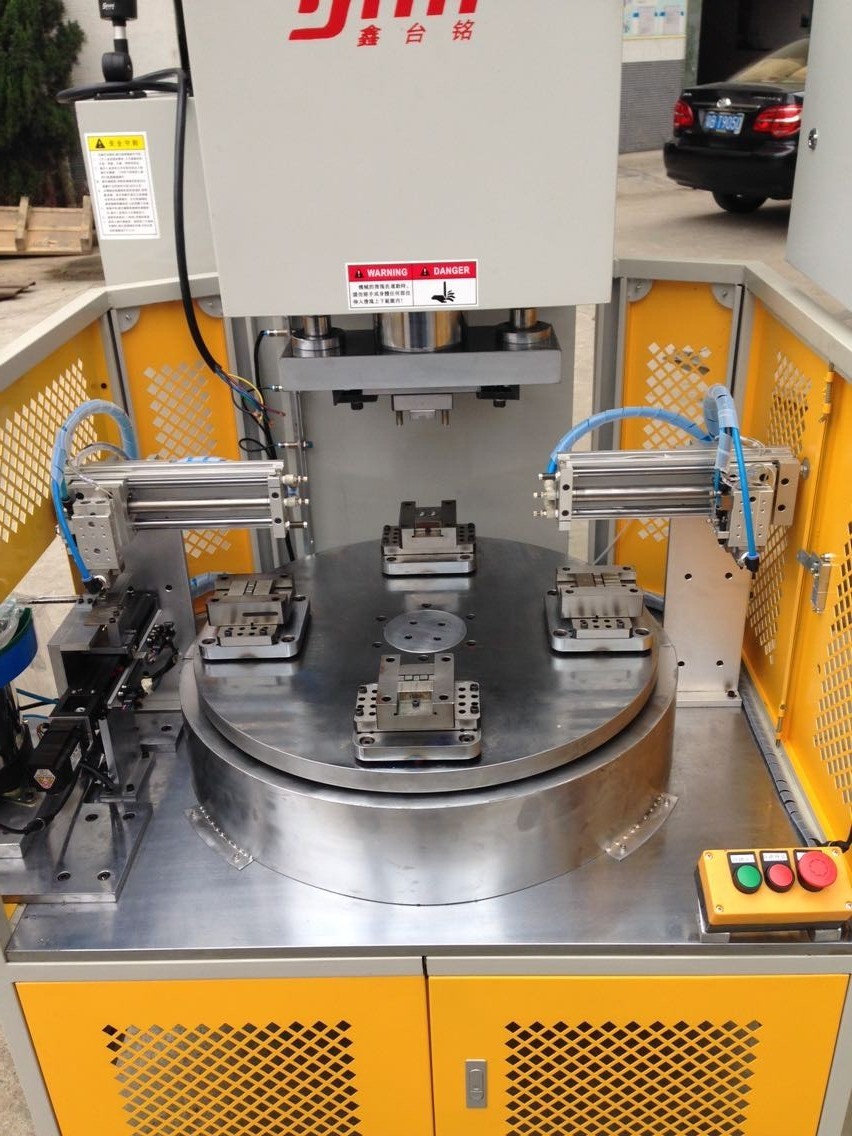

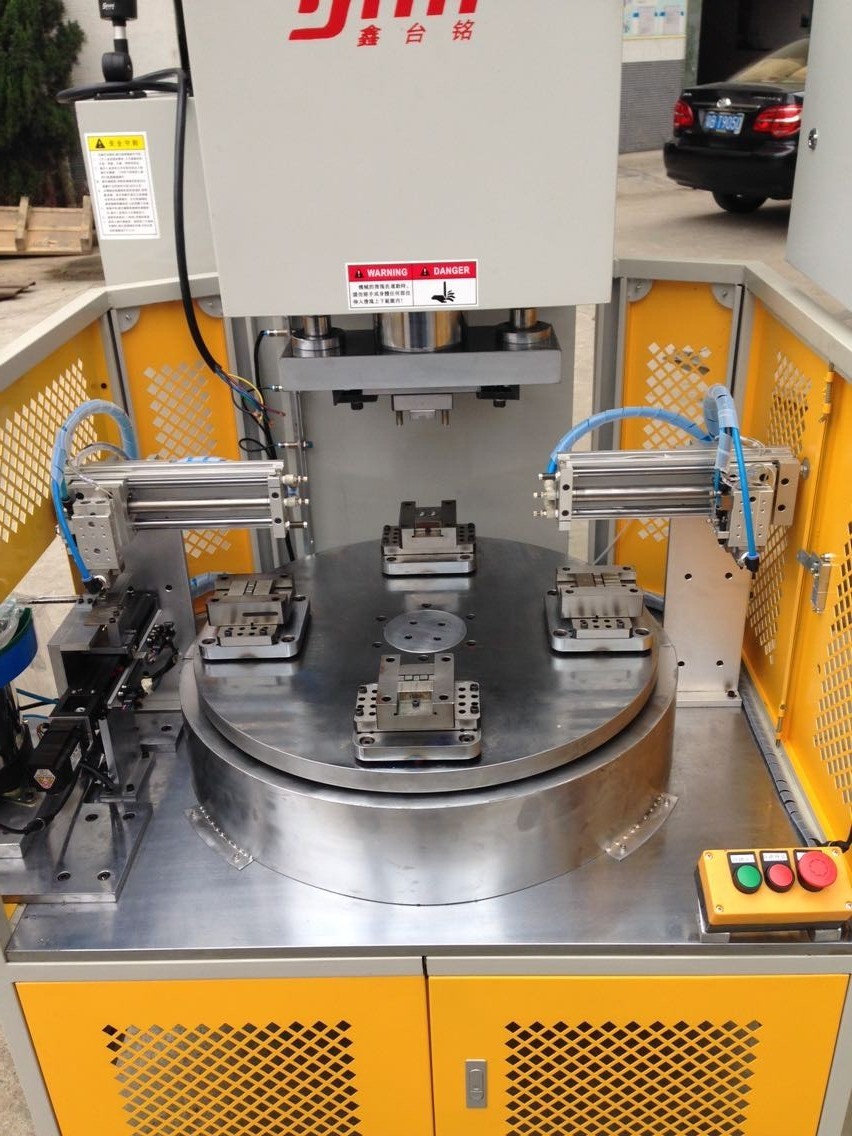

MIM full automatic hydraulic shaping machine hydraulic shaping machine

- Delivery Time:

- 35 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

MIM full automatic hydraulic shaping machine

MIM hydraulic shaping machine, also known as: MIM MIM shaping machine, full automatic shaping machine, MIM punch, MIM press, MIM shaping oil press, MIM hydraulic shaping machine, MIM hydraulic shaping machine, MIM hydraulic shaping machine, metal plastic injection machine, MIM processing equipment, camera trim shaping machine, card slot shaper, Cato shaping machine, mobile phone card slot shaper, Cato handset shaping machine, commutator shaping machine, commutator split hook machine, commutator stripping machine, commutator of non-standard equipment.

By Xin Tai Ming independent R & D and production of MIM hydraulic shaping machine is my company for MIM (metal powder without injection molding technology) and PM, PIM shaping process and the development of professional equipment, using high quality hydraulic components and advanced circuit design. The stable pressure, data tracking, real-time monitoring of the parameters and pressure curve and quality monitoring, data export functions. Two mechanical and CNC devices choice.

The MIM process is: first solid powder and organic binder is mixed uniformly practice, after pelletization in heating plasticized by injection molding machine injection mold cavity curing forming, then using chemical or thermal decomposition method will be forming in casting binder removal, the Sintering Densification by the final product.

MIM products not only has the shape of plastic injection molding process is complex, easy to mass production, and with precision casting, forging close to the physical, chemical and mechanical properties, preparation has a complicated three-dimensional geometry, homogeneous microstructure and high performance of near net forming products with unique advantages in. Features of MIM products:

1, the degree of freedom of the parts and components of the high degree of freedom, like the production of plastic products, the production of a complex shape metal parts,

