Sintered NdFeB Magnets

- Payment Type:

- L/C

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Shenzhen |

|---|---|

| Payment Type: | L/C |

Product Description

Product Description

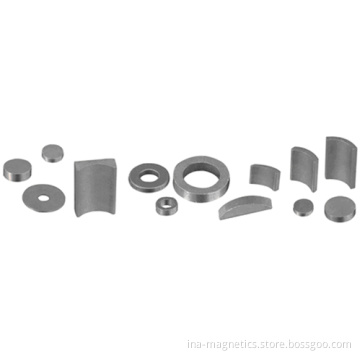

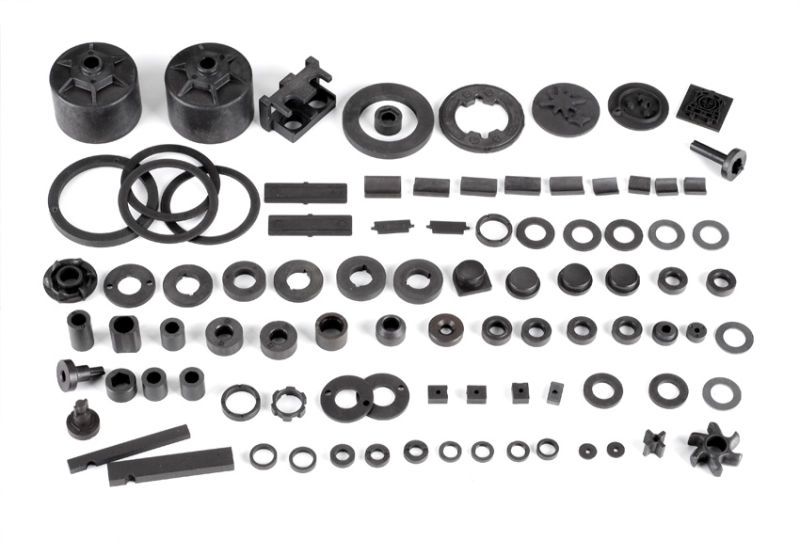

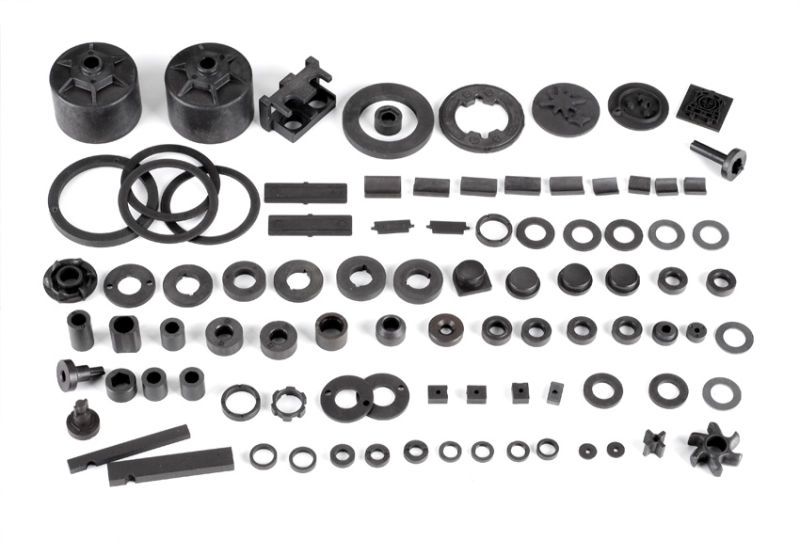

Sintered Magnets

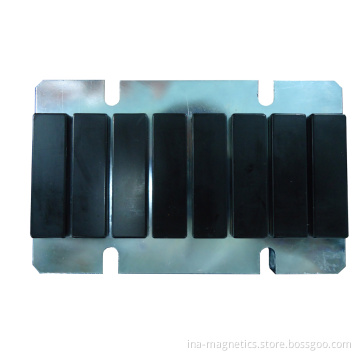

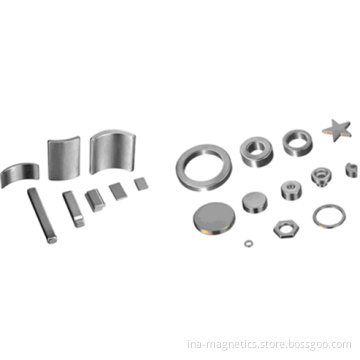

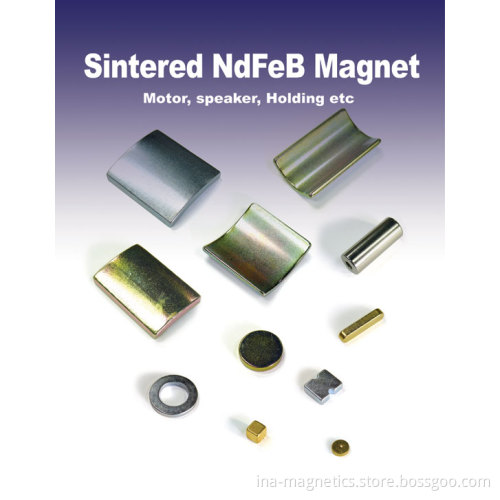

Sintered NdFeB magnets

Sintered neodymium-iron-boron (NdFeB) is the highest magnetism performance permanent-magnet material at present. We can provide the sintered NdFeB magnets whose (BH) value can reach to 52 MGOe. Protective coating is necessary for the sintered NdFeB magnets. The temperature stability of the sintered NdFeB magnets has been improved, the maximum operation temperature of them can reach to 230 c.

Sintered NdFeB magnets

Sintered neodymium-iron-boron (NdFeB) is the highest magnetism performance permanent-magnet material at present. We can provide the sintered NdFeB magnets whose (BH) value can reach to 52 MGOe. Protective coating is necessary for the sintered NdFeB magnets. The temperature stability of the sintered NdFeB magnets has been improved, the maximum operation temperature of them can reach to 230 c.

Sintered ferrite magnets

The sintered ferrites are the most widely used magnets due to their low cost. They are available in isotropic magnet and anisotropic magnet. Isotropic ferrite magnets can be magnetized in many different directions or in multi-poles. Anisotropic ferrite magnets can only be magnetized along a preferred direction. The sintered ferrites have an excellent resistance to demagnetization, good corrosion resistance and high hardness, but their temperature coefficient is poor and they can be broken easily.

