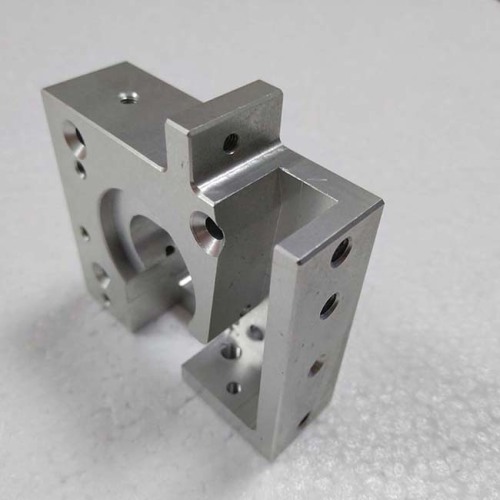

Customized Factory CNC Machine Parts Stainless Steel Block

- Payment Type:

- T/T, Paypal, Western Union

- Incoterm:

- FOB, CIF

- Min. Order:

- 5 Piece/Pieces

- Min. Order:

- 5 Piece/Pieces

- Delivery Time:

- 8 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen,China |

|---|---|

| Productivity: | 20000 Piece/Pieces |

| Supply Ability: | 100000 pieces per Month |

| Payment Type: | T/T,Paypal,Western Union |

| Incoterm: | FOB,CIF |

| Certificate: | ISO 9001,ISO 14001 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

Customized Factory CNC Machine Parts Stainless Steel Block

When milling a plane, you must use a cutter head with more than four cutter heads, select the appropriate cutting amount, and prevent the machine tool from generating vibration during milling. When the worktable is commutated, the commutation handle must be stopped in the middle position first, and then commutated. Direct commutation is not allowed. When milling keyway shafts or cutting thin workpieces, prevent the indexing head or worktable from being damaged.

We are OEM. Main producetion metal &plastic parts and main business scope is CNC Turning Machining ,CNC Milling Machining,CNC Machining Parts,Plastic Parts,Sheet Metal,Die Casting and so on.

Material Range

Aluminum,Stainless Steel, Brass,Copper, Brozone, Titanium, Carbon Steel ,Alloy,Plastic etc.

Production Technology

CNC Turning,CNC Milling,Metal Sheet,Stampling,Die Casting,Forging etc.

Surface Finish

Based on customer requirements, we can do Plating(Zinc plated, Nickel plated, Chrome plated,etc), polishing(precision can reach

+/-0.005mm), knurling, anodizing, Black Oxide, heat treatment, sandblasting, powder coating, etc.

Precision Processing

turning, milling, drilling, grinding, wire-EDM cutting etc

Tolerance

0.003mm-0.01mm

+/-0.005mm), knurling, anodizing, Black Oxide, heat treatment, sandblasting, powder coating, etc.

Wholesales Customized 7075 Aluminum Machining Parts

Metal surface painting is a method to protect metals from oxidation and corrosion. The corrosion phenomenon that occurs around us refers to the damage, degradation of performance or compression of various materials under the action of the environment (the combined effect of chemical, electrochemical and certain physical factors). Paint spraying on metal surfaces is a very important means of maintaining metal corrosion protection. A good spray paint coating protection layer is kept continuous and intact, and the combination is good, which can become a barrier to inhibit the invasion of corrosive media.

We are OEM. Main producetion metal &plastic parts and main business scope is CNC Turning Machining ,CNC Milling Machining,CNC Machining Parts,Plastic Parts,Sheet Metal,Die Casting and so on.

Material Range

Aluminum,Stainless Steel, Brass,Copper, Brozone, Titanium, Carbon Steel ,Alloy,Plastic etc.

Production Technology

CNC Turning,CNC Milling,Metal Sheet,Stampling,Die Casting,Forging etc.

Surface Finish

Based on customer requirements, we can do Plating(Zinc plated, Nickel plated, Chrome plated,etc), polishing(precision can reach

+/-0.005mm), knurling, anodizing, Black Oxide, heat treatment, sandblasting, powder coating, etc.

Precision Processing

turning, milling, drilling, grinding, wire-EDM cutting etc

Tolerance

0.003mm-0.01mm

+/-0.005mm), knurling, anodizing, Black Oxide, heat treatment, sandblasting, powder coating, etc.

Related Keywords