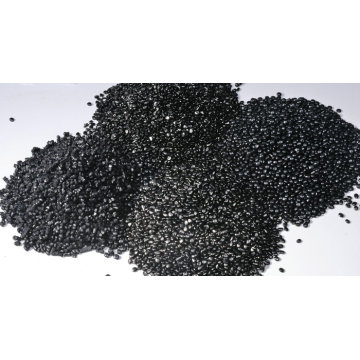

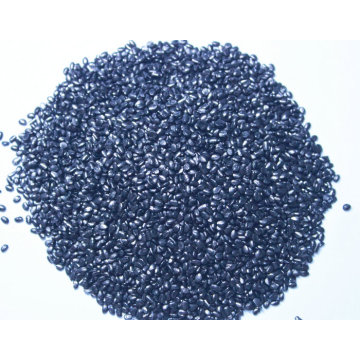

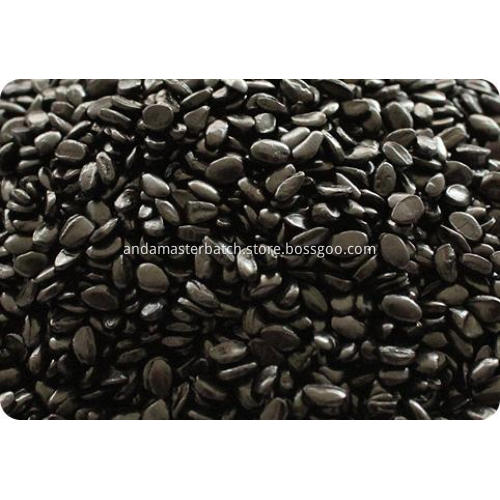

50% Carbon Black High Concentration Black Masterbatch

- Payment Type:

- L/C, T/T, D/P

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 5 Ton

- Min. Order:

- 5 Ton

- Delivery Time:

- 10 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500kg/Hour |

| Supply Ability: | 500ton/Month |

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | SGS |

| Transportation: | Ocean |

Description of 50% Carbon Balck Masterbatch 9014E

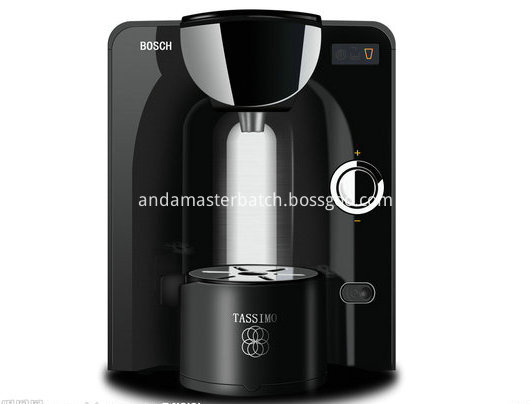

As the 5th generation of 9014 series, 9014E contents 50% the mixture of imported high pigment carbon black and local high quality carbon black. The 50% carbon Black Black Masterbatch 9014E is one of the mostly well sold high jetness injection black masterbatch.With excellet blackness and mirror effect end-products surface, the 50% Carbon Black Masterbatch 9014E are widely used for high-end injection plastic production, such TV frame, coffee hot, cell phone shee, hair-blower enclosure so on. The 50% Carbon Black Masterbatch 9014E is made of 100% Virgin powder polyethene carrier and high-qulaity carbon black, without any calcium carbonate filler, adding special chemical additives for lubricant and dispersion. The 50% Carbon Black Masterbatch is one food contact grade black masterbatch, complying with SGS testing and ROHS requirements, heavy metal free,no any odor smell, compatiable with ABS, PC, PS, Nylon, PPM, PPS all engineering materials. 50% Carbon Black Masterbatch 9014E has suitable disperiona abilties, its MFI is as high 18 gram/10 mintues 21.6kg &190 Cdegree.The 50% Carbon Black Masterbatch 9014E could be directly used for most thermal plastic hard resins injection , molding and compounding, pressure sheet.

Ingredients of 50% Carbon Black Masterbatch 9014E

Carbon Black Content=50%±1%

Carrier=Virgin Powder LLDPE

Carbon Black =Imported Pigment Carbon Black and China-made Carbon Black(ZY-1)

High Quality Virgin PE+PP Wax

Compatiabilities

The 48% Carbon Black Black Mastebatch 9014D is compatible with ABS, PC, PS, Nylon, PPM, PPS and all engineering materials.

Method of Usage

The 50% Carbon Black Black Masterbatch 9014D is suitable for direct addition and mixing with plastic resins in mixer,avoiding pollution and mal-scattering problems caused by pigment, no need pre-drying before production.

Recommended Dosage

1-3% subjected to the final products requirements.

Physical Properties

Density(24℃) : 1,120kg/m3

Melting Flow Index : 18g/10min(21.6kg/190℃)

Moisture Content : <0.15%

Packaging And Storage

The 50% Carbon Black Black Masterbatch 9014E is supplied in pellet form and packed in 25kg plastic or paper bags.It should be stored in a dry place.

ANAD MASTERBATCH-- COUMPOUNDING YOUR SUCCESS!

Related Keywords