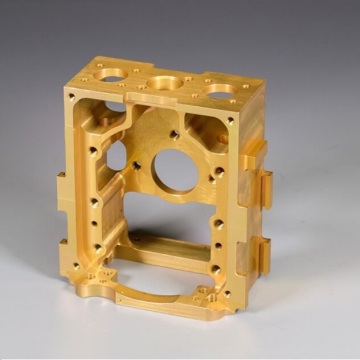

High Demand Products OEM Cnc Machined Brass Parts

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 10 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 20000 Piece/Pieces |

| Supply Ability: | 100000 pieces per Month |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| Certificate: | ISO 9001,ISO 14001 |

| HS Code: | 518100 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

High Demand Products OEM Cnc Machined Brass Parts

The structure of complex brass can be calculated based on the "zinc equivalent coefficient" of elements added to brass. Because a small amount of other alloying elements are added to the copper-zinc alloy, the α / (α + β) phase zone in the Cu-Zn state diagram is usually moved to the left or right. Therefore, the structure of special brass is usually equivalent to the structure of ordinary brass that has increased or decreased zinc content. For example, the structure after adding 1% silicon to the Cu-Zn alloy is equivalent to the alloy structure adding 10% zinc to the Cu-Zn alloy. So the "zinc equivalent" of silicon is 10. The "zinc equivalent coefficient" of silicon is the largest, which makes the α / (α + β) phase boundary in the Cu-Zn system move significantly to the copper side, that is, the α phase region is strongly reduced. Nickel's "zinc equivalent coefficient" is a negative value, which expands the alpha phase region.

