Electronic Pcba box build Manufacturing system integration

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CIF

- Transportation:

- Air

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Transportation: | Air |

Product Description

Product Description

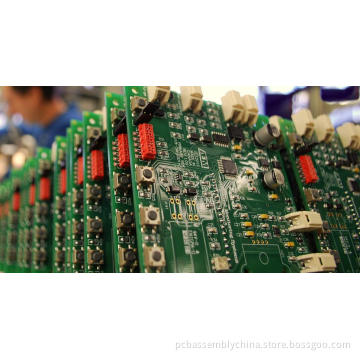

Our Electronics Assembly operations are conducted within an organized and clean manufacturing environment, arranged in line with 5S lean-oriented organized workplace. Our facilities are ESD protected, air conditioned and humidity controlled. We have over 20 years of experience in production of printed circuit board assemblies (PCBA).

General Overview & Capacity:

Production according to international standards

Workmanship standards in line with IPC-A-610 (Class 2 and 3)

Traceability level: based on Customer requirements

High-performance SMT lines: 950,0000 components per hour (cph)

Components placed in 2016: 7000 million (aprox. 3,5 million PCBAs)

Free capacity available and quick ability to increase capacity by 20%-30%

Software Control & Capabilities

Online SMT machine control: Feeder / Machine Slot / Reel validation, PPM level tracking (feeder / component / nozzle tracking), Automatically set Quality Alerts, Consumption level tracking

Traceability

Online Material Consumption reporting by component/reel

Production Management Systems

Quality Data (reporting, reflow profiles, AOI, SPI, Xray, test ) record system & historical data

Valor Vplan – defect-free NPI production

SMT production (technology)

Stencil Printing (3D inspection, Hawkeye)

Dispense technology (glue, paste)

Placement of 01005, BGA/CSP, QFP, uBGA

Pin-in-Paste technology

Reflow soldering in nitrogen atmoshpere

Inline AOI in each SMT line

THT production:

Radial/VCD automatic insertion and manual placement

Wave soldering in nitrogen atmosphere

Manual soldering

Depaneling (router, punch)

AOI inspection

PCB protection:

Advanced conformal coating (partial, angle)

Potting

Inspection:

SPI (Solder Paste Inspection)

X-Ray

Inline AOI for SMT

Offline AOI for THT

Test:

In-house test development (functional test, in-process verification tests)

In-circuit test (ICT)

Functional test

Safety tests (high voltage)

RoHS tests (X-ray fluorescence)

Burn-in (aging) test

Environmental tests

pcb assembly, electronics contract manufacturing services,china pcb smt assembly,pcba and printed circuit boards assembly services, oem manufacturing,electronic pcb assembly,china supplier manufacturer companies factory, Topscom Technology.

General Overview & Capacity:

Production according to international standards

Workmanship standards in line with IPC-A-610 (Class 2 and 3)

Traceability level: based on Customer requirements

High-performance SMT lines: 950,0000 components per hour (cph)

Components placed in 2016: 7000 million (aprox. 3,5 million PCBAs)

Free capacity available and quick ability to increase capacity by 20%-30%

Software Control & Capabilities

Online SMT machine control: Feeder / Machine Slot / Reel validation, PPM level tracking (feeder / component / nozzle tracking), Automatically set Quality Alerts, Consumption level tracking

Traceability

Online Material Consumption reporting by component/reel

Production Management Systems

Quality Data (reporting, reflow profiles, AOI, SPI, Xray, test ) record system & historical data

Valor Vplan – defect-free NPI production

SMT production (technology)

Stencil Printing (3D inspection, Hawkeye)

Dispense technology (glue, paste)

Placement of 01005, BGA/CSP, QFP, uBGA

Pin-in-Paste technology

Reflow soldering in nitrogen atmoshpere

Inline AOI in each SMT line

THT production:

Radial/VCD automatic insertion and manual placement

Wave soldering in nitrogen atmosphere

Manual soldering

Depaneling (router, punch)

AOI inspection

PCB protection:

Advanced conformal coating (partial, angle)

Potting

Inspection:

SPI (Solder Paste Inspection)

X-Ray

Inline AOI for SMT

Offline AOI for THT

Test:

In-house test development (functional test, in-process verification tests)

In-circuit test (ICT)

Functional test

Safety tests (high voltage)

RoHS tests (X-ray fluorescence)

Burn-in (aging) test

Environmental tests

Related Keywords

Related Keywords