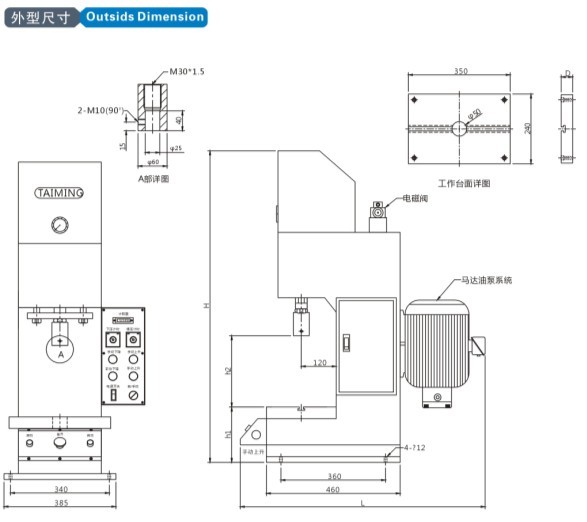

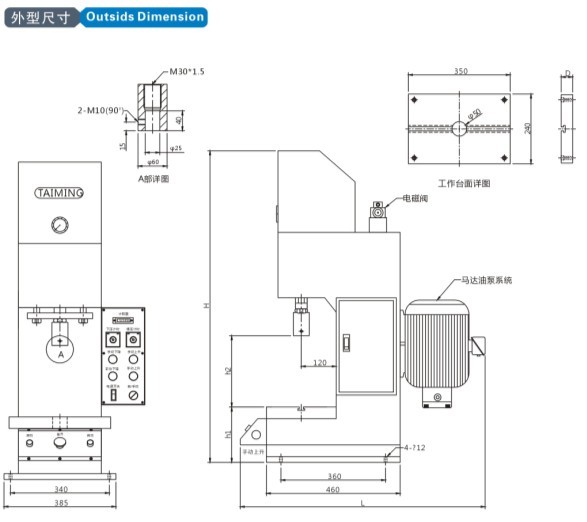

XTM-103C series of C-type hydraulic machine

- Delivery Time:

- 60 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

XTM103C series C type hydraulic press:

Scope of application: (precision C type hydraulic press, bow hydraulic machine, precision hydraulic machine, small hydraulic machine, span type liquid presses, hydraulic pressing machine, auto parts pressure into the machine)

This series hydraulic presses are widely applied to various materials of punching, stamping, plastic, riveting. Bending, shear, tensile, a variety of small parts of the press fit, assembly. A multi-purpose press,. The series press is a applicability of single shaft assembly equipment, set pressure, hydraulic advantages for a body, is the vast number of manufacturers to improve the quality of the product is preferred.

Product features:

1. The series hydraulic press to 1-15MPA liquid pressure as the power source, external three-phase AC380V 50Hz or AC220 60Hz three-phase AC power supply. The total power consumption does not exceed 3.7KW.

The 2 series of equipment to liquid as the medium to transmit energy, flexible control, easy realization of automation, running speed

Smooth uniform, and pneumatic equipment, speed and pressure can be adjusted and controlled, output adjustment range, strong independence, more stable performance, greatly improve the product assembling quality.

The noise does not exceed 80 dB 3 equipment standby.

4 the whole welding solid open type structure, can make the body to maintain adequate steel, also has the most convenient operating space.

5. Break up and semi-automatic two control modes, manual can be pressing die stopped at arbitrary distance range, equipped with emergency recovery button, the installation of infrared hand device.

6. The series press pressing stroke by the timer, pressure switch, position sensor, or the customers own mold control.

7 pressing spindle rebound height, through the timer, or position sensor arbitrary stroke range adjustment.

Drop 8 spindle rebound speed uniform for 3tf 90MM/S, 5tf 75MM/S, 10tf 68MM/S.

9 the pressure, stroke, pressure holding time, customers can adjust the shut height, convenient operation;

10 hydraulic system built-in frame, neat appearance, lightweight, and stable.

11 with automatic counting function, but also with force measuring display, customized according to customer requirements,

The 12 series of hydraulic machinery power range 3tf. 5tf. 10tf. (1tf=1000kgf=9.8KN) optional.

Features: pressure and stroke adjustable, using dynamic and automatic control mode, according to the process need optional timing or process control set. Convenient operation, reliable work.

Scope of application: this series hydraulic press apply in parts of the press assembly and parts of the correction and riveting; also applies to plastic materials, sheet metal forming, such as sheet metal falling material, drawing, stamping and plastic and powder products, pressing and other purposes.

Scope of application: (precision C type hydraulic press, bow hydraulic machine, precision hydraulic machine, small hydraulic machine, span type liquid presses, hydraulic pressing machine, auto parts pressure into the machine)

This series hydraulic presses are widely applied to various materials of punching, stamping, plastic, riveting. Bending, shear, tensile, a variety of small parts of the press fit, assembly. A multi-purpose press,. The series press is a applicability of single shaft assembly equipment, set pressure, hydraulic advantages for a body, is the vast number of manufacturers to improve the quality of the product is preferred.

Product features:

1. The series hydraulic press to 1-15MPA liquid pressure as the power source, external three-phase AC380V 50Hz or AC220 60Hz three-phase AC power supply. The total power consumption does not exceed 3.7KW.

The 2 series of equipment to liquid as the medium to transmit energy, flexible control, easy realization of automation, running speed

Smooth uniform, and pneumatic equipment, speed and pressure can be adjusted and controlled, output adjustment range, strong independence, more stable performance, greatly improve the product assembling quality.

The noise does not exceed 80 dB 3 equipment standby.

4 the whole welding solid open type structure, can make the body to maintain adequate steel, also has the most convenient operating space.

5. Break up and semi-automatic two control modes, manual can be pressing die stopped at arbitrary distance range, equipped with emergency recovery button, the installation of infrared hand device.

6. The series press pressing stroke by the timer, pressure switch, position sensor, or the customers own mold control.

7 pressing spindle rebound height, through the timer, or position sensor arbitrary stroke range adjustment.

Drop 8 spindle rebound speed uniform for 3tf 90MM/S, 5tf 75MM/S, 10tf 68MM/S.

9 the pressure, stroke, pressure holding time, customers can adjust the shut height, convenient operation;

10 hydraulic system built-in frame, neat appearance, lightweight, and stable.

11 with automatic counting function, but also with force measuring display, customized according to customer requirements,

The 12 series of hydraulic machinery power range 3tf. 5tf. 10tf. (1tf=1000kgf=9.8KN) optional.

Features: pressure and stroke adjustable, using dynamic and automatic control mode, according to the process need optional timing or process control set. Convenient operation, reliable work.

Scope of application: this series hydraulic press apply in parts of the press assembly and parts of the correction and riveting; also applies to plastic materials, sheet metal forming, such as sheet metal falling material, drawing, stamping and plastic and powder products, pressing and other purposes.

Related Keywords

Related Keywords

You May Also Like

You May Also Like