Deep Throat Bearing Assembly Machine, Hydraulic Assembly Machine

- Delivery Time:

- 15 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China (Mainland) |

|---|

Product Description

Product Description

Specifications Bearing Assembly Machine

1.CE,ISO approved

2.10 years' manufacturing&8 years' exporting experience

3.suitable production line

Deep Throat Bearing Assembly Machine, Hydraulic Assembly Machine Product Description 1. Monoblock,Welded steel frame rigid to reduce deflection movment.

1. Monoblock,Welded steel frame rigid to reduce deflection movment.

2. C-frame design for large operating spaces suitable for automatic production line . 3. Adopts advanced dual oil cylinder,can achieve the function of rapidly close and slowly press. 4. Operated by double-button switch. 5. Selector switch modes of operation: jog (setup) and run (cycle). 6. Flexibly adjustable pressure dwell time and stroke. 7. Ideal of double SLC(Security Light Curtain) makes it safe of operation. 8. Front Side Covers with emergencey switches;Protective fence and the safety interlock can be added to upgrade the secure. 9. All pipes, flange and joint with vibrations proof and leakage proof design and setting . 1. Punching,embossing,forming,shallow drawing,shaping,riveting,bending,shearing,tension and assembling of metal or nonmetal. 2. Press fitting of motor rotors,stators,electronic connectors and electric parts. 3. Press fitting of various kinds of small parts,ect.

1. Punching,embossing,forming,shallow drawing,shaping,riveting,bending,shearing,tension and assembling of metal or nonmetal. 2. Press fitting of motor rotors,stators,electronic connectors and electric parts. 3. Press fitting of various kinds of small parts,ect.

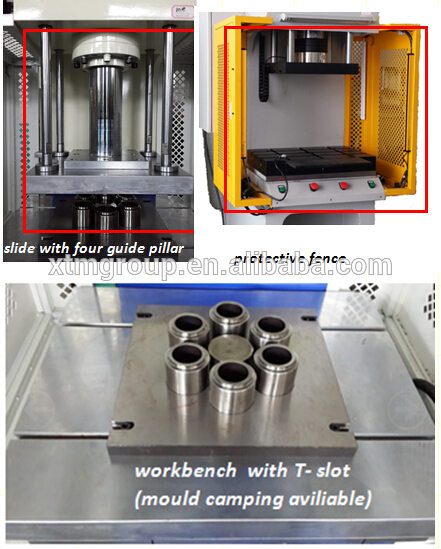

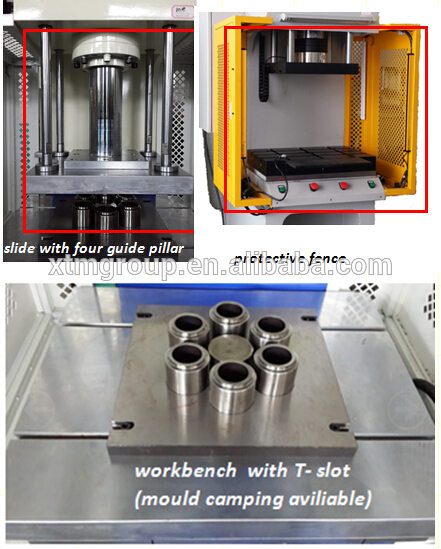

Machine Details

Company Strength Shenzhen Xintaiming Machinery Equipment Co., Ltd. is professional researching and developing manufacturer which is specialized in the designing and making Hydraulic cutting /punching/molding/bending/hot press machine High speed punching machine CNC C-type hydraulic machine CNC Servo press series IMD/IML hot press molding machine IMD/IML 3D punching machine and so on

Company Strength Shenzhen Xintaiming Machinery Equipment Co., Ltd. is professional researching and developing manufacturer which is specialized in the designing and making Hydraulic cutting /punching/molding/bending/hot press machine High speed punching machine CNC C-type hydraulic machine CNC Servo press series IMD/IML hot press molding machine IMD/IML 3D punching machine and so on  Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than 30 countries.

Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than 30 countries.

1. We master the latest hydraulic and quality control technologies and have 20 years of worldwide manufacturing experience. 2. It has nearly 200 emplyees and over 20 senior engineers and 10 quality control personel. 3.Presses can be customized to meet your specific needs and requirements. 4. The factory area is about 7500 square meters.  1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron etc. Besides. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and electrical parts performance. Meanwhile, there will be video giving to you(FAT video). 3. Any error(not man-made) happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement.

