Powder coating spray machine

- Payment Type:

- L/C, T/T, Western Union

- Incoterm:

- FOB, CIF, EXW, FCA

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 600 |

| Supply Ability: | 50 |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CIF,EXW,FCA |

| Certificate: | CE ISO |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

Powder coating spray machine

Product Application

Stainless steel powder buckets are made for food and materials. Alternate heat and cold do not break.

|

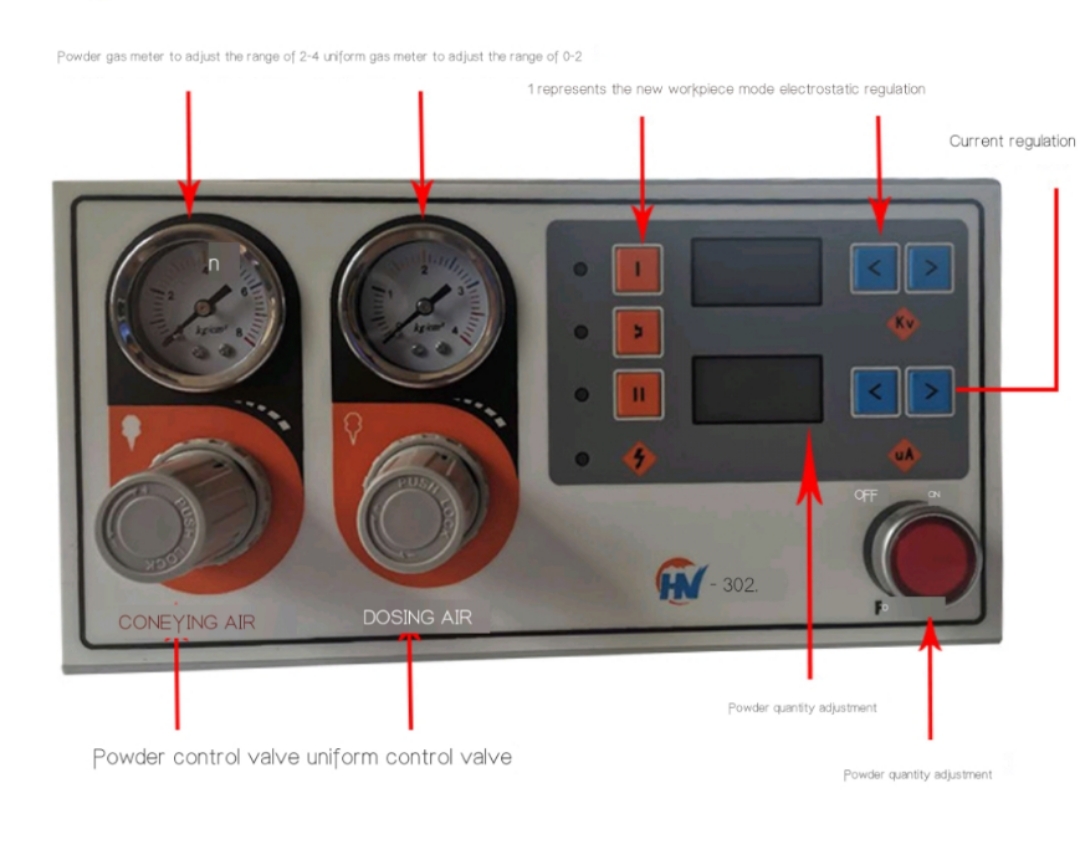

Electronic controller

|

Pneumatic controller

|

Powder spray gun

|

|

|

voltage pressure 220v / 50hz

|

Solenoid valve control voltage :DC24

|

Powder gun weight: about 450 g

|

|

|

Input power :AC220V/50HZ

|

Output pressure :0-0.6111Pa

|

safety standard: 1 p54

|

|

|

Input voltage: 0-100vac

|

Water content less than 1g/m?Air requirement: oil content less than 0.01g/m2

|

powder output: llla x 500 g/min

|

|

GUIDE

1. The connection of the compressed air supply. Connect directly from the compressed air line to the main air connection point at the rear of the control unit (Φ8 x PU tube)

Compressed air must be oil-free & water-free.

2. Use an air tube to connect the fluidized air outlet at the rear of the control unit and the fluidized air pressure reducing valve on the moving cart.

3. Grounding screw fix the grounding cable to the grounding point of the control unit, and clamp the collet of the 5 m long grounding cable to the spray booth or suspension equipment.

4. Connect the gun cable to the socket(gun) at the rear of the control unit with a 5-pin connector .

5. Connect spray gun, clean air output tube.

6. Insert the powder pump, connect the powder gun and the powder pump tube.

7. Connect the air delivery tube to the corresponding position on the rear of the controller and the powder supply pump

8. Connect the air supplementary tube to the corresponding position at the rear of the controller and the powder supply pump

9. Connect the main power supply to the interface as shown in the figure below. (SPRAY GUN installation diagram)

Main Features

1, the surface of the product is relatively rough, the paint can not level to make up for this defect, and the thickness of the powder is relatively thick, which can effectively fill and repair some of the defects of the parts themselves;

2 the surface of the product is more pinholes, the paint is prone to pinholes or bubbles, etc. Problems, if the appropriate temperature of thermal spray powder, this defect will improve a lot;

3, dusting can prevent corrosion of the surface of iron parts

Machine Parts

Name: reciprocating powder coating guns

Brand: HENGYIJIA

Original: China

When the conveying air

(1) flows through the powder generator, the fluidized powder in the powder drum is sucked into the generator and sent to the spray gun through the powder paint tube (2), and the powder is charged with static electricity before being sprayed. There is also an electrostatic field between the grounded work object and the nozzle of the spray gun, and the electrostatic powder can be evenly attached to the surface of the work object.

Main Features

Name: Manual spray powder gun

Brand: HENGYIJIA

Original: China

Built-in high-intensity electrostatic module with circuit board electrostatic wall, no more difficult to spray recessed corners. The engineering plastic gun shell has high strength and long service life. User-friendly handle design reduces fatigue when holding.

Stainless steel powder buckets are made for food and materials. Alternate heat and cold do not break.

Machine Parts

Name: Automatic powder coating booth

Brand: HENGYIJIA

Original: China

The recycling cabinet has a vertical box structure with two layers in the middle and upper layers. The middle box is equipped with four paper filter cores, and the support of the pulse backflushing mechanism of the paper filter core is mounted on the bottom plate of the upper box, and the air supply cylinder and the pipeline for controlling the electromagnetic valve are placed on the wall of the upper box. A dust collecting bucket and a powder collecting trolley are fixed in the lower supporting frame, and an air extractor and an exhaust duct are arranged at the rear upper part of the cabinet.

Main Features

Name: Powder Bottom recovery system

Brand: HENGYIJIA

Original: China

The powder coating booth is stainless steel.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Related Keywords