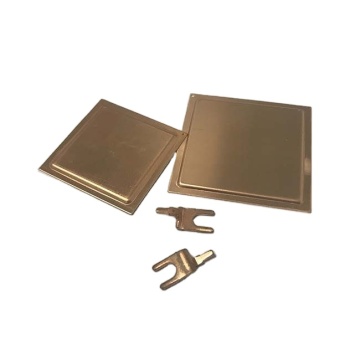

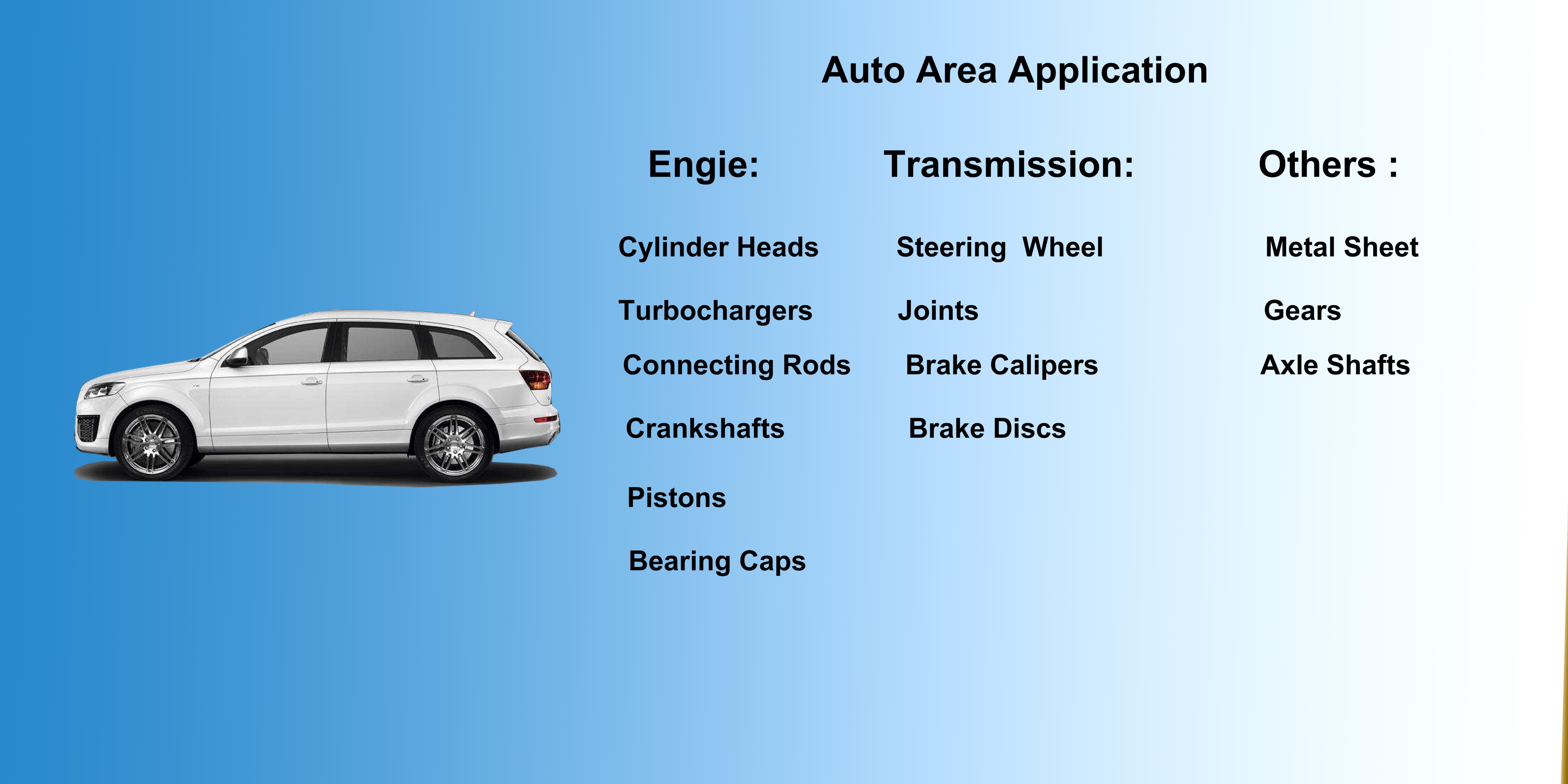

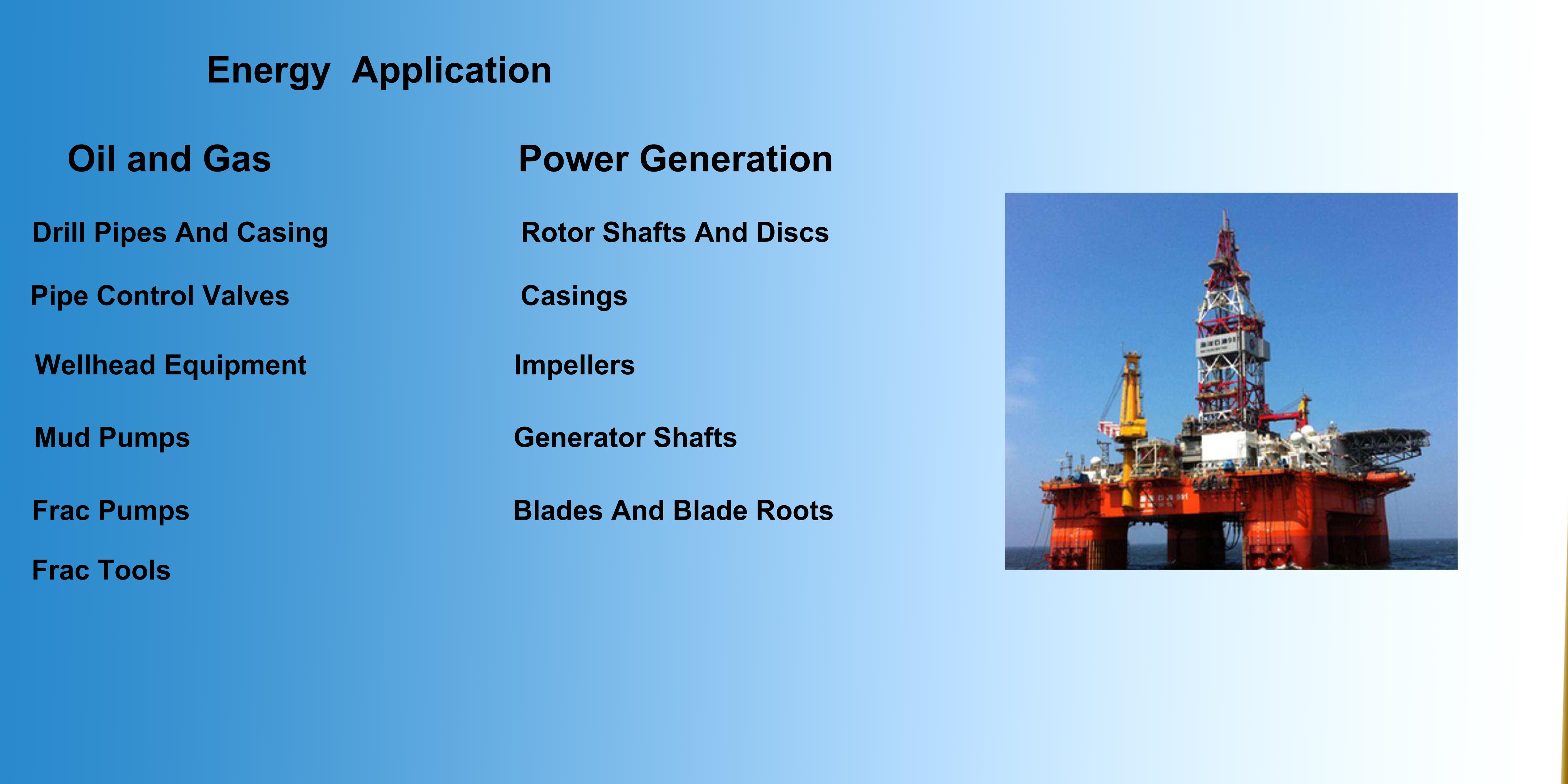

We are OEM. Main producetion metal &plastic parts and main business scope is CNC Turning Machining ,CNC Milling Machining,CNC Machining Parts,Plastic Parts,Sheet Metal,Die Casting and so on.

|

Material Range |

Aluminum,Stainless Steel, Brass,Copper, Brozone, Titanium, Carbon Steel ,Alloy,Plastic etc. |

|

Production Technology |

CNC Turning,CNC Milling,Metal Sheet,Stampling,Die Casting,Forging etc. |

|

Surface Finish |

Based on customer requirements, we can do Plating(Zinc plated, Nickel plated, Chrome plated,etc), polishing(precision can reach +/-0.005mm), knurling, anodizing, Black Oxide, heat treatment, sandblasting, powder coating, etc. |

|

Precision Processing |

turning, milling, drilling, grinding, wire-EDM cutting etc |

|

Tolerance |

0.003mm-0.01mm |

Related Keywords