1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron etc. Besides. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and electrical parts performance. Meanwhile, there will be video giving to you(FAT video). 3. Any error(not man-made) happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement.

1.CE,ISO approved

2.10 years' manufacturing&8 years' exporting experience

3.suitable production line

Deep Throat Bearing Assembly Machine, Hydraulic Assembly Machine Product Description

1. Monoblock,Welded steel frame rigid to reduce deflection movment.

1. Monoblock,Welded steel frame rigid to reduce deflection movment. 2. C-frame design for large operating spaces suitable for automatic production line . 3. Adopts advanced dual oil cylinder,can achieve the function of rapidly close and slowly press. 4. Operated by double-button switch. 5. Selector switch modes of operation: jog (setup) and run (cycle). 6. Flexibly adjustable pressure dwell time and stroke. 7. Ideal of double SLC(Security Light Curtain) makes it safe of operation. 8. Front Side Covers with emergencey switches;Protective fence and the safety interlock can be added to upgrade the secure. 9. All pipes, flange and joint with vibrations proof and leakage proof design and setting .

1. Punching,embossing,forming,shallow drawing,shaping,riveting,bending,shearing,tension and assembling of metal or nonmetal. 2. Press fitting of motor rotors,stators,electronic connectors and electric parts. 3. Press fitting of various kinds of small parts,ect.

1. Punching,embossing,forming,shallow drawing,shaping,riveting,bending,shearing,tension and assembling of metal or nonmetal. 2. Press fitting of motor rotors,stators,electronic connectors and electric parts. 3. Press fitting of various kinds of small parts,ect.

| model | theoretic output pressure(Ton) | operating surface size(mm) | max.operating height (mm) | cylinder stroke(mm) | cylinder desending speed(mm/s) | cylinder compressing speed(mm/s) | cylinder ascending speed(mm/s) | power supply | motor power(kw) |

| XTM-107K-10T | 3-10 | 500*400 | 400 | 200 | 65 | 20 | 75 | 3Ø380V,50/60Hz | 3.75 |

| XTM-107K-15T | 5-15 | 500*400 | 400 | 200 | 180 | 30 | 150 | 3Ø380V,50/60Hz | 2.25 |

| XTM-107K-20T | 5-20 | 600*400 | 400 | 200 | 180 | 30 | 150 | 3Ø380V,50/60Hz | 2.25 |

| XTM-107K-30T | 10-30 | 600*400 | 400 | 200 | 150 | 20 | 130 | 3Ø380V,50/60Hz | 3.75 |

| Machine Parts |

| Brands of Accessories |

Company Strength Shenzhen Xintaiming Machinery Equipment Co., Ltd. is professional researching and developing manufacturer which is specialized in the designing and making Hydraulic cutting /punching/molding/bending/hot press machine High speed punching machine CNC C-type hydraulic machine CNC Servo press series IMD/IML hot press molding machine IMD/IML 3D punching machine and so on

Company Strength Shenzhen Xintaiming Machinery Equipment Co., Ltd. is professional researching and developing manufacturer which is specialized in the designing and making Hydraulic cutting /punching/molding/bending/hot press machine High speed punching machine CNC C-type hydraulic machine CNC Servo press series IMD/IML hot press molding machine IMD/IML 3D punching machine and so on  Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than 30 countries.

Our products have been exported to Germany, Hungary, Russia, India, Indonesia, Thailand, Vietnam, the United States, Mexico, Brazil Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more than 30 countries. | Why choose us? |

1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron etc. Besides. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and electrical parts performance. Meanwhile, there will be video giving to you(FAT video). 3. Any error(not man-made) happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement.

1. We use the world-famous brand accessories like Mitsubishi, Schneider, Siemens, Yuken, Omron etc. Besides. Before packing machine, we debug machine by letting the machine run for 12 hours. 2. Before packing machine, the machine will run one day for testing oil leakage, repeat error, and electrical parts performance. Meanwhile, there will be video giving to you(FAT video). 3. Any error(not man-made) happens within the period of guarantee, we offer the according parts for free. 4. we will offer overseas service if we(the Two Parties) can come to an overseas service agreement. Related Keywords

Related Keywords

You May Also Like

You May Also Like