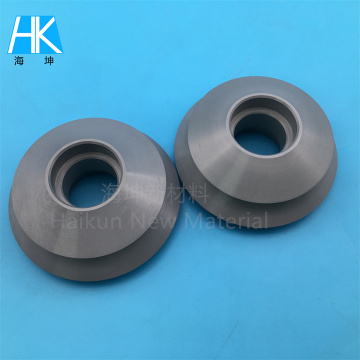

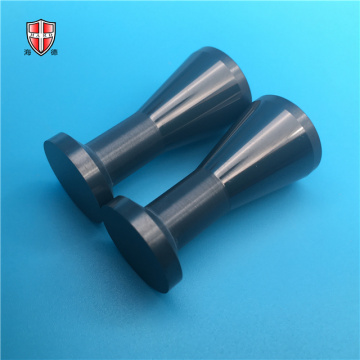

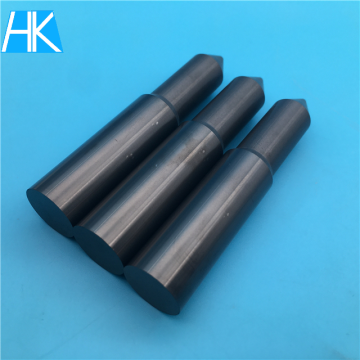

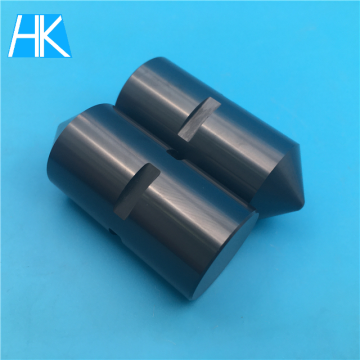

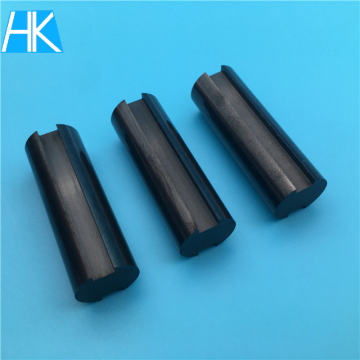

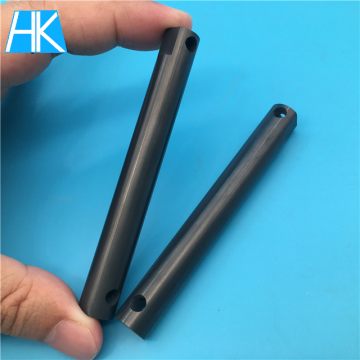

precision tolerance silicon nitride plunger piston ceramic

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

precision tolerance silicon nitride plunger piston ceramic manufacturer

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramics:

The general development trend of China's plastic products industry is: agricultural plastics (including agricultural mulch, water-saving agricultural equipment and geosynthetics) still occupy an important position and will be further developed, Our silicon nitride ceramic plunger and ceramic plunger are expected to improve the efficiency and reliability of agricultural machinery and contribute to the sustainable development of the industry; packaging materials and plastic building materials will be the rapid growth of the plastics industry Main areas: high-tech, high value-added engineering plastic products and composite materials, the production and application fields will continue to expand with the development of the market economy; the production of pipes, profiles, calendered products, biaxially oriented materials, films, etc. Gradually develop in the direction of economic scale; in order to protect the ozone layer, foam plastic production will undergo fluorine-free technological transformation; in order to reduce environmental pollution, the recycling of waste plastics and the research and development of degradable plastics will be strengthened; in order to develop varieties of plastic products and improve the grade, plastic The development and production of machinery and molds will be valued. Plastic molding processing refers to the process of making final plastic products from polymers manufactured by synthetic resin manufacturers. Processing methods (commonly referred to as one-time plastic processing) include compression molding (compression molding), extrusion molding (extrusion molding), injection molding (injection molding), blow molding (hollow molding), calendering, etc. After the sheet is heated to a certain temperature by a blister machine, the plastic sheet is adsorbed on the surface of the model through a vacuum pump to generate negative pressure, and the plastic sheet is cooled and shaped to be transformed into a blister or blister of different shapes. Compression molding is also called compression molding or compression molding. Compression molding is mainly used for the molding of thermosetting plastics such as phenolic resin, urea-formaldehyde resin, and unsaturated polyester resin.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

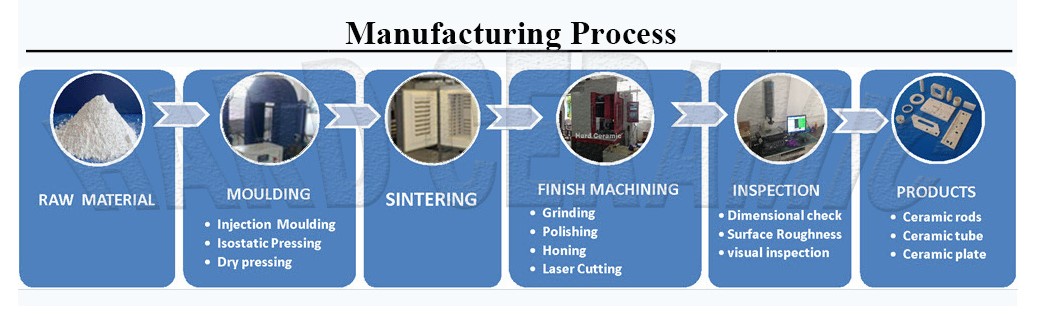

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords