Digital accessories injection processing

Your message must be between 20 to 2000 characters

Contact Now

"Computer accessories injection products

The company has 20 years of computer accessories injection products, the use of 100% injection of raw materials production, never use the second use of materials, each bag of raw materials are involved in the project to follow the label. Strict implementation and development of injection molding process to ensure that the first and production to maintain consistency. Injection molding workshop in the injection of all the quality of production in Germany Bayer, the United States Huntsman, Taiwan Chi Mei, Sunrise and other internationally renowned brands of raw materials.

20 years, enterprises have been to follow the high efficiency of the work, the purpose of high-quality services to provide customers with a complete set of injection molding manufacturing solutions. Decorative products injection molding professional technical team, precision supporting the production equipment, with precision two-color forming machine 7, single-color electric precision forming machine 50, advanced management mode, to win the support of many large customers and trust, such as Samsung, Foxconn , BYD, Logitech, SF Express, Whirlpool, Yuanwang Valley and so on. The company gradually implemented ISO9001: GB2008 quality management system, and employ more than experienced practitioners of quality management personnel; from the feed, production, shipping are controlled, can be investigated, traceable

20 years, enterprises have been to follow the high efficiency of the work, the purpose of high-quality services to provide customers with a complete set of injection molding manufacturing solutions. Decorative products injection molding professional technical team, precision supporting the production equipment, with precision two-color forming machine 7, single-color electric precision forming machine 50, advanced management mode, to win the support of many large customers and trust, such as Samsung, Foxconn , BYD, Logitech, SF Express, Whirlpool, Yuanwang Valley and so on.

The company in good faith, sound, efficient and innovative spirit of enterprise, with full participation, unity Pinbo, quality products, customer satisfaction, continuous improvement, the pursuit of excellence in quality policy, the spirit of ""credibility first, quality first, One, cheap first ""business philosophy, and sincerely look forward to working with colleagues at home and abroad work together to create brilliant! Injection Department with a variety of domestic and foreign brands of single-color injection molding machine, the products involved in beauty equipment, smart wear, auto parts, communications equipment, home appliances, medical equipment, photographic equipment and other fields. Manufacturing industry experience, sophisticated mold technology team, advanced mold manufacturing and testing equipment; have a variety of tonnage precision injection molding machine, a comprehensive through the ""ISO9001: 2008 version of"" quality management system certification, the general taxpayer qualification, import and export trade rights; Products are exported to Europe and the United States, Asia Pacific and other countries and regions, is your quality, delivery, service, the best price unit choice!

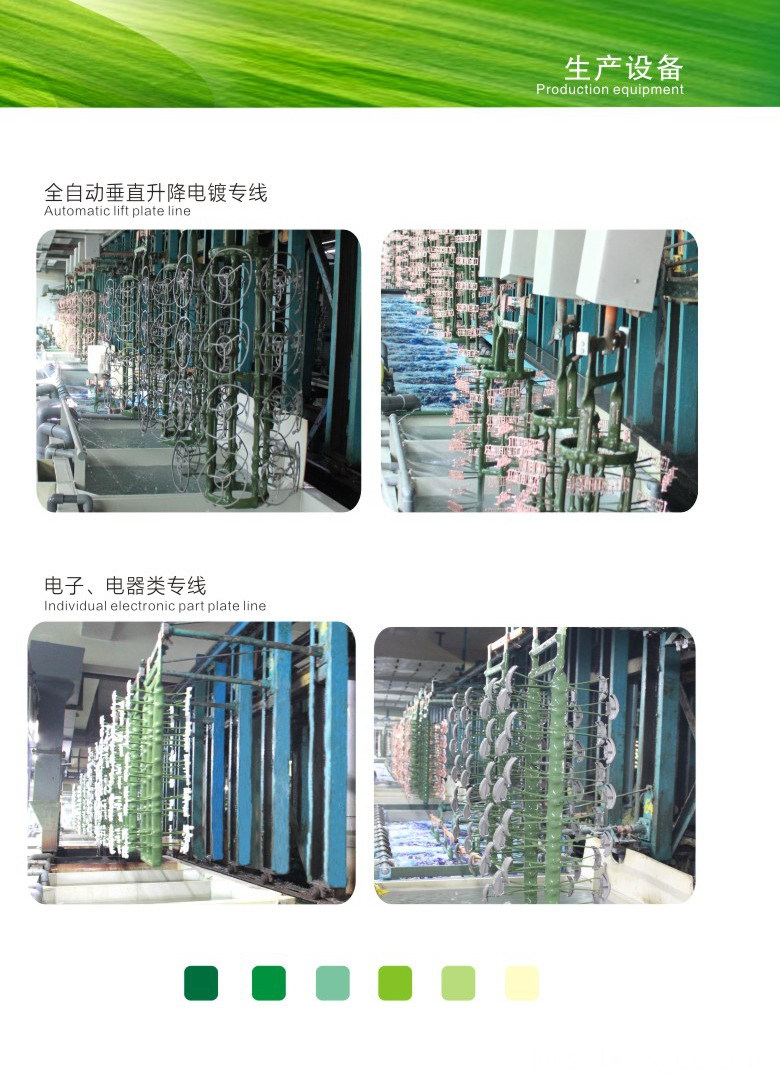

Enterprises have always attached importance to precision manufacturing, the existing Haitian two-color injection molding machine 10, 5 high-speed machine, a total of 66 other injection molding machine.

