Electro-Mechanical pcb Assembly box build service

- Payment Type:

- L/C

- Incoterm:

- FOB

- Transportation:

- Ocean

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | L/C |

|---|---|

| Incoterm: | FOB |

| Transportation: | Ocean |

Product Description

Product Description

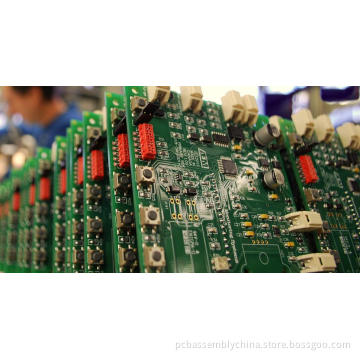

Mechatronics - Electro Mechanical Assembly

Topscoms, CEMS strength in PCB and system assembly, CEMS also offers a comprehensive precision mechatronics assembly service, bringing together electrical, electronic and mechanical assembly skill-sets in the construction of moving mechanical sub-assemblies.

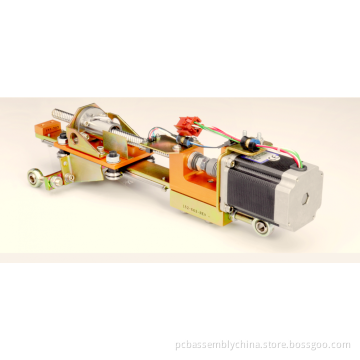

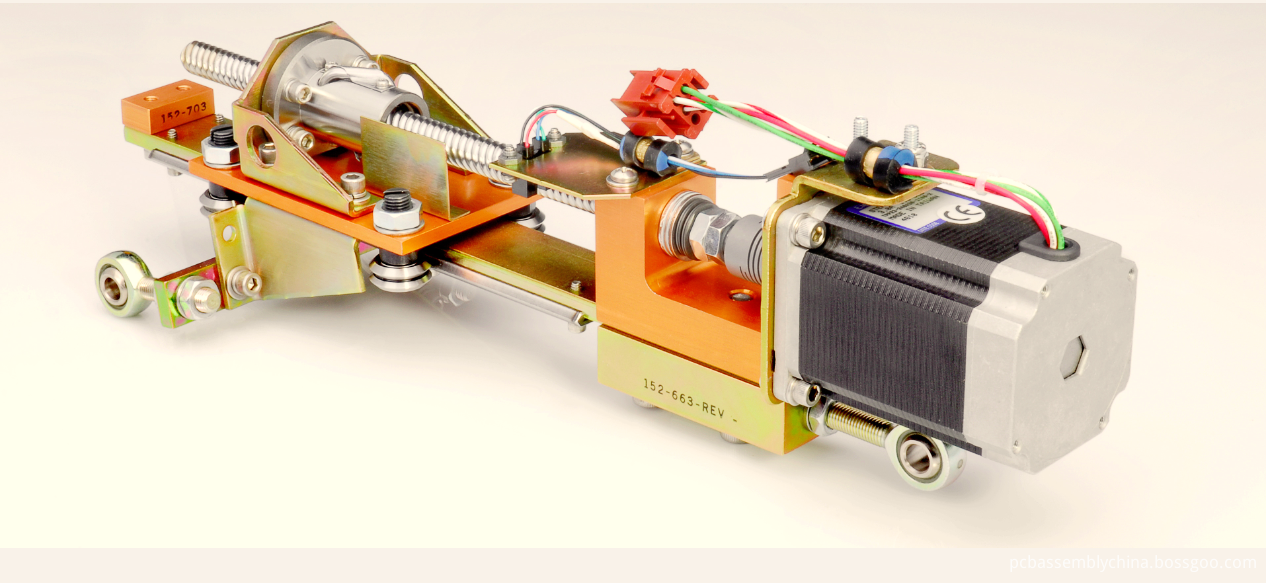

• Precision Mechanical Assembly

• Electrical Assembly

• Structural Plastic Assembly

CEMS operates a rigorous vendor selection process, ensuring that custom made parts, whether metal or plastic, are sourced with the best choice vendor taking account of economics, technical and strategic requirements. CEMS has audited and approved suppliers of custom metal and plastic parts in both Asia and CEE for small to large volumes.

