1.5M Updated LLDPE Stretch Film Unit

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 60 Days

- Transportation:

- Ocean, Land

- Port:

- SHEKOU, CHIWAN, YANTIAN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 380kg/h |

| Supply Ability: | 20-50sets/m |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE,ISO9001:2008 |

| HS Code: | 8477209000 |

| Transportation: | Ocean,Land |

| Port: | SHEKOU,CHIWAN,YANTIAN |

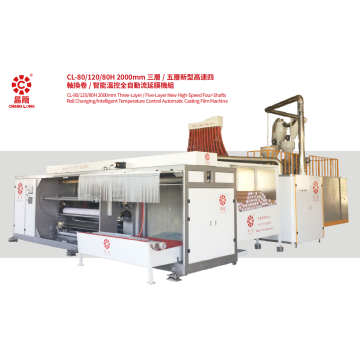

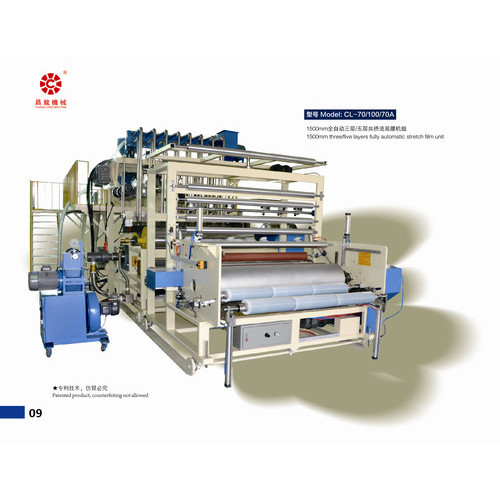

CL-70/100/70A 1.5M LLDPE Updated Stretch Film Unit

Designed for three or five layers stretch film,cling film,and protective film, this CL-70/100/70A Updated LLDPE Stretch Line Unit could be easily operated as it combines Italy and Amercian technology which help produce stretch film with high plasticity.

This CL-70/100/70A Updated LLDPE Plastic Stretch Film Unit is also improved based on our manufacturing experience and customer's actual feedback.

Advantages of CL-70/100/70A 1.5M Updated LLDPE Stretch Film Unit

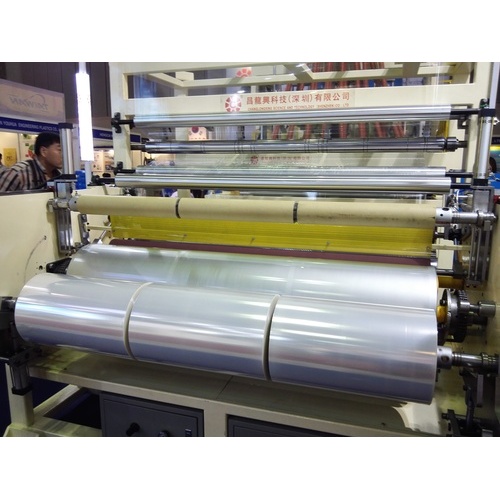

1.The Melt metering pump unit installed in this CL-70/100/70A Updated LLDPE Stretch Film Unit uses sensor technology,precise control uint extrusion pressure to achieve a linear extrusion ,improve film properties.

2.Vacuum devices in this CL-70/100/70A Updated LLDPE Stretch Film Unit makes the flow of melt raw material more close to the surface of the cooling roller which can achieve better cooling effect and thus improve film performane.

3.Installation of fence of this CL-70/100/70A Updated LLDPE Stretch Film Unit around the screw stairs makes it user friendly and it's easy to operate at any time to view the situation.

4.Touch screen centralized control,interpersoal friendly interface makes the CL-70/100/70A Updated LLDPE Stretch Film Unit simple to operate and more intelligent.

5.The products produced by the CL-70/100/70A Updated LLDPE Stretch Film Unit enjoys uniform thickness,good tensile strength,strong puncture resistencee especially meet the high-end and high quality requirements.

6.The machine CL-70/100/70A Updated LLDPE Stretch Film Unit is equipped with casting cooling section with large diameter double-loop cooling system to make the reel surface temperature uniformity,and to improve the cooling effect.

Main Technical Parameter of CL-70/100/70A 1.5M Updated LLDPE Stretch Film Unit

Model: CL-70/100/70A

Structure of Film Layers: A/B/C or A/C/B/C/A

Screw Diameter of machine CL-70/100/70A Updated LLDPE Plastic Stretch Film Unit : 70/100/70mm

Width of Die Head for CL-70/100/70A Updated 1.5m LLDPE Stretch Film Unit : 1850mm

L/D Ratio of Screw: 30:1

Motor Power of Main Machine for CL-70/100/70A Updated LLDPE Stretch Film Unit : 37/90/37kw

Linear Speed of CL-70/100/70A Updated 1.5m LLDPE Stretch Film Unit : 200m/min

Max Extrusion Capacity of CL-70/100/70A Updated 1.5m LLDPE Stretch Film Unit : 380kg/h

Max Rewind Diameter of CL-70/100/70A Updated LLDPE Stretch Film Unit : 400mm

Overall Dimensions(L*W*H) for CL-70/100/70A Updated LLDPE Plastic Stretch Film Unit : 11.5*4.3*4.5m

Total Weight : 18.2T

Width of Film Produced by CL-70/100/70A Updated LLDPE 1.5m Stretch Film Unit : 1500mm

Thickness of Film Produced by CL-70/100/70A Updated LLDPE Stretch Film Unit : 0.01-0.05mm

Certificate of CL-70/100/70A 1.5M Updated LLDPE Stretch Film Unit

After-Sales Service for CL-70/100/70A 1.5M Updated LLDPE Stretch Film Unit

We possess a professional and experienced technical team to enable our service network cover all around the world.The rapid and convenient service will meet your demands.

2. Senior engineer installation guide & operator train.

3. Machine instruction , ready access.

Warmly Welcome To Visit Our Factory

Related Keywords