Contract Oem Cem Ems Manufacturing Service

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

Electronic OEM EMS CEM Contract Manufacturing

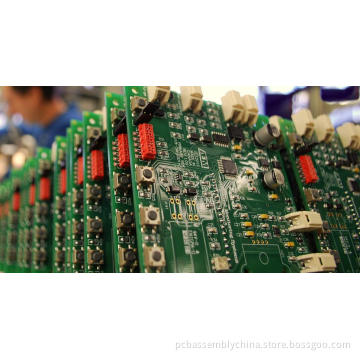

PCB Assembly

PCB assembly forms a core part of our electronics manufacturing services (EMS). This capability can be utilized at all levels from the initial production of very low volume (NPI, EVT, PVT), rapid prototype products, through to the ongoing manufacture of complex, multi-technology PCB assembly. With our automated SMT Assembly lines Ever Sparkle achieves more than 2.5 million SMT placement per day from 0201 sized chip components to micro BGAs.

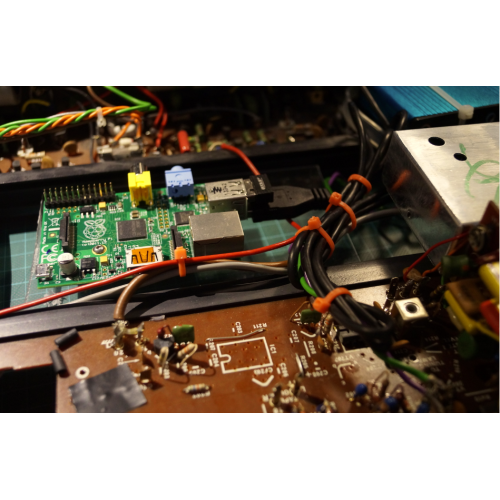

Picture

PCB Assembly Line

We have full capability for assembling both Through-Hole and mixed technology PCB assembly and also offer a number of peripheral services such as conformal coating and potting etc. In addition, we also undertake device programming and the configuration of PCB assemblies prior to system integration before dispatch.

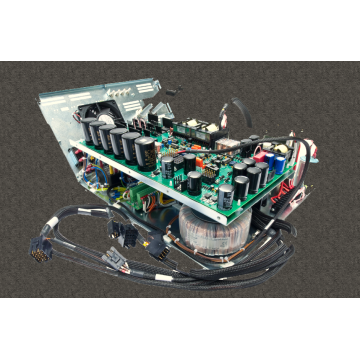

Box Build Assembly Line

Our Box Build Assembly solutions typically focus on complex electronics which require high degrees of configuration and system integration prior to dispatch. With our strong available box build assembly labor force of over 1000 production operators, we trained to handle complex assembly electronic products in the most effective and efficient process in order to provide our clients shortest delivery lead time with competitive costs.

pcb assembly, electronics contract manufacturing services,china pcb smt assembly,pcba and printed circuit boards assembly services, oem manufacturing,electronic pcb assembly,china supplier manufacturer companies factory assembler,chinese turnkey box build systems integration outsource assembler outsourcing, Topscom Technology.

pcb assembly, electronics contract manufacturing services,china pcb smt assembly,pcba and printed circuit boards assembly services, oem manufacturing,electronic pcb assembly,china supplier manufacturer companies factory assembler,chinese turnkey box build systems integration outsource assembler outsourcing, Topscom Technology.

PCB Assembly

PCB assembly forms a core part of our electronics manufacturing services (EMS). This capability can be utilized at all levels from the initial production of very low volume (NPI, EVT, PVT), rapid prototype products, through to the ongoing manufacture of complex, multi-technology PCB assembly. With our automated SMT Assembly lines Ever Sparkle achieves more than 2.5 million SMT placement per day from 0201 sized chip components to micro BGAs.

Picture

PCB Assembly Line

We have full capability for assembling both Through-Hole and mixed technology PCB assembly and also offer a number of peripheral services such as conformal coating and potting etc. In addition, we also undertake device programming and the configuration of PCB assemblies prior to system integration before dispatch.

Box Build Assembly Line

Our Box Build Assembly solutions typically focus on complex electronics which require high degrees of configuration and system integration prior to dispatch. With our strong available box build assembly labor force of over 1000 production operators, we trained to handle complex assembly electronic products in the most effective and efficient process in order to provide our clients shortest delivery lead time with competitive costs.

pcb assembly, electronics contract manufacturing services,china pcb smt assembly,pcba and printed circuit boards assembly services, oem manufacturing,electronic pcb assembly,china supplier manufacturer companies factory assembler,chinese turnkey box build systems integration outsource assembler outsourcing, Topscom Technology.

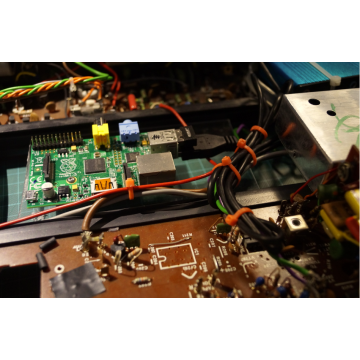

otal turn-key capabilities - We will take your project from idea to finished product efficiently and cost-effectively. Our commitment to quality is unrivalled in the industry

Dedicated problem solvers - We have a long history of successfully executing on complex projects. Our expert engineers and technicians rarely meet a project they can`t handle. Often we are able to re-engineer or reverse engineer legacy projects and save our clients money. In other cases, we will suggest options that will reduce your costs and improve quality. The goal at OEM is always on meeting our customers` needs and assuring your highest satisfaction.

Related Keywords

Related Keywords