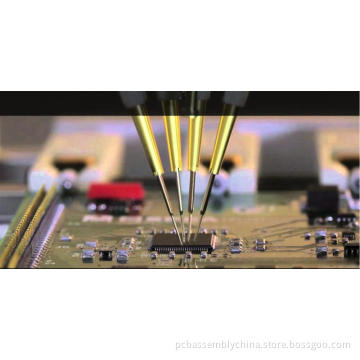

Electrical Assembly

Primarily between electronic devices and sub-assemblies; electrical assembly commonly involves wire and cable interconnection. Achieved by way of bench made cable forms or point to point wiring and often with critical routing to coexist with mechanically moving parts the use of best practice is essential.

The staff at CEMS work to the highest standards and have experience in a range of wire and cable management. Incorporation of stress relief in wiring, often undocumented by the client, can be critical and the experience of years, coupled with comprehensive works instructions ensures that product assembled by CEMS has a long and reliable service life in the field. Solder termination practice at CEMS complies with IPC 622 to further ensure reliability of product.

Structural Plastic Mouldings

As the cost of time rises, designers look to reduce the number of piece parts that combine to form the whole product, thereby reducing assembly time. By way of sophisticated design skills and modern high nylon content precision plastic mouldings the modern mechatronic product can often be significantly cost-reduced by incorporating many of the features and actions of the product within a small number of plastic mouldings.

With the use of mechanically strong precision plastic mouldings comes the requirement for different skill sets and CEMS can demonstrate a wealth of experience in this field.

Test Strategies

CEMS engineering staff are experienced in incorporating elements of electronic, electrical and mechanical engineering to define and produce the optimum test strategy for mechatronics products. Production tests that exercise elements of all aspects of a mechatronic product, to the extent required to provide adequate assurance of product correctness and function whilst remaining within economic limits, are essential. Designers focussed on achieving net functionality of their product are able to enlist the services of a CEMS test engineer to resolve production test issues.

Topscoms, CEMS strength in PCB and system assembly, CEMS also offers a comprehensive precision mechatronics assembly service, bringing together electrical, electronic and mechanical assembly skill-sets in the construction of moving mechanical sub-assemblies.

• Precision Mechanical Assembly

• Electrical Assembly

• Structural Plastic Assembly

• Precision Mechanical Assembly

Precision Mechanical Assembly

CEMS operates a rigorous vendor selection process, ensuring that custom made parts, whether metal or plastic, are sourced with the best choice vendor taking account of economics, technical and strategic requirements. CEMS has audited and approved suppliers of custom metal and plastic parts in both Asia and CEE for small to large volumes.

Electrical Assembly

Primarily between electronic devices and sub-assemblies; electrical assembly commonly involves wire and cable interconnection. Achieved by way of bench made cable forms or point to point wiring and often with critical routing to coexist with mechanically moving parts the use of best practice is essential.

The staff at CEMS work to the highest standards and have experience in a range of wire and cable management. Incorporation of stress relief in wiring, often undocumented by the client, can be critical and the experience of years, coupled with comprehensive works instructions ensures that product assembled by CEMS has a long and reliable service life in the field. Solder termination practice at CEMS complies with IPC 622 to further ensure reliability of product.

Structural Plastic Mouldings

As the cost of time rises, designers look to reduce the number of piece parts that combine to form the whole product, thereby reducing assembly time. By way of sophisticated design skills and modern high nylon content precision plastic mouldings the modern mechatronic product can often be significantly cost-reduced by incorporating many of the features and actions of the product within a small number of plastic mouldings.

With the use of mechanically strong precision plastic mouldings comes the requirement for different skill sets and CEMS can demonstrate a wealth of experience in this field.

Test Strategies

CEMS engineering staff are experienced in incorporating elements of electronic, electrical and mechanical engineering to define and produce the optimum test strategy for mechatronics products. Production tests that exercise elements of all aspects of a mechatronic product, to the extent required to provide adequate assurance of product correctness and function whilst remaining within economic limits, are essential. Designers focussed on achieving net functionality of their product are able to enlist the services of a CEMS test engineer to resolve production test issues.

Related Keywords

Related Keywords