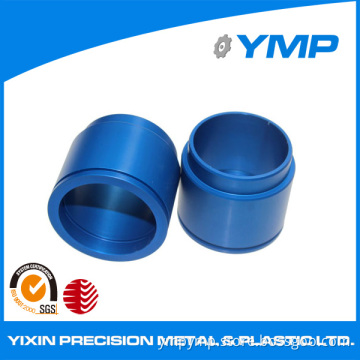

High Precision Metal Machining CNC Turning Spare Part

- Payment Type:

- T/T, Paypal, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Payment Type: | T/T, Paypal, Western Union |

Product Description

Product Description

cnc turning spare part:

1. Part Description:

Metal machining parts:

Material:Aluminum

Surface Treatment:Anodize and sandblasting

Process: Turning

MOQ: 1-10 PCS

Delivery time: 7-20days

2. Our Service:We are professional in NC & CNC machining service and molding service for OEM and ODM parts. Types include turning, milling, grinding, stamping, bending, welding, die casting, drilling, tapping and plastic injection.

3.Our Factory:The machines are come from Taiwan,Japan as well as Germany.High precision and quality part is our always target,the tolerance we can reach +/-0.01mm(for meta part),+/-0.03mm for plastic part.

4.Product Inspection:

Every part will be inspected during the machining and we will offer you the QC report before arrange shipping,Sure that all parts you recieved will meet your request.

5.ISO9001 2008 quality certificate approval:

High quality and best service is our habit,we have the specification machining and inspection process,do believed that our product will satisfied you.

6. Parts Information:

(1). Applicable Material---Aluminum/zinc alloy, iron, steel alloy, plastic, brass, steel, and stainless steel

(2). Surface treatment---polishing, zinc plating, nickel plating, chrome plating, anodizing.

(3). Drawing format---IGS, SLD 2012, X_T, STEP, CAD 2012 and PDF

(4). Tolerance: Plastic part can reach +/-0.03mm, metal part can reach +/-0.01mm

(5). Payment Terms: L/C, T/T, Paypal&Western Union is acceptable.

(6). Packagings: Standard package/ Pallet or container/As per customized specifications.

(7). Shipment Terms: Express&air freight priority/sea freight/ As per customized specifications.

7. Our Advantages:

(1). Advance machine and the skillful workers

(2). Low MOQ (1-10PCS is even acceptable in some special conditions)

(3). Short lead time (7-30days according to order qty)

(4). Customized size and drawing is available

(5). Near shenzhen and HK, convenient transportation

(6). Have own the factory and the material price from wholesale

8. Currently market:

USA, Argentina, Canana, Australia, New Zealand, UK, France, HK, Singapore, Malaysia and so on...

We established strong relationships with our customers with unsurpassed customer support and a total commitment to quality and on time delivery. From the design phase to the parts and components being delivered to our customers, we take pride in the fact that we offer unprecedented integration and service to our customers.

9. FAQ:

(1). Question---Are you the trading company or factory?

Answer-----We have our own factory!

(2). Question---What`s the production capacity for your company?

Answer---Normally can reach 20, 0000 piecs annual.

(3). Question---How about the delivery time?

Answer---The delivery time will according to the part quantity, usually sample will need 7-10 days, and part production will need 25-30 days!

(4). Question---What`s the Scrap rate for the part?

Answer---The part we offer you will be 100% inspected by our quality department, so the parts we sent you will be qualified, it mean that the scrap rate is Zero

(5). Question---What we should do if we check out the part problem?

Answer---If you have recieved any unqualified part, you can take the pictures and sent to me, I will check it with our engineer. Then, we will redo them for free.

10.Contact us:

If you prefer to know more about us,email or call me,let` talk more!

Looking forward to establish the long term and friendly bussiness relationship with you and esteem company.

