New High Speed Four-shafts Roll Changing Casting Film Machine

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 80 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | ShenZhen,China |

|---|---|

| Productivity: | 560kg/h |

| Supply Ability: | 30-50sets/y |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | CE,ISO90001:2008 |

| Transportation: | Ocean |

Company Profile

Founded at Hong Kong in 1983, ChangLongXing Science&Technology(INTL)Co. , Ltd.has been committed to excellence in R&D technology,product upgrades,quality service and international development for more than 30 years. ChangLong is the well-known international brand enterprises in the field of fully automatic intelligent high-tech cast film equipment,and now also has four comprehensive and powerful group companies,leading the technological innovation and development of the domestic cast film equipment industry.

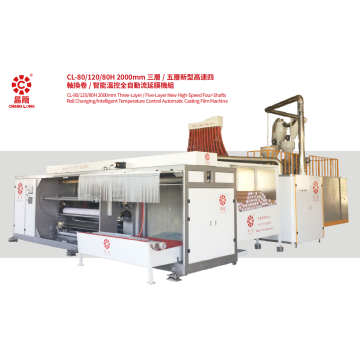

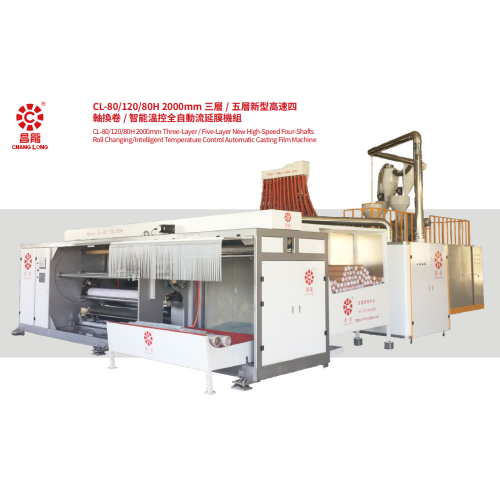

Three-Layer /Five-Layer New High-Speed Four-Shafts Roll Changing/Intelligent Temperature Control Automatic Casting Film Machine

Machine specification

1、Thickness adjustment scope:10µm-50µm;

2、Equality percent of thickness:≤±5%;

3、Width of effective film:2000mm(max) or 4*500mm ;

4、Structure of film layers:A/B/C or A/C/B/C/A Co-extruded;

5、The fit material:LLDPE,LDPE, MLLDPE;

6、Extrusion capacity(max):560kg/h.

7、Installation dimension(L*W*H): 14*6.5*4.5m

8、Weight: 25T

Characteristic

1. Self-developed vacuum rapid suction side automatic recovery device,ultra-quiet,not easy to block the material, not easy to break the edge,recovery rate.to ensure that the production is not limited by the winding speed limit,designed for the high-speed machine recycling edge stability,high recovery rate.

2. The exclusive intelligent temperature control system no longer uses the traditional thermometer,automatically adjusts the temperature,and intelligent operation saves energy.

3. The double-layer vacuum system can remove the airflow driven by the drum running and the wax gas flow generated by the high temperature of the raw materials,so that the film is tightly attached to the cooling roller and is not easy to run.

4. The combination of center and surface friction is used to rewind the film,and the film roll is more compact and flat.

5. The metering pump sensing technology precisely controls the extrusion pressure of the unit to achieve linear extrusion and improve film performance.

Application

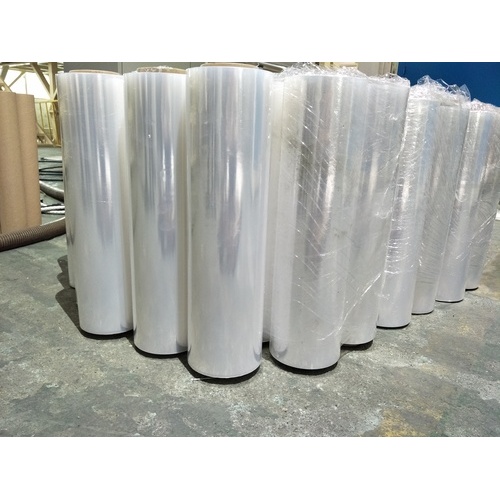

The film can be widely used in wrapping of pallet packaging, storage packaging, manual packaging and so on.

Certificate

Packaging

Company Show:

After-Sales Service

We possess a professional and young management and technicial team, our service net covers all around the world, the rapid and convenient service will meet your demands.

1. 12 months warranty period , lifelong maintenance services , engineer to door maintenance.

2. Senior engineer installation guide & operator train.

3. Machine instruction , ready access.

4. Technical service team , 7*24h telephone service.

Related Keywords