Stainless Steel Parts CNC Services

- Min. Order:

- 1 Bag/Bags

- Min. Order:

- 1 Bag/Bags

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 2600/Month |

|---|---|

| Transportation: | Ocean,Land,Air |

Austenitic stainless steel parts refer to stainless steel parts with austenite structure at normal temperature. Such steel parts in addition to oxidation resistance acid medium corrosion, if contains Mo, Cu and other elements, but also can resistance to sulfuric acid, phosphoric acid and formic acid, acetic acid, urea and other corrosion. If the carbon content of such steel parts below 0.03% or containing Ti, Ni, can significantly improve its resistance to intergranular corrosion. High silicon austenitic stainless steel parts have good corrosion resistance to concentrated nitric acid. As austenitic stainless steel parts with a comprehensive and good overall performance, in all walks of life to obtain a wide range of applications.

Buildre Group Co., Ltd is a professional manufacturer of CNC and CNC Machining Services and Molding Services for OEM and ODM parts. And through the ISO 9001: 2008 quality certification system, the production base is located in Shenzhen bright. CNC machining plant covers an area of over 2,600 square meters, the main production of CNC machining parts for medical, automotive, communications, electrical, electronics and other industries. More than 46 CNC machining centers and CNC lathes for your service.

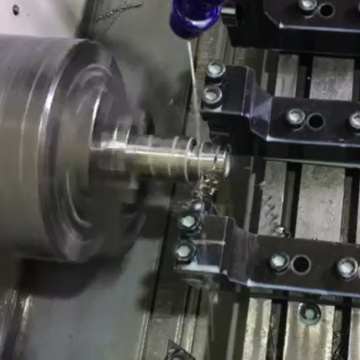

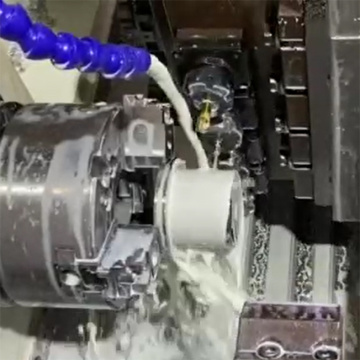

We offer industry-leading custom CNC turning and milling. Our precision parts serve medical, communications, aerospace, drone, and robots. Providing the best CNC turning and CNC horizontal / vertical milling. Our extensive range of state-of-the-art CNC lathes and CNC Turning machines meet the tolerances of ± 0.01mm.

|

Business content |

CNC miliing, CNC turning |

|

Machining Processes |

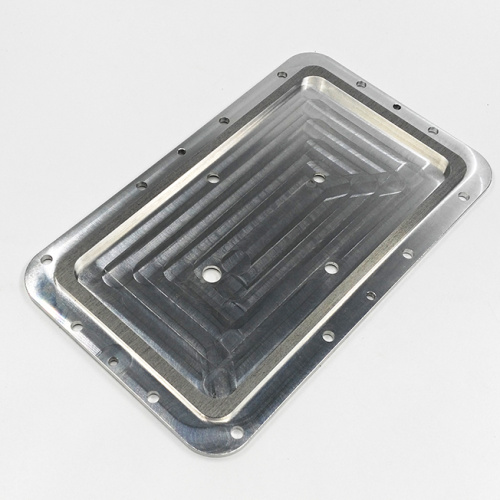

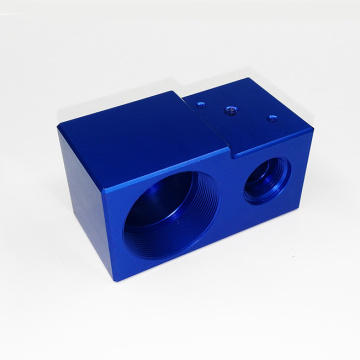

CNC Milling, CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threasing, Tapping, Drilling, Knurling |

|

Machining Metal |

Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM |

|

Parts Size |

Milling Parts ( MAX) : Length 1030mm,Width 800mm, Height 750mm. Turning Parts ( MAX) : Diamter 680mm,Length 750mm. |

|

Tolerance |

0.01mm |

|

Equipment Capabilities |

CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch |

|

Secondary Services of Machining Parts |

Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing |

|

Sample |

Samples are for free, sample time is 5 days. |

|

Delivery |

Delivery time is 3-4 week, depending on the degree of difficulty of machining parts |

|

file format |

Para-Solid 3D, PDF, IGES, STEP, SOLIDWORKS |

The perfect ISO9001: 2008 quality system certification to ensure product quality. The quality personnel perform dimensional measurements on each piece of CNC machined parts.Measuring instruments: Digital caliper, Micrometer Calipers, height gauge, Profile projecto. Measurable accuracy of 0.001mm. In order to improve the speed of inspection, the engineers designed sophisticated auxiliary fixture. We provide dimensional reports of machined parts.

CNC Machining can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Related Keywords