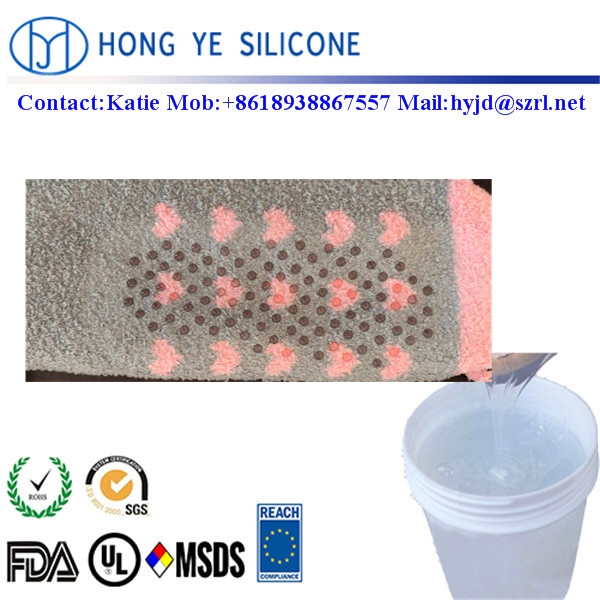

Liquid screen printing silicone rubber ink for antiskid socks

- Payment Type:

- L/C, T/T, Paypal

- Incoterm:

- FOB, CIF

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Delivery Time:

- 4 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 8 tons per day |

| Supply Ability: | 8 tons per day |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CIF |

| Certificate: | ul,fda |

| HS Code: | 31900000 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

Liquid screen printing silicone rubber ink for antiskid socks

Technical Parameters

|

Model |

Viscosity (cps) |

Hardness (A°) |

Tensile Strength (Mpa) |

Tear Strength (kN/m) |

Elongation (≥%) |

Mixing ratio |

Curing Time(Min) |

|

TB3220 |

65000-100000 |

20 |

3.5 |

17 |

350 |

1:1/10:1 |

3 |

NOTE: the viscosity can meet the requirement of customers.

Characteristics

-Low shrinkage(<0.1%)

-Good skid-proof effect and high adhesive strength

-Wearproof, wash-resistant, high temperature resistant

-Non-toxic and odorless, food grade silicone

-High transparency and good tear-strength.

Operation instructions

1. Add the pigment to the curing agent ( Part B ) with the ratio of 10:1 and stir them evenly.

2. Mix Part A and Part B as ratio 1:1 and stir them evenly.

3. Printing the mixture on the print demo

4. Curing it by heating

NOTE:

1. If no need to add the pigment, you can mix part A and part B directly

2. It can be cured by heating with 100~150 degree, the curing time will be 30~60 seconds.

3. Pot life: It`s easier to be operated with longer curing time.

FAQ of screen printing silicoen rubber

1. Don`t cure enough.

Reason: First, related to customers operation temperature. Second, re;ated to the thickness of the silicoen they brushed

2. Sticky.

Reason: First, related to the product material, may be semi-cureed when it`s be oisoned( a chemical reaction ). second, temperature is not heated highly enough.

3. There`s bubbles existing.

Reason: it is brushed too thick, and the temperature is too high so that it cures immediataly before the bubble comes out.

4. Surface is not smooth.

Reason: it is not brushed evenly.

Shelf life

Twelve(12) months when stored under dry and cool place by original package under 25℃

This kind of product is non-dangerous product, which could be transported as general chemicals.

1. We accept T/T,L/C for big amount.

2. For small amount, you can pay us by Paypal, Western Union.

For more information , please feel free to contact Katie

Office No. : 0086-755-89948294

Mob(Whats app) : +8618938867557

Email : hyjd(at)szrl(dot)net

Related Keywords