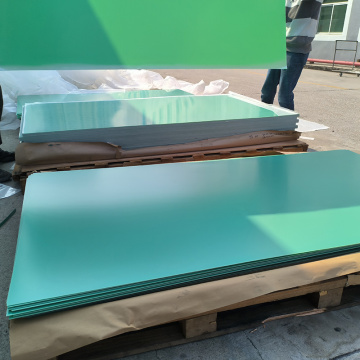

Engineering Plastics Copolymer Acetal POM Sheet

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 100tons/month |

| Supply Ability: | 100tons/month |

| Payment Type: | T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDP,DDU |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou |

Product Description

Product Description

Ingredient Introduction

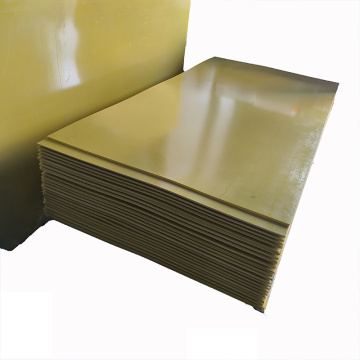

Basic resin: POM (polyoxymethylene) is divided into two types: homopolymer formaldehyde and copolymer formaldehyde.

Homoformaldehyde: It is polymerized from high-purity formaldehyde, with a regular molecular chain structure and a crystallinity of up to 75% -85%. It has better mechanical strength, rigidity, and thermal deformation temperature.

Co formaldehyde: synthesized by copolymerizing trimeric formaldehyde with cyclic ether, with slightly lower crystallinity (70% -75%), but better thermal stability and chemical corrosion resistance.

Additives: Lubricants (such as PTFE, silicone oil), antioxidants, UV stabilizers, etc. are often added to improve processing performance or weather resistance.

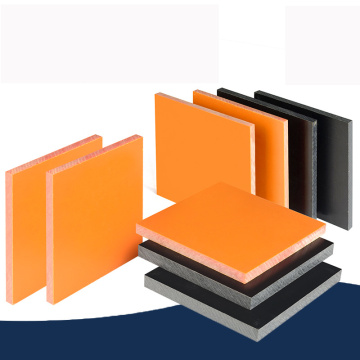

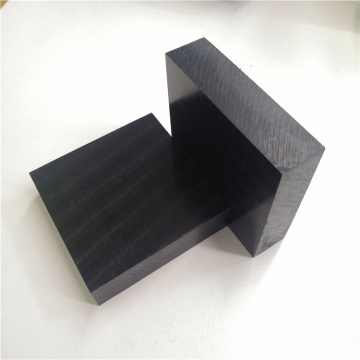

Modified reinforcement: can be filled with glass fiber (to improve strength and dimensional stability), carbon fiber (wear resistance), or added with conductive/anti-static materials (such as carbon black).

Performance characteristics

Mechanical properties:

High strength, high rigidity, high hardness, mechanical properties close to metal (specific strength up to 50.5MPa).

Excellent wear resistance and self-lubrication, low friction coefficient (0.21), suitable for sliding parts.

Outstanding fatigue resistance, fatigue strength still reaches 35MPa after 10⁷ alternating loads.

Thermal properties:

Wide long-term use temperature range (-40℃ to 100℃), homopolyformaldehyde heat deformation temperature is higher (172℃).

Chemical properties:

Oil-resistant and organic solvent-resistant, but sensitive to strong acids and phenols.

Product selling point

Metal replacement: lightweight, corrosion-resistant, can replace zinc, aluminum, etc. to manufacture gears, bearings and other parts, reducing costs.

Self-lubricating: no need for additional lubricants, reducing maintenance requirements, suitable for precision machinery

Application areas

Machinery manufacturing:

Precision gears, bearings, guide rails, mold inserts, using their wear resistance and dimensional stability.

Automotive industry:

Fuel system components (such as oil pump impellers), door locks, window adjustment gears, etc.

Electronic appliances:

Insulation parts, connectors, switch housings, relying on their electrical insulation and high temperature resistance.

Medical equipment and food machinery:

Parts that meet food contact requirements (such as food packaging equipment parts) and wear-resistant medical equipment components.

Others: Emerging fields such as construction equipment, drone parts, 5G equipment, etc.

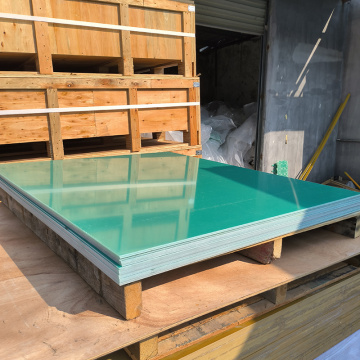

POM Sheet: Suitable for high-strength, wear-resistant, and temperature-resistant scenarios (such as mechanical transmission parts), but strong acid and ultraviolet environments must be avoided.

PP Sheet: Lightweight, chemically resistant, suitable for food packaging and low-temperature modification applications, but attention should be paid to low-temperature brittleness.

PE Sheet: Best cold resistance, suitable for low-temperature containers and flexible packaging, but low heat resistance and mechanical strength

Related Keywords

Related Keywords