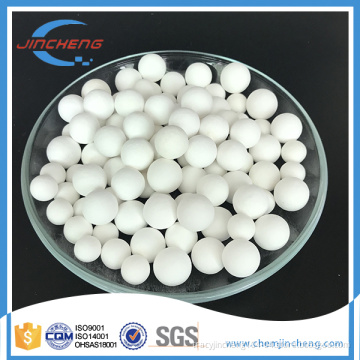

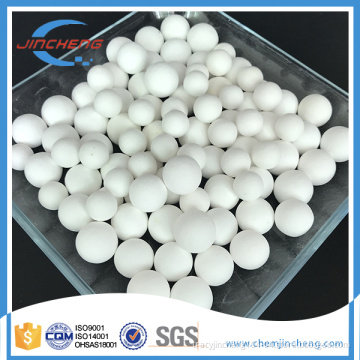

99% Pure Alumina Ball for Catalyst Support Media for Petrochemical Industry

- Payment Type:

- L/C, T/T, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 5000 Metric Tons/Year |

| Supply Ability: | 5000 Metric Tons/Year |

| Payment Type: | L/C, T/T, Western Union |

Product Description

Product Description

Model NO.: 3mm, 6mm, 10mm, 13mm, 19mm, 25mm

Size: 6mm, 10mm, 13mm, 19mm, 25mm, 38mm, 50mm

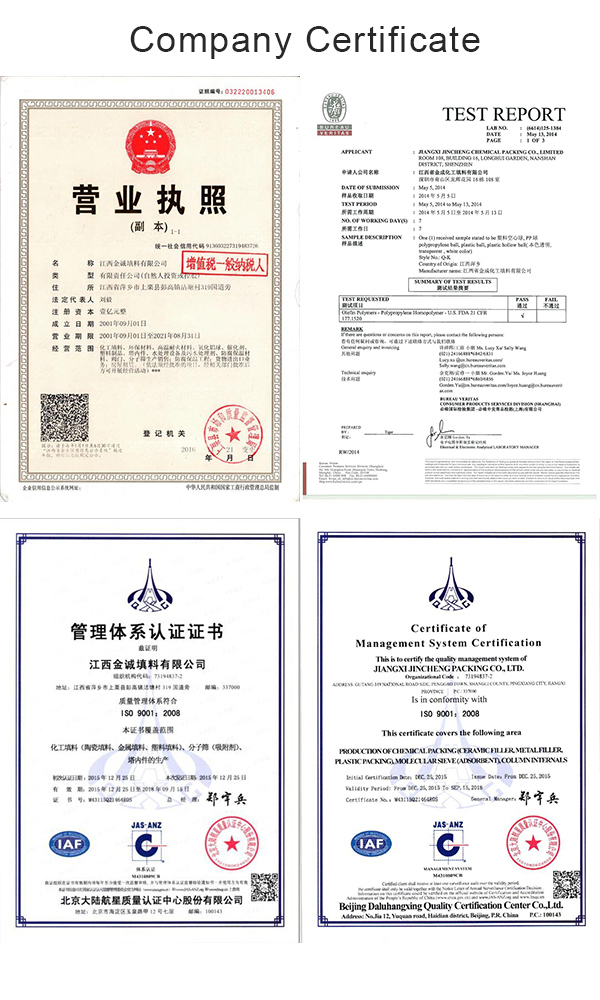

Certificate: ISO9001: 2000

Trademark: JINCHENG

Transport Package: 25kgs/Plastic Bag, or 250kgs Per Steel Drum,Pallet

Specification: 3mm, 6mm, 13mm, 19mm, 25mm, 50mm etc.

Origin: China

HS Code: 6909110000

99% High Alumina BallsJincheng Catalyst Bed Support Media 99% is equal Denstone 99 Support Media. It is in chemical composition99+% alpha alumina and a maximum 0.2wt% SiO2. Because of its high alumina content and low silica (SiO2 ), it's a very excellent and ideal product for high temperature and steam applications, such as secondary reformers in ammonia processing, where leached silica will coat downstream equipment or foul the catalyst bed.

The Jincheng 99% High Alumina Support Media has very excellent thermal properties, with its high density high-temperature resistance 1550Centigrade, also it's a good choice for heat retention or equilibration media.

For its superior chemical resistance, it's suitable for applications in olefin processes, such as ethylene dryers, where there's the polymerization problem.

| Chemical composition | ||||

| Typical Technical Composition | Min.% | Max.% | Usual% | |

| SiO2 | ******* | 0.20 | 0.18 | |

| Al2O3 | 99.00 | 99.60 | 99.30 | |

| Fe2O3 | ****** | 0.10 | 0.02 | |

| TiO2 | ****** | 0.55 | 0.02 | |

| CaO | ****** | 0.10 | 0.05 | |

| MgO | ****** | 0.10 | 0.05 | |

| Na2O | ****** | 0.10 | 0.08 | |

| K2O | ****** | 0.10 | 0.08 | |

| Physical properties | ||||

| Index | Value | Value | ||

| Leachable Iron | ≤0.01% | |||

| Apparent Porosity by Weight | ≤7.0% | |||

| Moh's Hardness Scale | >8.0 | |||

| Water Absorption | <4.0wt.% | |||

| Acid Resistance | >99.8% | |||

| Thermal Conductivity | 0.7-0.8w/m 2.k | |||

| Thermal Expansion @500 Centigrade | 0.10% | |||

| Thermal Shock Stability, 1000 Centigrade then water cooling | 10 times | |||

| Max. Operating Temperature | 1550 Centigrade | 2822 Centigrade | ||

| Specific Density | 3,700 kg/m3 | 231 lb /ft 3 | ||

| Bulk Density (Packing Density) | 2,100 kg/m3 | 131 lb /ft 3 | ||

| Crush Strength | ||||

| Size | Crush Strength | |||

| Normal Size | (lbs) | (kg) | (N/pc) | |

| mm | inch | min. | min. | min. |

| 3 | 1/8 | 115 | 52 | 510 |

| 6 | 1/4 | 230 | 105 | 1030 |

| 10 | 3/8 | 440 | 200 | 1961 |

| 13 | 1/2 | 1355 | 615 | 6031 |

| 16 | 5/8 | 1720 | 780 | 7650 |

| 19 | 3/4 | 2315 | 1050 | 10297 |

| 25 | 1 | 3130 | 1420 | 13925 |

| 38 | 1-1/2 | 4034 | 1830 | 17946 |

| 50 | 2 | 4960 | 2250 | 22065 |

Related Keywords

Related Keywords

You May Also Like

You May Also Like