2, MIM product density uniformity, good finish, the surface roughness can reach Ra 0.80 ~ 1.6 m, weight range of 0.1 ~ 200g. High dimensional accuracy (+ 0.1% ~ + 0.3%), generally do not require subsequent processing.

3, suitable for wide range of materials, wide range of application, high raw material utilization rate, high degree of automation, the process is simple, can achieve continuous mass production.

4, the product quality is stable, the performance is reliable, the relative density of the product can reach 95% ~ 99%, can carry on the heat treatment of carburizing, quenching, tempering, etc.. Product strength, hardness, elongation and other mechanical properties, such as high mechanical properties, good wear resistance, fatigue resistance, uniform organization

It is generally believed that the development of MIM technology will lead to a revolution in parts forming and processing technology, known as the forming technology of the hottest parts in twenty-first Century ". Therefore, it is generally believed that the development of MIM technology will lead to a revolution in parts forming and processing technology, known as "the most popular parts forming technology" and "forming technology" in twenty-first Century ". Metal injection molding (metal injection molding (MIM) is will modern plastic injection forming technology into the field of powder metallurgy and the formation of a new metal parts near net shape forming technology, in recent years, powder metallurgy disciplines and industrial sectors in developing very rapidly in a new and high technology.

Automatic metal injection molding machine: the need to process products and equipment: according to the actual product design.

Work flow:

1 the workpiece on the artificial vibration plate, and press the start button;

2 vibration plate will be sent to the workpiece feeding mechanism, and in accordance with the requirements of row;

3 the workpiece is removed from the workpiece and placed in the tool;

4 rotary disk work, will be put to work to press the position of the workpiece;

5 hydraulic press action to complete the work of the pressure loading, while feeding on the mechanical hand;

The 6 rotary disk is pressed to the workpiece to be sent to the next station, and the material is removed by the manipulator;

Repeat above action.

