Plastic Injection Mould Design Auto Car Parts Light Mould for Nissan Parts

-

USD2590≥1 Set/Sets

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 25 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | T/T |

|---|---|

| Incoterm: | FOB |

| Transportation: | Ocean |

Description:

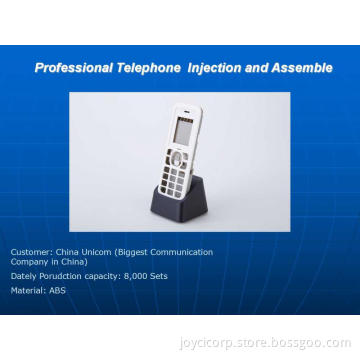

We are indulged in offering our client an excellent quality range of Auto Car component Mould, and Automotive Lights, which is available in NISSAN,TOYOTA,HONDA,BMW etc. We are widely marketing of our moulds in Europe and the biggest supplier for SSL Company in US. These Car Moulds are made from very high-quality raw material which ensures high durability and stability at its user end. Additionally, the different sizes with perfect designs are easily available in the market. Our Moulds are acceptable at industrial affordable price.

Service:

1. After receiving customer`s 2D/3D drawing, our engineers will evaluate and design part mould for clients.

2. Rapidly prototype mold is available

3. Specialized engineers work for order track and sales follow up, they are always ready for customer service.

Feature:

• Optimum finish

• Precise dimension

• Durability

• Negligible maintenance

Our Company:

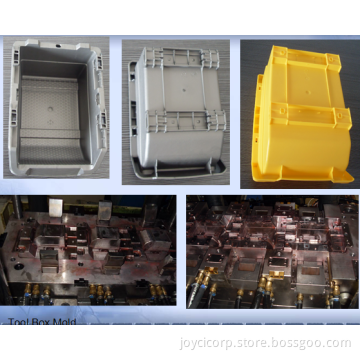

Established in 1995 and located in the mould manufacturing base of ShenZhen-BuJi Town, CREATIVE INNOVATIVE CO., LTD is a big-scale professional mould enterprise, who engages to design and manufacture moulds. With our continuous development, we own more than 45 sets of various advanced numerical controlling machines, such as CNC machines, EDM machines, Wire-cut machines etc. We have 20,000 square meters factory area, 140 experienced toolmakers and our annual productivity reaches to 500 sets of moulds, and over 80% moulds are exported to Europe, American etc all over the world.

There are 2 major branches of our factory-(1) the precision mould manufacturing center and (2) the big-size mould manufacturing center. Our excellent and well-experienced designers and engineers use the most advanced software i.e. CAD/CAE/CAM, helping us to produce the best molds accurately and rapidly. We also have 3D measurement Machines and Laser Scanner in our Quality Control Department which helps us ensure the best quality, reliability and consistency of our moulds.

We also have 20 sets injection machine from 80 ton-350 ton, and do all kindly plastic production for customer. we also have No-Dust plant, silk-screen plant and 3,000 square meters assemble area.

Related Keywords