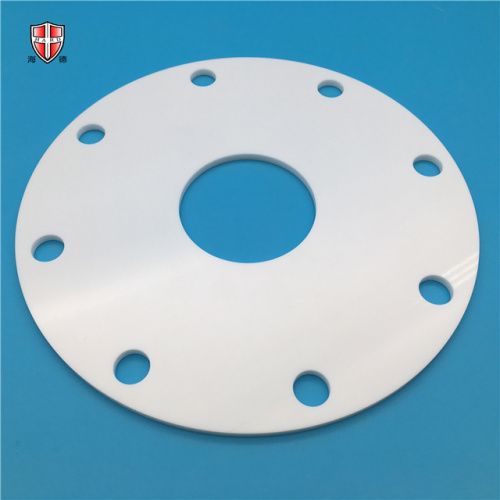

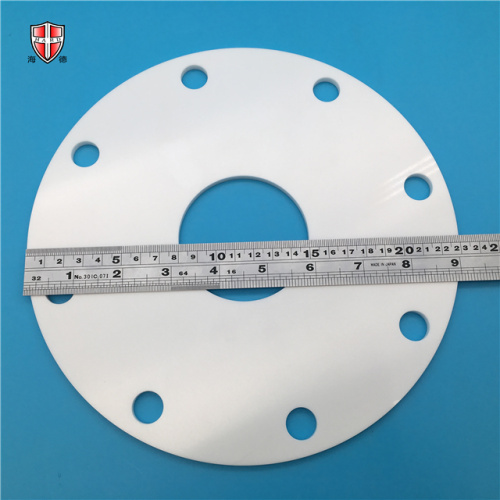

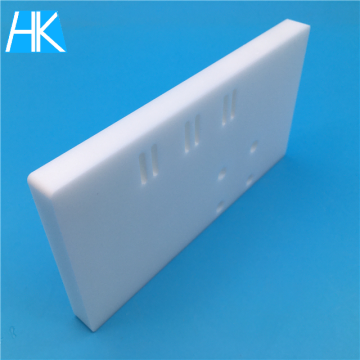

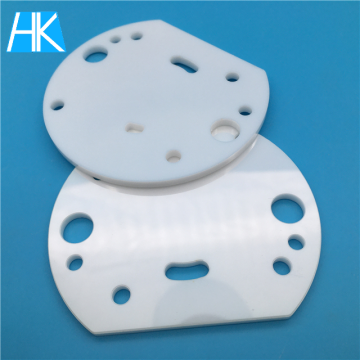

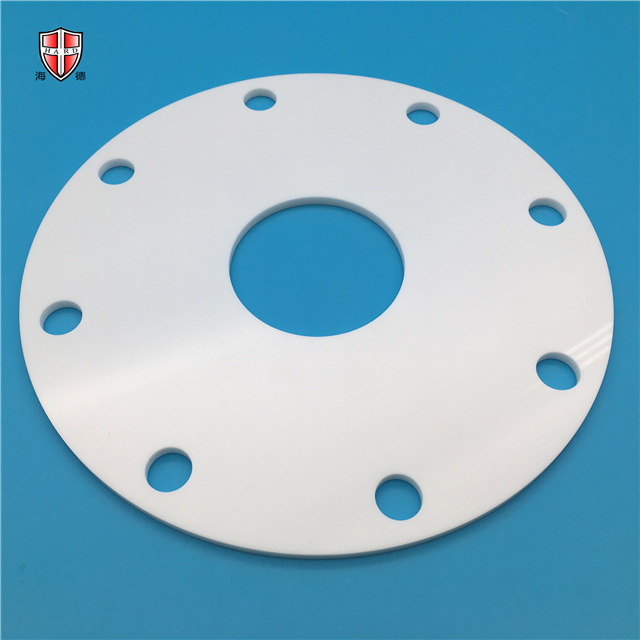

isostatic forming ZrO2 zirconia ceramic disc plate board

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Guangdong,China |

|---|---|

| Supply Ability: | 1,000,000 pcs/Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB |

| Certificate: | SGS |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

isostatic forming ZrO2 zirconia ceramic disc plate board

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Zirconium is a new type of metal. The properties of zirconium are related to the content of impurities such as carbon, nitrogen, hydrogen, and oxygen. The purest titanium iodide has an impurity content of no more than 0.1%, but its strength is low and its plasticity is high. The properties of 99.5% industrial pure titanium are: density ρ=4.5g/cm3, melting point of 1725℃, thermal conductivity λ=15.24W/(mK), tensile strength σb=539MPa, elongation δ=25%, and section shrinkage Rate ψ=25%, elastic modulus E=1.078×105MPa, hardness HB195.

The density of high-strength zirconia ceramics is generally about 6g/cm3, which is only 60% of steel. Some high-strength titanium alloys exceed the strength of many alloy structural steels. Therefore, the specific strength (strength/density) of titanium alloy is much greater than other metal structural materials, and parts with high unit strength, good rigidity and light weight can be produced. The aircraft's engine components, skeletons, skins, fasteners and landing gear all use titanium alloys. High thermal intensity

The service temperature is several hundred degrees higher than that of aluminum alloy. It can still maintain the required strength at medium temperature. It can work for a long time at a temperature of 450~500℃. These two types of titanium alloys are still very high in the range of 150℃~500℃. Specific strength, while the specific strength of aluminum alloy decreases significantly at 150°C. The working temperature of titanium alloy can reach 500℃, while that of aluminum alloy is below 200℃.

Good corrosion resistance

Zirconium oxide works in humid atmosphere and sea water, and its corrosion resistance is far better than stainless steel; it is particularly resistant to pitting, acid corrosion, and stress corrosion; it is resistant to alkali, chloride, chlorine organic substances, nitric acid, and sulfuric acid It has excellent corrosion resistance. However, titanium has poor corrosion resistance to reducing oxygen and chromium salt media.

Good low temperature performance

Zirconia can still maintain its mechanical properties at low and ultra-low temperatures. Titanium alloys with good low temperature performance and extremely low interstitial elements, such as TA7, can maintain a certain degree of plasticity at -253°C. Therefore, titanium alloy is also an important low-temperature structural material.

Data Sheet↓

Color: CustomizedDensity: 6.0g/cm3

Zirconia Content: 94.4%

Gas permeability: 0

Water Absorption: 0

Crystal Size: 0.5um

Rockwell Hardness(45N): 78R45N

Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²)

Flexural Strength(20°C): 800Mpa

Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Thermal Conductivity(20°C-400°C): 2.5W(m.K)

Thermal Expansion Coefficient: 9.6 10-6/°C

Thermal Shock Resistance: 250 △T°C

Application industry:

Machinery, fiber optic, knife, medical, food, petroleum etc.

Specific application:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Related Keywords