Injection Mould Inserts Making

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 14 Days

- Transportation:

- Air

- Port:

- Shenzhen, Hongkong, Guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Made in China |

|---|---|

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001 |

| HS Code: | 84807190 |

| Transportation: | Air |

| Port: | Shenzhen,Hongkong,Guangzhou |

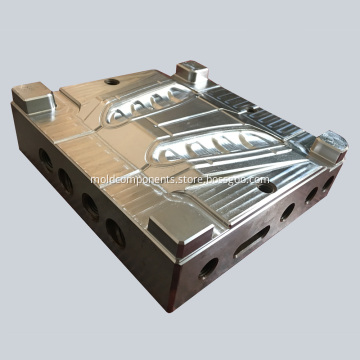

Injection Mould Inserts Making

Hongzhun technology is a professional CNC Machining company, specializing in the Prototype Machined Parts for more than 10 years, has accumulated a lot of practical experience. Especially for the Mold Insert and Machine Precision Components. In Injection Molding, has a complete process design mechanical operation of the site guidance. According to the practical operation experience, we can find out a set of mould and mechanical parts which are suitable for the production of copper and aluminum products. Have a complete and scientific quality management system. Hongzhun in good faith, strength and quality of products recognized by the industry. If you are interest our service(Machining Small Metal Parts) and want to try this way to your new project, feel free contact us directly, we will always do our best to support you.

Description:

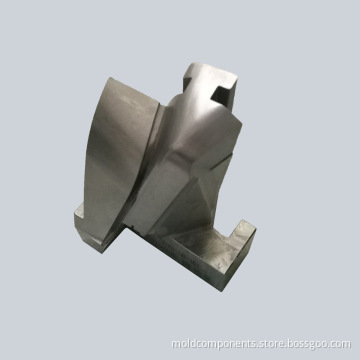

- Process tolerance: +/-0.01mm

- Manufacturing Lead time: 10 days

- Delivery lead time: 3 days

- Size: 35X70X80mm

- Material: 1.2311

- Hardness: 290-330 HB

- ISO 9001 certified

- Mold Tool Slider for Injection Mold

- HS code: 84807190

Advantage:

- Show your customers and investors a model of your product

- Demonstrate the appearance, dimensions and features of your product

- Test your design for its suitability

- Save time and money by identifying and reducing design flaws

- Improve and streamline the production process

- Reduce your work load when the time comes to manufacture

- Create multiple versions with different colors, surface textures and finishing processes

Why choose us?

- Mature technology with precision equipment we use. Our parts will prefectly suit your needs, can be assembled immediately without fitting.

- High quality insurance. All parts be fully inspected in each stage of process. Inspection report will be provide with everything correct and acccurate.

- Fastest deliver time, as soon as 15 days tooling time +3 days deliver time for whole set of mold parts.

Company Image:

At HZ, we use Hi-speed CNC machine center, Sodick slow-feeding-wire-cut, Sodick mirror EDM and CMM machine checking every process to provide accuracy and precision when making your CNC Machining parts & Mold Components. Our professional and aspiring team of engineers and technicians work in a clean and tidy environment use the advanced equipment, to turn your concepts into reality quickly, accurately and at a great price. You design it and we will make it.

Office and Design Department

High-speed CNC machine

Precision EDM and Wire-EDM

Inspection Department

Related Keywords