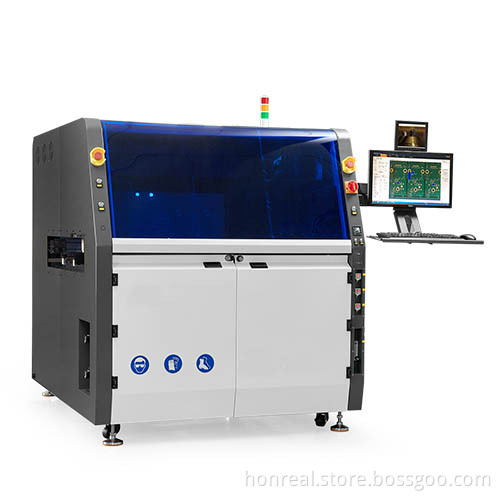

Online small selective wave soldering machine

-

$10000.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

Your message must be between 20 to 2000 characters

Contact Now

HR-400C Features:

1.On-line transportation,and it can realize on-line production with the previous section of machine.

2.The machine integrates flux spraying,preheating and soldering into whole.

3.By progam switching ,it can only select spraying,only select soldering,or firstly select spraying and then soldering.

4.The maximum PCB dimensions:400 x 400mm.

5.Small in occupation space and low in energy consumption.

6.It is suitable for high quality,small batch and multiple variety.

7.The optimum flexibility.

Technical parameter:

|

Machine name |

HR-400C |

|

|

General |

||

|

dimension |

L1400mm x W1450mm x H1700mm |

|

|

general power |

7kw |

|

|

consumption power |

2--4kw |

|

|

power supply |

Single-phase 220V 50HZ |

|

|

net weight |

700KG |

|

|

reuiqred air source |

3-5 Bars |

|

|

required air flow |

8-12L/min |

|

|

required N2 pressure |

3-4 Bars |

|

|

required N2 flow |

more than 2cubic meter per hour |

|

|

required N2 purity |

>99.998% |

|

|

required exhausting |

500--800CMB/H |

|

|

carrier or PCB |

||

|

carrier |

according product |

|

|

max carrier size |

L400 x W400 mm |

|

|

max solder area |

L400 x W400 mm |

|

|

PCB thickness |

0.2mm-----6mm |

|

|

pcb edge |

3mm or more |

|

|

controlling & conveyor |

||

|

controlling |

Industrial PC |

|

|

conveyor width |

50-400MM |

|

|

conveyor type |

SUS roller |

|

|

conveyor thick |

1.5---4mm(edge thickness or carrier thickness) |

|

|

PCB conveyor direction |

Left to right |

|

|

PCB conveyor up clearance |

50MM |

|

|

PCB conveyor bottom clearance |

30MM |

|

|

conveyor load |

<5kg |

|

|

conveyor rail |

Aluminum rail |

|

|

conveyor height |

900+/-30mm |

|

|

Motion table |

||

|

motion axis |

X, Y, Z |

|

|

motion control |

Closed-loop servo control |

|

|

motion motor |

Panasonic servo motor |

|

|

ball screw |

Hiwin |

|

|

position accuracy |

+ / - 0.05 mm |

|

|

chassis |

metal welding |

|

|

Flux management |

||

|

flux nozzle |

Japan Lumina |

|

|

nozzle durability |

stainless steel |

|

|

flux tank capacity |

1L |

|

|

flux tank |

pressure tank |

|

|

alcohol tank capacity |

1L |

|

|

alcohol tank |

pressure tank |

|

|

Preheat |

||

|

preheat method |

upper IR heating |

|

|

heater’s power |

3kw |

|

|

temperature range |

25--240c degree |

|

|

solder pot |

||

|

standard pot number |

1pcs |

|

|

solder pot capacity |

15 kgs / solder pot |

|

|

solder temperature Control |

PID |

|

|

melting time |

20--30 Minutes |

|

|

max solder temperature |

350 C |

|

|

solder heater |

1.2kw |

|

|

solder nozzle |

||

|

nozzle dim |

customized |

|

|

material |

high carbon alloy |

|

|

standard equipped nozzle |

standard equipped 5pcs/ solder pot(the inside diameter of nozzle 2.5mm, 3mm, 4mm, 5mm,6mm ) |

|

|

N2 management |

||

|

N2 heater |

standard equipped |

|

|

PID N2 temp range |

0 - 350 C |

|

|

N2 consumption |

1-2 m³ /h / nozzle |

|

Related Keywords