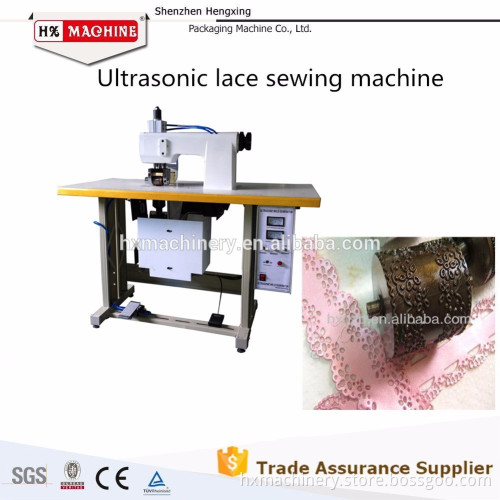

Ultrasonic Sewing Machine For Textile Fabric

- Delivery Time:

- 10 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Guangdong, China (Mainland) |

|---|

Product Description

Product Description

Ultrasonic Sewing Machine For Textile Fabric To different Country!!!  Product Description Application This machine can be used to all kinds of fabric, artificial leather, coated cotton, PE paper, PE + aluminum, PE+ cloth and other compound materials, thermoplastic plastics foil film and plastic sheet. all chemical synthetic fiber materials, or materials contain chemical fiber blending cloth, chemical film(chemical fiber should more than 30%), for instance, Nylon, needlework cloth, non-woven fabrics, T\R cloth, Tetoron cloth(Polyester cloth),multilayer cloth, and other coated fabric and coated papers. It’s widely used to all kinds of industries such as clothes, household adornment, handicraft article, toys, etc.

Product Description Application This machine can be used to all kinds of fabric, artificial leather, coated cotton, PE paper, PE + aluminum, PE+ cloth and other compound materials, thermoplastic plastics foil film and plastic sheet. all chemical synthetic fiber materials, or materials contain chemical fiber blending cloth, chemical film(chemical fiber should more than 30%), for instance, Nylon, needlework cloth, non-woven fabrics, T\R cloth, Tetoron cloth(Polyester cloth),multilayer cloth, and other coated fabric and coated papers. It’s widely used to all kinds of industries such as clothes, household adornment, handicraft article, toys, etc.  Parameters

Parameters

Features and Functions 1. Ultrasonic lace sewing machine used ultrasonic vibration and steel moulds, the processing will be finished with pressure. 2. There’s no fog and spark in produce processing, won't cause damage to fabric edge, and also can avoid deckle edge. 3. Chang of the ultrasonic cutting die is very easy, and the design of the moulds can be made according to customer’s requirement. 4. Without pre-heating, and continuous operation is possible. 5. Colored paper and gold foil paper be added in order to get the effect of printing and hot stamping. 6. Machines can be combined to one set of equipments in order to sew large width products once, for instance, guilt cover, gingham, etc. 7. The cutting moulds (cutting die) that be made of special alloy steel which has been treated with special heat treatment technology, so the moulds with high wear resistance and gains a longer service life. 8. Simple operation, easy repair, using 20KHZ low noise ultrasonic to avoid noise disturbed. Mould and Samples:

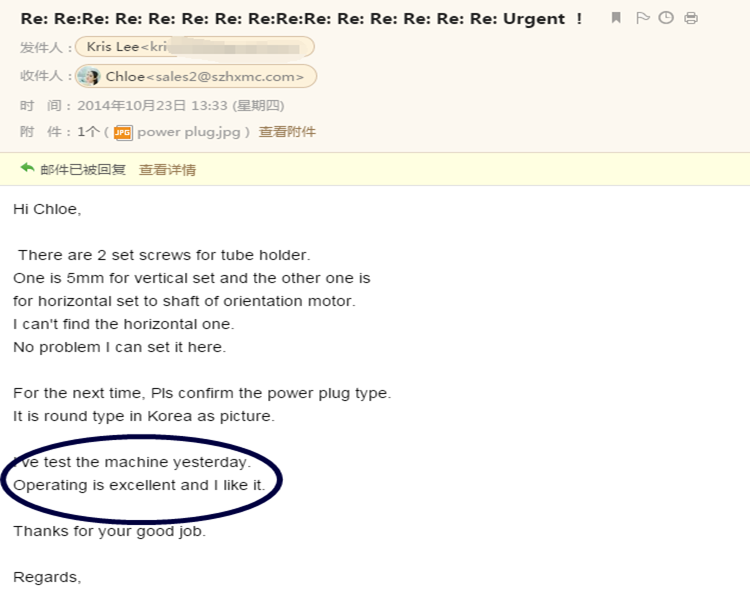

Customer feedback:

Customer feedback:

Factory view:

Factory view:  Company Information

Company Information

Packaging & Shipping

Packaging & Shipping  FAQ

FAQ  Contact us

Contact us

Product Description Application This machine can be used to all kinds of fabric, artificial leather, coated cotton, PE paper, PE + aluminum, PE+ cloth and other compound materials, thermoplastic plastics foil film and plastic sheet. all chemical synthetic fiber materials, or materials contain chemical fiber blending cloth, chemical film(chemical fiber should more than 30%), for instance, Nylon, needlework cloth, non-woven fabrics, T\R cloth, Tetoron cloth(Polyester cloth),multilayer cloth, and other coated fabric and coated papers. It’s widely used to all kinds of industries such as clothes, household adornment, handicraft article, toys, etc.

Product Description Application This machine can be used to all kinds of fabric, artificial leather, coated cotton, PE paper, PE + aluminum, PE+ cloth and other compound materials, thermoplastic plastics foil film and plastic sheet. all chemical synthetic fiber materials, or materials contain chemical fiber blending cloth, chemical film(chemical fiber should more than 30%), for instance, Nylon, needlework cloth, non-woven fabrics, T\R cloth, Tetoron cloth(Polyester cloth),multilayer cloth, and other coated fabric and coated papers. It’s widely used to all kinds of industries such as clothes, household adornment, handicraft article, toys, etc.  Parameters

Parameters Item | Parameter |

Model | HX-2012RFS |

Power supply | 220V/50HZ |

Power | 1200W |

Frequency | 20Khz |

Welding width | 1.0-48mm |

System | Taiwan style |

N.W | 100kgs |

G.W | 120kgs |

Machine size | 1200*600*1000mm |

Pack | Plywood |

Customer feedback:

Customer feedback:

Factory view:

Factory view:  Company Information

Company Information

Packaging & Shipping

Packaging & Shipping  FAQ

FAQ  Contact us

Contact us

Related Keywords

Related Keywords

You May Also Like

You May Also Like