1. Part Description:

Metal machining parts:

Material:Aluminum

Surface Treatment:Anodize and sandblasting

Process: Turning

MOQ: 1-10 PCS

Delivery time: 7-20days

2. Our Service:We are professional in NC & CNC machining service and molding service for OEM and ODM parts. Types include turning, milling, grinding, stamping, bending, welding, die casting, drilling, tapping and plastic injection.

3.Our Factory:The machines are come from Taiwan,Japan as well as Germany.High precision and quality part is our always target,the tolerance we can reach +/-0.01mm(for meta part),+/-0.03mm for plastic part.

4.Product Inspection:

Every part will be inspected during the machining and we will offer you the QC report before arrange shipping,Sure that all parts you recieved will meet your request.

5.ISO9001 2008 quality certificate approval:

High quality and best service is our habit,we have the specification machining and inspection process,do believed that our product will satisfied you.

6. Parts Information:

(1). Applicable Material---Aluminum/zinc alloy, iron, steel alloy, plastic, brass, steel, and stainless steel

(2). Surface treatment---polishing, zinc plating, nickel plating, chrome plating, anodizing.

(3). Drawing format---IGS, SLD 2012, X_T, STEP, CAD 2012 and PDF

(4). Tolerance: Plastic part can reach +/-0.03mm, metal part can reach +/-0.01mm

(5). Payment Terms: L/C, T/T, Paypal&Western Union is acceptable.

(6). Packagings: Standard package/ Pallet or container/As per customized specifications.

(7). Shipment Terms: Express&air freight priority/sea freight/ As per customized specifications.

7. Our Advantages:

(1). Advance machine and the skillful workers

(2). Low MOQ (1-10PCS is even acceptable in some special conditions)

(3). Short lead time (7-30days according to order qty)

(4). Customized size and drawing is available

(5). Near shenzhen and HK, convenient transportation

(6). Have own the factory and the material price from wholesale

8. Currently market:

USA, Argentina, Canana, Australia, New Zealand, UK, France, HK, Singapore, Malaysia and so on...

We established strong relationships with our customers with unsurpassed customer support and a total commitment to quality and on time delivery. From the design phase to the parts and components being delivered to our customers, we take pride in the fact that we offer unprecedented integration and service to our customers.

9. FAQ:

(1). Question---Are you the trading company or factory?

Answer-----We have our own factory!

(2). Question---What`s the production capacity for your company?

Answer---Normally can reach 20, 0000 piecs annual.

(3). Question---How about the delivery time?

Answer---The delivery time will according to the part quantity, usually sample will need 7-10 days, and part production will need 25-30 days!

(4). Question---What`s the Scrap rate for the part?

Answer---The part we offer you will be 100% inspected by our quality department, so the parts we sent you will be qualified, it mean that the scrap rate is Zero

(5). Question---What we should do if we check out the part problem?

Answer---If you have recieved any unqualified part, you can take the pictures and sent to me, I will check it with our engineer. Then, we will redo them for free.

10.Contact us:

If you prefer to know more about us,email or call me,let` talk more!

Looking forward to establish the long term and friendly bussiness relationship with you and esteem company.

| Equipment | Tolerance | Quantity |

| Centre Turning machine | +/-0.01-0.02mm | 6 |

| Centre Milling machine | +/-0.03mm | 6 |

| CNC turning machine | +/-0.01-0.02mm | 10 |

| CNC milling machine | +/-0.01-0.03mm | 8 |

| CNC turning &milling machine | +/-0.01-0.02mm | 3 |

| Four-axis milling machine | +/-0.01mm | 3 |

| Tapping machine | +/-0.01mm | 3 |

| Grinding machine | +/-0.002mm | 3 |

| Drilling machine | +/-0.01mm | 4 |

| Electronic discharge machine | +/-0.03mm | 3 |

| CMM | +/-0.001mm | 2 |

| Projector | +/-0.01mm | 2 |

| Hardened machine | * | 1 |

| Height Indicator | +/-0.01mm | 3 |

| Caliper | +/-0.01mm | 35 |

Related Keywords

Related Keywords

You May Also Like

You May Also Like