corrosion resistant Si3N4 ceramic machinery parts

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

corrosion resistant Si3N4 ceramic machinery parts

Reputation depends on quality, quality comes from Hard!

Silicon Nitride Ceramic:

High-temperature ceramic wear-resistant materials are widely used in power plants and steel smelters. The temperature of steel smelting mills is between 800 and 1200 degrees. Therefore, materials are required to withstand high temperatures and the requirements for wear resistance are very strict. Many manufacturers use refractory castables to solve the wear problem of this part, but the effect is not very satisfactory, because refractory castables have a very good effect on high temperature resistance, but the wear resistance will be seriously degraded after high temperature. High-temperature wear-resistant ceramic coating fills this gap. Its special high-temperature resistant glue can form a sintering reaction with the material during the sintering process. The compressive strength of the ceramic coating layer after sintering reaction can reach 161, and the flexural strength can reach 17.8. And can continue to play its role. Ceramic wear-resistant materials have high requirements for mixing and construction. The mixing time is about 15 minutes. The mixing time is closely related to its unique raw material configuration and special glue. The stirred high temperature and wear resistant ceramic coating is taken out from the mixer, transported to the construction site and poured onto a clean platform. Each time about 2 kg of material is taken out and applied to the welded tortoise shell net or V-shaped hook nail. Firmly smooth the compaction to ensure that the material can be firmly bonded to the surface of the steel plate or the tortoise shell, and then hammered with a hammer or rubber hammer to increase its density strength.

properties:

High hardness, high strength, wear resistance, corrosion resistance, high temperature(1200°), good thermal diffusivity, good thermal shock resistance(avoid the temperature changing rapidly), good insulativity, low density. The comprehensive properties are best in most of structure ceramic.

Data Sheet↓

Color: Black GreyDensity: >3.2g/cm3

Hardness: HRA90

Vickers Hardness (Hv50): >1550 HV0.5

Modulus of Elasticity: 290Gpa

Flexural Strength: >600Mpa

Compressive Strength: 2500Mpa

Modulus of Elasticity(25°C): 65Gpa

Fracture toughness:>6.0 Mpam1/2

Maximum Use Temperature: 1200°C

Thermal Conductivity:15-20 W(m.K)

Thermal Expansion Coefficient: >3.1 10-6/°C

Thermal Shock Resistance: 500 △T°C

Special Heat Capacity: 700 KJ/kg.K

Dielectric Strength: 1 KV/mm

Dielectric Constant: er

Volume Resistivity(20°C): 1.0*10(12)Ω.cm

Application industry:

Machinery, electronic, semiconductor, chemical, petroleum, smelt.

Specific application:

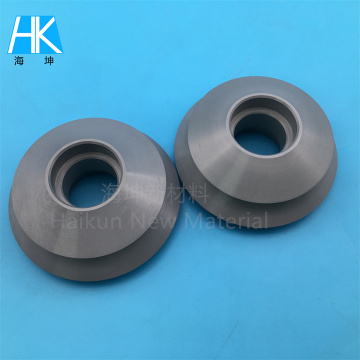

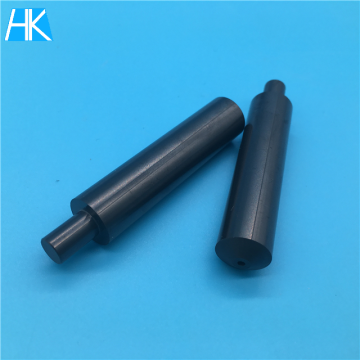

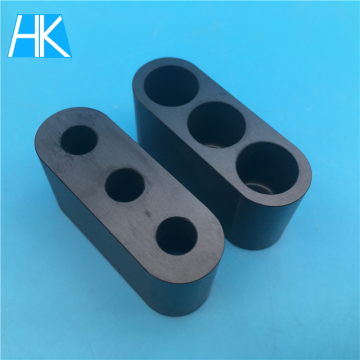

Welding shaft, electronic substrate, plunger, nozzle, slide guide, diesel parts, metal molding, shaft wheels etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords