed.

2. Negotiation: The quality, price, material, delivery time, payment item, ect.

3. Place an order: According your own design or you choose our design.

4. Mould Deign: According customers' request to build the mould. Before make the mould, we send mould design to customer approval first; Before move forward to production; We send samples to customer to confirm first.

5. Sample shoot: If the first sample come out is not satisfied customer, we modify the mould and until meet customers satisfactory.

6. Delivery: Delivery goods by sea or by air, according customers requirement.

Kindly Check below our equipment list:

| Equipments | ||

| Name | Specification | Quantity |

| Machining Equipments | ||

| Surface Grinding Machine | 600*300 | 1 set |

| Surface Grinding Machine | 1000*600 | 2 sets |

| Surface Grinding Machine | 1600*600 | 1 set |

| Vertical Drilling Machine | *1-32 | 3 sets |

| Milling machine | 3# | 6 sets |

| Radial Drilling Machine | *1-32 | 5 sets |

| Manual Gringding Machine | 350*150 | 6 sets |

| Numerical Control Equipments | ||

| EDM Precision Wire Cutting Machine | 900*600 | 1 set |

| EDM Precision Wire Cutting Machine | 700*400 | 1 set |

| EDM Precision Wire Cutting Machine | 600*400 | 3 sets |

| EDM Precision Wire Cutting Machine | 500*300 | 1 set |

| EDM Precision Wire Cutting Machine | 300*200 | 1 set |

| EDM Wire Cutting Machine | 800*600 | 3 sets |

| EDM Wire Cutting Machine | 630*500 | 2 sets |

| EDM Wire Cutting Machine | 320*250 | 4 sets |

| CNC Machine | 3000*1600*750 | 1 set |

| CNC Machine | 2100*1000*700 | 1 set |

| CNC Machine | 2000*1300*1000 | 1 set |

| CNC Machine | 2000*1300*700 | 1 set |

| CNC Machine | 1300*700*700 | 1 set |

| CNC Machine | 1200*760*600 | 1 set |

| CNC Machine | 1000*660*500 | 2 sets |

| CNC Machine | 650*500*450 | 4 sets |

| Tryout Equipments | ||

| Press Machine | 800T (4000*1800*1000) | 1 set |

| Press Machine | 300T (2300*900*700) | 1 set |

| Press Machine | 250T (1200*800*700) | 1 set |

| Press Machine | 110T (1600*900*480) | 1 set |

| Hydraulic Machine | 400T(1600*900) | 1 set |

| Measuring Equipments | ||

| 3D CMM | 1000*800*600 | 1 set |

| 3D CMM | 800*600*500 | 1 set |

| OHP | 150*50 | 1 set |

| Height Gauge | 0-600 | 1 set |

| Glossy Plug Gauge | 2.00-6.00 | 7 sets |

| Gauge Block | 1.0-100 | 2 sets |

Related Keywords

Related Keywords