Characteristics of equipment:

1, high efficiency, time saving, labor saving;

2, improve product quality, quality and stability;

3, product compatibility, high stability;

4, centralized and interlocking control;

Automatic shaping mechanism:

The hydraulic press (hydraulic press), the hydraulic press with the mold to use, to achieve the effect of pressure shaping.

Rotating station (dividing plate), transfer the role of the workpiece.

The automatic feeding device, reclaimer (manipulator, vibration plate), loading and unloading, workpiece transfer function.

The control part, the use of PLC and touch screen

Automatic plastic machine application products:

Now widely used in commonly used spare parts of electronic products, such as mobile phones, IPD and camera trim, phone cards groove, Cato and other small parts (MIM metal injection), at present the company Tongda Group, Jin Sheng group's has gradually use automatically. Shaping machine to improve efficiency (before the use of ordinary hydraulic machine production).

MIM hydraulic shaping machine, also known as: MIM MIM shaping machine, full automatic shaping machine, MIM punch, MIM press, MIM shaping oil press, MIM hydraulic shaping machine, MIM hydraulic shaping machine, MIM hydraulic shaping machine, metal plastic injection machine, MIM processing equipment, camera trim shaping machine, card slot shaper, Cato shaping machine, mobile phone card slot shaper, Cato handset shaping machine, commutator shaping machine, commutator split hook machine, commutator stripping machine, commutator of non-standard equipment.

By Xin Tai Ming independent R & D and production of MIM hydraulic shaping machine is my company for MIM (metal powder without injection molding technology) and PM, PIM shaping process and the development of professional equipment, using high quality hydraulic components and advanced circuit design. The stable pressure, data tracking, real-time monitoring of the parameters and pressure curve and quality monitoring, data export functions. Two mechanical and CNC devices choice.

The MIM process is: first solid powder and organic binder is mixed uniformly practice, after pelletization in heating plasticized by injection molding machine injection mold cavity curing forming, then using chemical or thermal decomposition method will be forming in casting binder removal, the Sintering Densification by the final product.

MIM products not only has the shape of plastic injection molding process is complex, easy to mass production, and with precision casting, forging close to the physical, chemical and mechanical properties, preparation has a complicated three-dimensional geometry, homogeneous microstructure and high performance of near net forming products with unique advantages in. Features of MIM products:

1, the degree of freedom of the parts and components of the high degree of freedom, like the production of plastic products, the production of a complex shape metal parts,

2, MIM product density uniformity, good finish, the surface roughness can reach Ra 0.80 ~ 1.6 m, weight range of 0.1 ~ 200g. High dimensional accuracy (+ 0.1% ~ + 0.3%), generally do not require subsequent processing.

3, suitable for wide range of materials, wide range of application, high raw material utilization rate, high degree of automation, the process is simple, can achieve continuous mass production.

4, the product quality is stable, the performance is reliable, the relative density of the product can reach 95% ~ 99%, can carry on the heat treatment of carburizing, quenching, tempering, etc.. Product strength, hardness, elongation and other mechanical properties, such as high mechanical properties, good wear resistance, fatigue resistance, uniform organization

It is generally believed that the development of MIM technology will lead to a revolution in parts forming and processing technology, known as the forming technology of the hottest parts in twenty-first Century ". Therefore, it is generally believed that the development of MIM technology will lead to a revolution in parts forming and processing technology, known as "the most popular parts forming technology" and "forming technology" in twenty-first Century ". Metal injection molding (metal injection molding (MIM) is will modern plastic injection forming technology into the field of powder metallurgy and the formation of a new metal parts near net shape forming technology, in recent years, powder metallurgy disciplines and industrial sectors in developing very rapidly in a new and high technology.

Automatic metal injection molding machine: the need to process products and equipment: according to the actual product design.

Work flow:

1 the workpiece on the artificial vibration plate, and press the start button;

2 vibration plate will be sent to the workpiece feeding mechanism, and in accordance with the requirements of row;

3 the workpiece is removed from the workpiece and placed in the tool;

4 rotary disk work, will be put to work to press the position of the workpiece;

5 hydraulic press action to complete the work of the pressure loading, while feeding on the mechanical hand;

The 6 rotary disk is pressed to the workpiece to be sent to the next station, and the material is removed by the manipulator;

Repeat above action.

Characteristics of equipment:

1, high efficiency, time saving, labor saving;

2, improve product quality, quality and stability;

3, product compatibility, high stability;

4, centralized and interlocking control;

Automatic shaping mechanism:

The hydraulic press (hydraulic press), the hydraulic press with the mold to use, to achieve the effect of pressure shaping.

Rotating station (dividing plate), transfer the role of the workpiece.

The automatic feeding device, reclaimer (manipulator, vibration plate), loading and unloading, workpiece transfer function.

The control part, the use of PLC and touch screen

Automatic plastic machine application products:

Now widely used in commonly used spare parts of electronic products, such as mobile phones, IPD and camera trim, phone cards groove, Cato and other small parts (MIM metal injection), at present the company Tongda Group, Jin Sheng group's has gradually use automatically. Shaping machine to improve efficiency (before the use of ordinary hydraulic machine production).

Related Keywords

Related Keywords

You May Also Like

You May Also Like