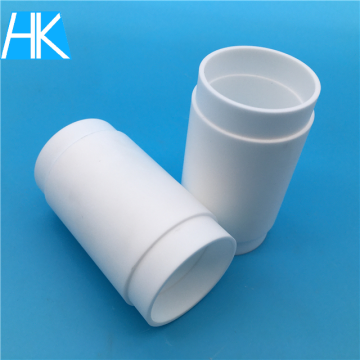

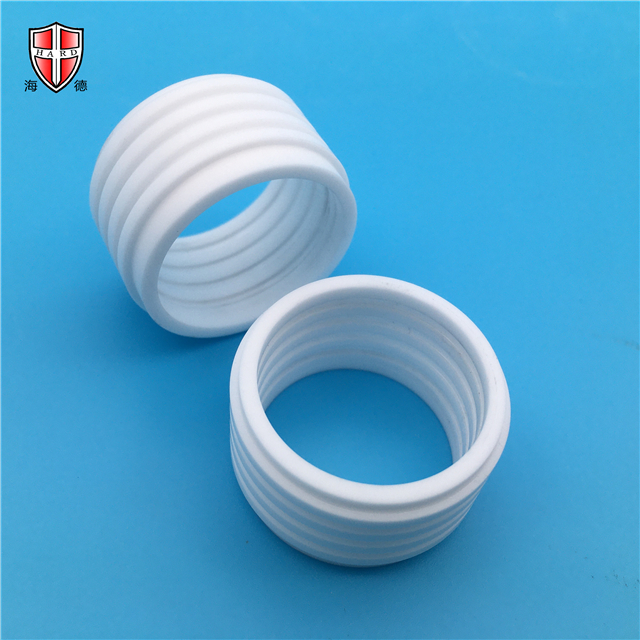

machinable beryllia BeO ceramic threaded pipe sleeve bushing

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

machinable beryllia BeO ceramic threaded pipe sleeve bushing

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Shenzhen Hard Precision Ceramic Co., Ltd. is the earliest professional manufacturer of beryllium oxide ceramics in China, with a production history of more than 40 years; it is the only designated manufacturer of beryllium oxide ceramics for military use in the country, and its production capacity is In recent years, the basic production technology of beryllium oxide ceramics has been introduced from the United States. After joint research with the University of Electronic Science and Technology, through digestion and absorption for localization, a set of independent innovation and independent intellectual property rights has been formed. Production technology of beryllium oxide ceramics. At present, the technology has been applied to the development of a number of national "high-tech projects" supporting projects. Some performance indexes of the beryllium oxide ceramic products produced are close to the American standards, and some indexes have exceeded the American standards. The development of beryllium oxide ceramics abroad began in the 1930s, but its rapid development stage was from the late 1950s to the late 1970s. The main products are pure beryllium metal, beryllium aluminum alloy, beryllium copper alloy, high-quality BeO ceramic powder, various 99.5% BeO ceramic products, and BeO ceramic packaging shells. Its products are widely used in lasers for skin cosmetic surgery, cataract removal, kidney stone crushing and painless surgery, as well as military defense systems. The company has offices in Japan and other countries and regions.

American Beryllium Oxide Co., Ltd. was founded in 1956 and is a pioneer in the research and development of high-purity beryllium oxide ceramics. In the early 1960s, standard and general shape BeO ceramic products and dry pressing, extrusion and sintering technology were developed to meet the requirements of various applications. In the late 1960s and early 1970s, the company was equipped with precision grinding equipment, and at the same time equipped and adopted drilling, metallization, polishing, slicing and other equipment and technologies. Beryllium oxide ceramics is different from other electronic ceramics. So far, its high thermal conductivity and low loss characteristics are difficult to replace by other materials. On the one hand, due to the large needs of many scientific and technological fields, on the other hand, because of the toxicity of beryllium oxide, protective measures Due to the strict and difficult nature, there are few factories in the world that can produce safely, and some developed industrial countries abroad (such as Japan) rely entirely on imports. The United States is the country with the largest output of BeO ceramics, the highest production technology, and the best product performance in the world, followed by the United Kingdom and Kazakhstan.

Because BeO ceramic materials play an irreplaceable role in the application of aviation, aerospace and military equipment, the demand for BeO is increasing year by year. The output of BeO in the United States at the end of the 1990s was 3 to 5 times that of the end of the 1980s, and it is currently increasing at a rate of 8 to 12%, and its output has reached more than 200 tons. The US Defense Electronics Supply Center proposed to the industry a plan to develop high-performance BeO ceramic materials several years ago. And progress has been made. In the material list of the supply center, the position of beryllium oxide is gradually improving. In the next few years, beryllium oxide will be the material of choice for military high-power MCM (multi-chip components).

Beryllium oxide ceramics are ceramics with beryllium oxide as the main component. Mainly used as materials for large-scale integrated circuit substrates, high-power gas laser tubes, heat sink shells of transistors, microwave output windows and neutron moderators. Beryllium oxide ceramics have the characteristics of high thermal conductivity, high melting point, high insulation, high chemical and thermal stability, low dielectric constant, low dielectric loss and good process adaptability. It is used in special metallurgy, vacuum electronic technology, nuclear technology, Microelectronics and optoelectronics technology are widely used. Especially in high-power semiconductor devices, integrated circuits, microwave electric vacuum devices and nuclear reactors, BeO is the mainstream ceramic material for preparing high thermal conductivity components.

BeO ceramic products are also a refractory material. BeO ceramic crucible can be used to melt rare metals and precious metals, especially in the occasions requiring high-purity metals or alloys. The working temperature of the crucible can reach 2000°C. Due to its high melting temperature (approximately 2550°C), high chemical stability (alkali resistance), thermal stability and purity, BeO ceramics can also be used to melt uranium and plutonium. In addition, these crucibles have been successfully used to make standard samples of silver, gold and platinum. BeO's high degree of "transparency" to electromagnetic radiation allows the use of induction heating to smelt the metal samples in it.

Data Sheet↓

| Beryllia Ceramic Properties | ||

| Item | Unit | Typical Values |

| Physical Properties | ||

| Color | White | |

| Density | g/cm3 | 2.85 |

| Grain Size | um | 10—20 |

| Gas permeability | cc/sec He | 10-8 |

| Water Absorption | % | 0 |

| Mechanical Properties | ||

| Rockwell 45N | 60 | |

| Flexural Strength(20°C) | Mpa | 200 |

| Tensile Strength | Mpa | 152 |

| Modulus of Elasticity | Gpa | 345 |

| Poisson's Ratio | 0.26 | |

| Fracture Toughness(20°C) | MPam1/2 | 3.5 |

| Thermal Properties | ||

| Thermal Conductivity(100°C) | W(m.K) | 200 |

| Thermal Expansion Coefficient | 10-6/°C | 7.0-8.5 |

| Specific Heat | cal/g°C | 0.25 |

| Electronic Properties | ||

| Dielectric Strength | KV/mm | ≥30 |

| AC Dielectric Strength | V/mil (6.35mm) | 230 |

| Dielectric Constant | 1 MHz (at RT) | 6.6±0.1 |

| Dielectric Constant | 10 GHz (at RT) | 6.9±0.1 |

| Dielectric Loss Angle | 1 MHz (at RT) | ≤4*10-4 |

| Volume Resistivity(25°C) | Ω.cm | ≥1014 |

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords