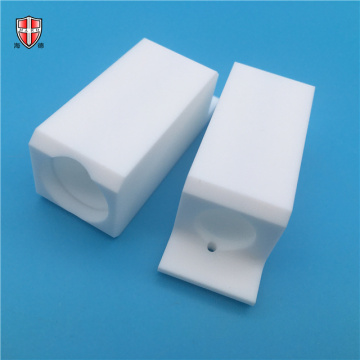

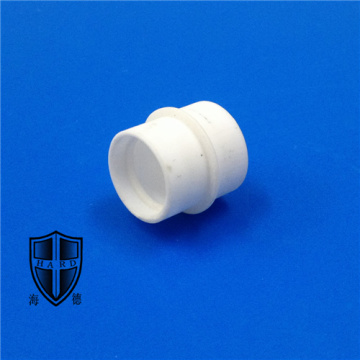

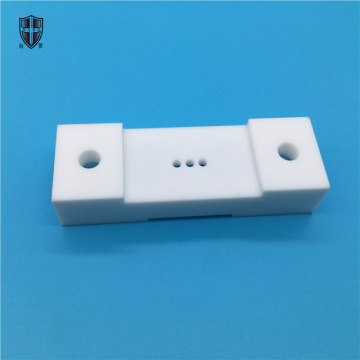

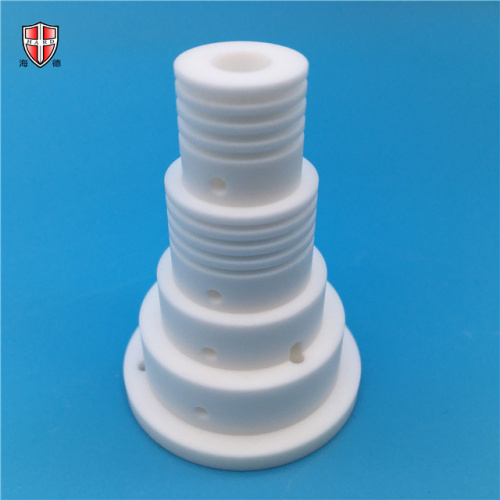

microcrystalline ceramic machinable structural parts

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

custom insulator microcrystalline ceramic machinable structural parts

Reputation depends on quality, quality comes from Hard!

Macor Glass Machinable Glass Ceramic:

Silicone plastics in the form of polysiloxane structure are widely used in electronics and electrical technology. Silicone laminated plastics are mostly reinforced with glass cloth; silicone molded plastics are mostly filled with glass fiber and asbestos, which are used to manufacture parts that are resistant to high temperature, high frequency or submersible motors, electrical appliances, and electronic equipment. This type of plastic is characterized by its low dielectric constant and tgδ value, and is less affected by frequency. It is used in electrical and electronic industries to resist corona and arcs. Even if the discharge causes decomposition, the product is silicon dioxide instead of conductive carbon black. . This type of material has outstanding heat resistance and can be used continuously at 250°C. The main disadvantages of polysiloxane are low mechanical strength, low adhesiveness and poor oil resistance. Many modified silicone polymers have been developed, such as polyester modified silicone plastics and have been applied in electrical technology. Some plastics are both thermoplastic and thermosetting plastics. For example, polyvinyl chloride is generally a thermoplastic. Japan has developed a new type of liquid polyvinyl chloride that is thermoset and has a molding temperature of 60 to 140°C. A plastic called Lundex in the United States has both thermoplastic processing Features, and physical properties of thermosetting plastics. Hydrocarbon plastics. It is a non-polar plastic and has crystalline and non-crystalline properties. Crystalline hydrocarbon plastics include polyethylene, polypropylene, etc., and non-crystalline hydrocarbon plastics include polystyrene, etc. Vinyl plastics containing polar genes. Except for fluoroplastics, most of them are non-crystalline transparent bodies, including polyvinyl chloride, polytetrafluoroethylene, polyvinyl acetate, etc. Most vinyl monomers can be polymerized with radical catalysts. Engineering thermoplastics. Mainly include polyoxymethylene, polyamide, polycarbonate, ABS, polyphenylene ether, polyethylene terephthalate, polysulfone, polyethersulfone, polyimide, polyphenylene sulfide, etc. Polytetrafluoroethylene. Modified polypropylene, etc. are also included in this range. Thermoplastic cellulose plastics. Mainly include cellulose acetate, cellulose acetate butyrate, celluloid, cellophane, etc.

properties:

Good insulativity, high temperature(800°), good machinable property, can be made of rod and plate in short time.

Data Sheet↓

Color: WhiteDensity: 2.6g/cm3

Gas permeability: 0

Water Absorption: 0

Rockwell Hardness(45N): 40R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 108Mpa

Compressive Strength(20°C): 488Mpa

Modulus of Elasticity(25°C): 65Gpa

Thermal Conductivity(25°C):1.71W(m.K)

Thermal Expansion Coefficient: 7.2 10-6/°C

Thermal Shock Resistance: 200 △T°C

Maximum Use Temperature: 800°C

Dielectric Strength: >30 KV/mm

Volume Resistivity(20°C): >10(16)Ω.cm

Application industry:

Machinery, electronic, limitary, aerospace etc.

Specific application:

Machined equipment high temperature insulated parts, electronic equipment high temperature insulated parts.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords