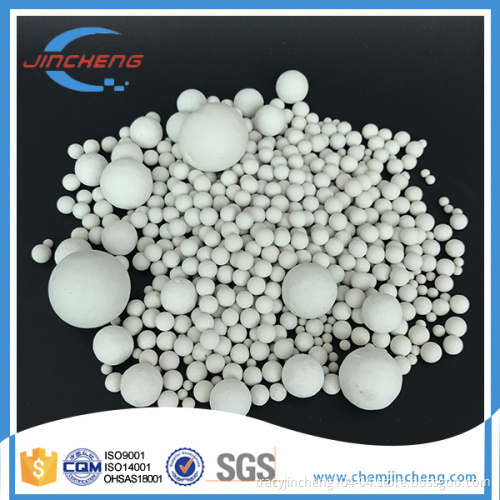

3-50mm Inert Alumina Ceramic Ball as Catalyst Support Media

- Payment Type:

- L/C, T/T, D/P, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 5000 Metric Tons / Year. |

| Supply Ability: | 5000 Metric Tons / Year. |

| Payment Type: | L/C, T/T, D/P, Western Union |

Product Description

Product Description

Model NO.: 3mm, 6mm, 10mm, 13mm, 19mm, 25mm

Size: 6mm, 10mm, 13mm, 19mm, 25mm, 38mm, 50mm

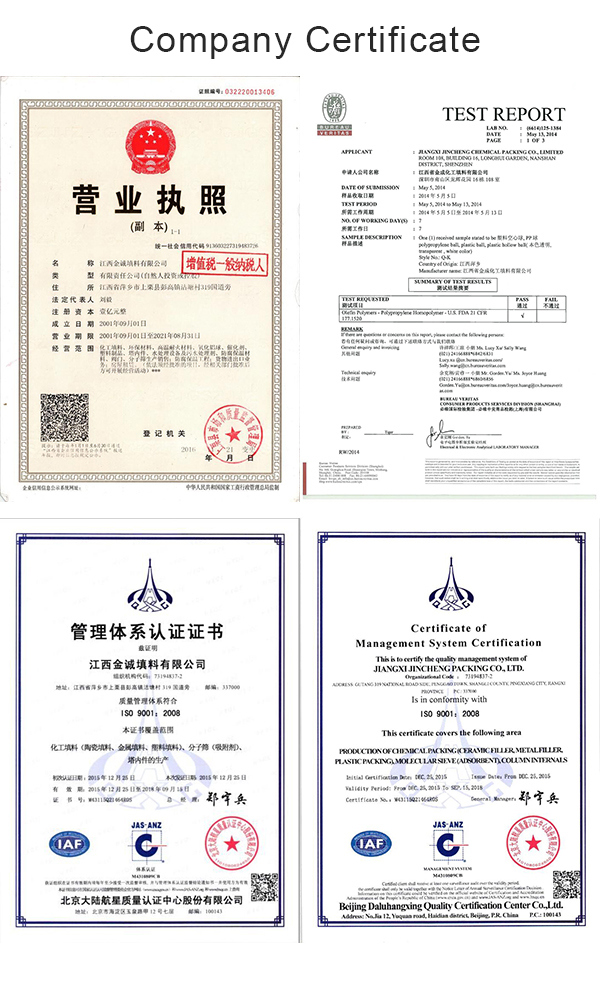

Certificate: ISO9001: 2000

Trademark: JINCHENG

Transport Package: by Double Layer Plastic Bag, Each Box 25kgs Net.

Specification: 3mm, 6mm, 9mm, 13mm, 19mm, 25mm, 50mm

Origin: China

HS Code: 6909110000

Inert Ceramic balls are the most widely used support media in the world because of their excellent consistence and reliability. Products to these specifications are manufactured from very high quality chemical-porcelain clay materials, which has quite excellent stability, high mechanical strengthand resistance to thermal shock, This makes them all ideal choice for support of all types of catalyst.|

Chemical composition |

||||

| Typical Technical Composition | Min.% | Max.% | Usual% | |

| SiO2 | 64.00 | 75.00 | 68.40 | |

| Al2O3 | 19.00 | 26.00 | 24.50 | |

| Fe2O3 | ****** | 1.60 | 0.94 | |

| TiO2 | ****** | 1.40 | 0.96 | |

| CaO | ****** | 0.65 | 0.42 | |

| MgO | ****** | 0.60 | 0.38 | |

| Na2O | ****** | 2.00 | 1.12 | |

| K2O | ****** | 3.50 | 3.28 | |

| Al2O3+ SiO2 | 90.00 | 96.00 | 92.90 | |

| Physical properties | ||||

| Index | Value | Value | ||

| Leachable Iron | ≤0.1% | ****** | ||

| Apparent Porosity by Weight, dia≥10mm | ≤0.4% | ****** | ||

| Apparent Porosity by Weight, dia= 6mm | ≤1.0% | ****** | ||

| Apparent Porosity by Weight, dia= 3mm | ≤3.0% | ****** | ||

| Moh's Hardness Scale | >6.5 | ****** | ||

| Water Absorption | <1.0wt.% | ****** | ||

| Acid Resistance | >99.8% | ****** | ||

| Thermal Conductivity | 0.9-1.0w/m 2 .k | ****** | ||

| Thermal Expansion @500 degree C | 0.20% | ****** | ||

| Specific Heat | 628-837j/kgq | ****** | ||

| Thermal Shock Stability, 500 degree Cthen water cooling | 10 times | ****** | ||

| Max. Operating Temperature | 1050 degree C | 1922 degree F | ||

| Specific Density | 2,300 kg/m 3 | 144 lb /ft 3 | ||

| Bulk Density (Packing Density) | 1,350 kg/m 3 | 84 lb /ft 3 | ||

| Crush Strength | ||||

| Size | Crush Strength | |||

| Normal Size | (lbs) | (kg) | (N/pc) | |

| mm | inch | min. | min. | min. |

| 3 | 1/8 | 50 | 23 | 225 |

| 6 | 1/4 | 123 | 56 | 550 |

| 10 | 3/8 | 202 | 92 | 902 |

| 13 | 1/2 | 385 | 175 | 1716 |

| 16 | 5/8 | 520 | 236 | 2315 |

| 19 | 3/4 | 978 | 444 | 4355 |

| 25 | 1 | 1428 | 648 | 6355 |

| 38 | 1-1/2 | 2020 | 916 | 8983 |

| 50 | 2 | 2987 | 1355 | 13288 |

Related Keywords

Related Keywords

You May Also Like

You May Also Like