Precision Plastic Injection Mold

- Payment Type:

- T/T

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 42 Days

- Transportation:

- Ocean

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000K shots |

| Supply Ability: | 30 sets per month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Certificate: | ISO 9001:2008 |

| HS Code: | 8480719090 |

| Transportation: | Ocean |

| Port: | Shenzhen |

With our custom injection molding capabilities, we can produce parts that range in size from 10 grams to 2 pounds in weight and up to 150 square inches in surface area. Low volume production runs as few as 100 parts can be handled too. Our molding services are offered in a wide variety of engineering and commodity materials, including ABS (Acrylonitrile Butadiene Styrene), Nylon (Polyamide), PC (Polycarbonate), and several other materials.

As part of our plastic injection molding services, we provide insert molding and over molding capabilities as well. Furthermore, we offer molding services for parts made from high strength composites that can be used to replace metal components. Ultrasonic welding, heat staking, pad printing, thread tapping, and assembly are some value added services that we provide.

| Project Information | ||

| Product Description | Part Name | Plastic Injection Mould |

| Part Material | PC | |

| Part Size(mm) | 450*450*400 | |

| Mould Description | Cavity Insert Material |

2343HRC48-52 |

| Core Insert Material |

2343HRC48-52 |

|

| Slider Insert Material |

2343HRC48-52 |

|

| Mould Cavities | 1 | |

| Mold parts Standard |

Hasco |

|

| Mould Life Time (Shots) | 500,000 | |

| Mould Type | Formal mold | |

| Runner Description | Cold runner | |

| Injection Gate Type | Tip gate | |

| Ejection System | Ejector pin | |

| Slide Qty. | 1 | |

| Lifter Qty. | 0 | |

| Injection moulding machine | 250T |

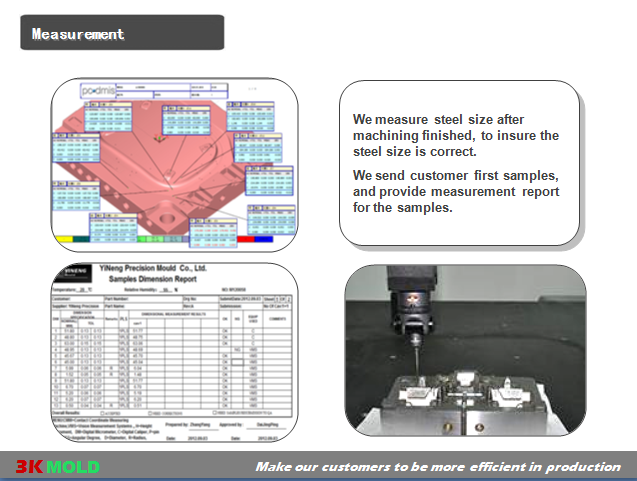

Precision plastic injection mold 3K Mold is ISO-9001: 2008 certified. We use formal quality systems to manage the overall quality process and use precision measurement facilities by our well-trained team. All tooling and parts produced at our facility are constantly monitored by our Quality Assurance Department to meet your specifications.

Quality control Center:

3K team committed to meet customer quality and delivery request. The main quality control process as following:

Incoming quality control (IQC)

In process quality control (IPQC)

Quality assurance (QA)

Quality management flow:

1. Mold base inspection

2. Steel inspection

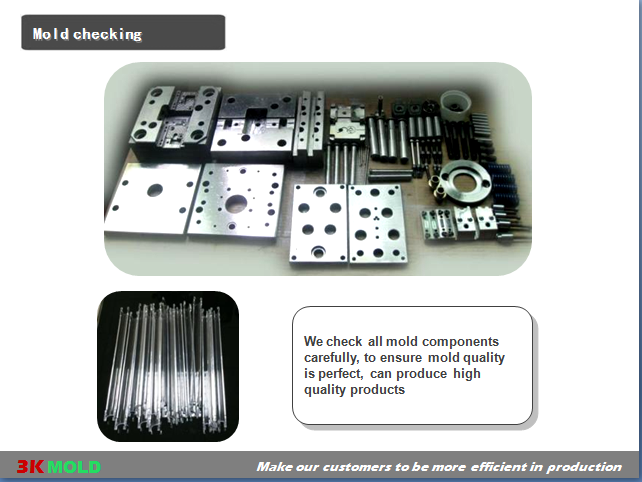

3. Mold component inspection

4. Electrodes inspection

5. Mold checking before assembly

6. (FAI, CPK) First Article dimension report

7. Mold checking before delivery

Related Keywords