Mold processing using the European imports Mickland processing center, summer Mirror mirror spark machine, Hexagon four yuan and other mold manufacturing equipment for many well-known domestic and foreign enterprises to provide high-precision plastic pieces!

Jinyuan Kang injection molding workshop is specialized in dual materials, two-color molding and mold manufacturing high-tech enterprises. With the development of industrial technology, product appearance, function, structure and other aspects of the continuous improvement of quality, monochrome products have been unable to meet. I set the Secretary for professional two-color mold design and manufacturing as one, improve the quality assurance and service system to meet customer needs.

In the management of the full realization of the modern mode of production and management system, adopted the ISO9001: ISO / IEC 14001: 2004 / IECQ QC080000: 2005 / TS16949 international system certification.

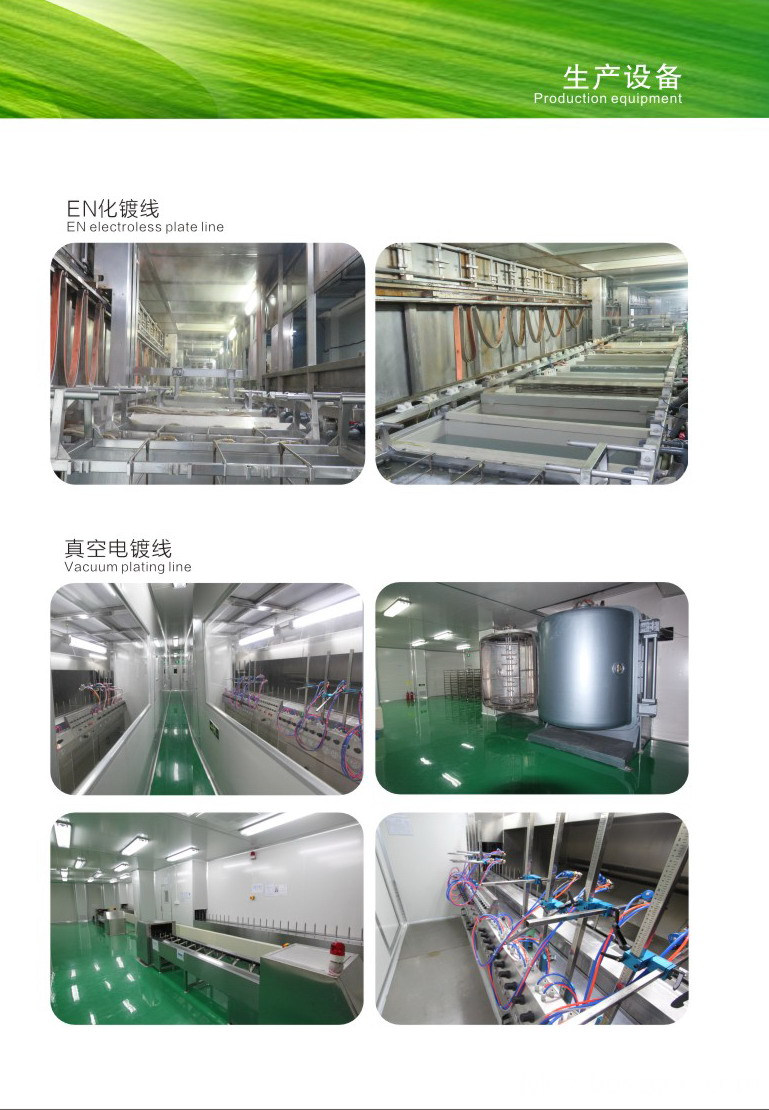

Shenzhen Jinyuan Kang Industrial Co., Ltd. was established in 1999, the main research and development, design, manufacture all kinds of plastic metal molds, auto parts mold injection molding products, external injection molding, spraying, silk screen, printing, electroplating, finished assembly and other train services. Company is located in Shenzhen Pingshan New District, the environment elegant, convenient transportation, financial strength, well-equipped, covers an area of 40,000 square meters, more than 800 employees.

Our 20 years, our business scope covers a wide range of consumer electronics, industrial handheld equipment shell mold, injection molding, spraying, silk screen, assembly and other full line processing services, at the same time, our precision mold manufacturing also designed cars, medical, smart home High-end industry, in addition, we also provide OEM and ODM solutions to customers around the world, dedicated to customer service around the world!

Related Keywords