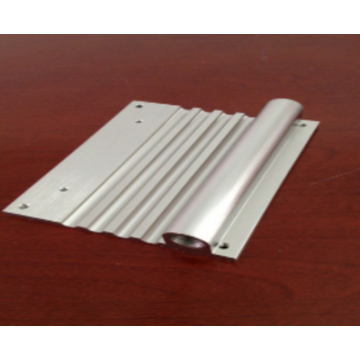

Shot gyro spray anodizing anodization

- Payment Type:

- T/T

- Min. Order:

- 10 Bag/Bags

- Min. Order:

- 10 Bag/Bags

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

- Port:

- SHENZHEN, Guangzhou, Shanghai

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | China |

| Supply Ability: | good |

| Payment Type: | T/T |

| Transportation: | Ocean,Land,Air |

| Port: | SHENZHEN,Guangzhou,Shanghai |

Product Description

Product Description

The practical advantage of the so-called "anodic" coatings on aluminum alloys to increase the adhesion of paint [8]1 has been well established and accepted for a number of years. Coatings of this kind are produced electrolytically by making the specimen the anode in a suitable electrolytic bath. The outstanding coating used for the above purpose for a number of years is that produced in an electrolyte of chromic acid. The only concentration of chromic acid used previous to the present investigation was that recommended by Bengough [3] in 1926. In this method a 3-percent (0.3 M) chromic acid solution was used for the electrolyte and a definite empirical voltage cycle was specified, a requirement that made the method an intermittent process. This requirement was a decided limitation in mass production and has been cited by proponents of other methods as the outstanding objection to the use of the chromic acid method. This limitation, coupled with the relatively early "break-down" of the bath, and the very narrow "anodizing" range of voltage and temperature, prompted the study here reported. The purpose of the investigation was to improve the method, both with respect to the stability of the solution and to the technique of the anodizing process.

Related Keywords

Related Keywords