High Temperature Resist Silicon Nitride Ceramic Roller Rod

-

$10.00≥10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shenzhen, Guangzhou, Dongguan

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 10000pcs/month |

| Supply Ability: | 10000pcs/month |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,CPT,Express Delivery |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shenzhen,Guangzhou,Dongguan |

Product Description

Product Description

Silicon Nitride (Si3N4) / CeramaSil-N™

Silicon nitride (Si3N4) has the most comprehensive combination of mechanical, thermal and electrical properties of any advanced ceramic material. It is a high-performance advanced ceramic that is extremely hard and has excellent thermal shock and impact resistance. It exceeds the high-temperature resistance of most metals and has excellent creep and oxidation resistance. In addition, the low thermal conductivity and high wear resistance of silicon nitride make it an excellent material for withstanding the harshest conditions in the most demanding industrial applications. Silicon nitride is an excellent choice when high temperatures and high load capacity are required.

Silicon Nitride Ceramic Properties

* High strength over a wide temperature range

* High fracture toughness

* High hardness

* Outstanding wear resistance, both impingement and frictional modes

* Good thermal shock resistance

* Good chemical resistance

Application Uses

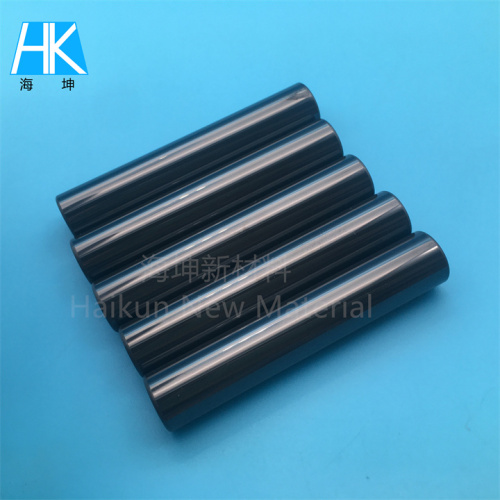

* Rotating bearing balls and rollers

* Cutting tools

* Engine moving parts — valves, turbocharger rotors

* Engine wear parts — cam followers, tappet shims

* Turbine blades, vanes, buckets

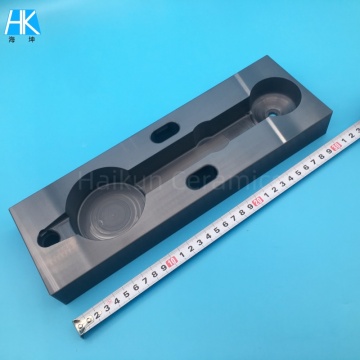

* Metal tube forming rolls and dies

* Precision shafts and axles in high wear environments

* Weld positioners

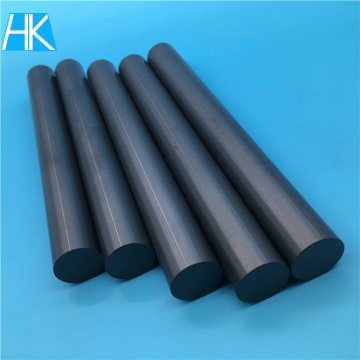

Dongguan Haikun New Material Co.,ltd manufacturing Silicon Nitride (Si3N4) rods have high mechanical strength, wear resistance, and chemical inertness. They are often used in high-temperature applications due to their high melting point and thermal stability.

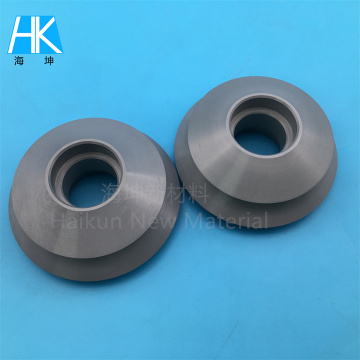

Products Show

Ceramic CNC Machining Manufacturing Process

Why Choice us

1.17 years of professional production industrial ceramics factory

2. High quality products with low price

3. High precision parts with lowest tolerance

4. Show time for production

5. Has a group of experienced, professional and efficient R&D team

6. Has a good reputation in China and abroad.

7. MOQ is not limited, small quantity is welcome.

8. Vigorous team and good after-sales service

2. High quality products with low price

3. High precision parts with lowest tolerance

4. Show time for production

5. Has a group of experienced, professional and efficient R&D team

6. Has a good reputation in China and abroad.

7. MOQ is not limited, small quantity is welcome.

8. Vigorous team and good after-sales service

Related Keywords

Related Keywords

You May Also Like

You May Also Like