Sintered SmCo magnets

The maximum operation temperature of SmCo materials is between 250 c~350 c. The SmCo materials have good corrosion resistance and lower magnetic flux loss in high temperature environment compared with other kinds of permanent magnet materials. They are especially suitable in high-temperature, high-humidity and corrosive environment.

Sintered/casted AINiCo magnets

The AINico permanent magnet materials have higher residual magnet, their coercive force is low, and they have good corrosion resistance and excellent temperature stability.

The sintered ferrites are the most widely used magnets due to their low cost. They are available in isotropic magnet and anisotropic magnet. Isotropic ferrite magnets can be magnetized in many different directions or in multi-poles. Anisotropic ferrite magnets can only be magnetized along a preferred direction. The sintered ferrites have an excellent resistance to demagnetization, good corrosion resistance and high hardness, but their temperature coefficient is poor and they can be broken easily.

Sintered SmCo magnets

The maximum operation temperature of SmCo materials is between 250 c~350 c. The SmCo materials have good corrosion resistance and lower magnetic flux loss in high temperature environment compared with other kinds of permanent magnet materials. They are especially suitable in high-temperature, high-humidity and corrosive environment.

Sintered/casted AINiCo magnets

The AINico permanent magnet materials have higher residual magnet, their coercive force is low, and they have good corrosion resistance and excellent temperature stability.

Related Keywords

Related Keywords