High Power LED PCB Star PCB Fabrication and assembly

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Ocean, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 40000 Square Meters / Month |

| Supply Ability: | 40000 Square Meters / Month |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO9001 |

| Transportation: | Ocean,Air |

| Port: | Shenzhen |

High Power LED Chip light PCB Star PCB Fabrication and assembly

LED PCB, one typeof MCPCB – MCPCB (Metal Core PCB) are those boards which incorporate a base metal material as heat spreader as an integral part of the circuit board. The metal core usually consists of aluminum alloy. Furthermore MCPCB can take advantage of incorporating a dielectric polymer layer with high thermal conductivity for lower thermal resistance.

High power light-emitting diodes (LEDs) can use 350 milliwatts or more in a single LED. Most of the electricity in an LED becomes heat rather than light (about 70% heat and 30% light).[1] If this heat is not removed, the LEDs run at high temperatures, which not only lowers their efficiency, but also makes the LED less reliable. Thus, thermal management of high power LEDs is a crucial area of research and development. It is necessary to limit both the junction and the phosphor particles temperatures to a value that will guarantee the desired LED lifetime.

Heat transfer procedure

One of the problems that high power LED PCB must solve is heat conduction and heat dissipation.

In order to maintain a low junction temperature to keep good performance of an LED, every method of removing heat from LEDs should be considered. Conduction, convection, and radiation are the three means of heat transfer. Typically, LEDs are encapsulated in a transparent polyurethane-based resin, which is a poor thermal conductor. Nearly all heat produced is conducted through the back side of the chip.[4] Heat is generated from the p–n junction by electrical energy that was not converted to useful light, and conducted to outside ambience through a long path, from junction to solder point, solder point to board, and board to the heat sink and then to the atmosphere. A typical LED side view and its thermal model are shown in the figures.

The junction temperature will be lower if the thermal impedance is smaller and likewise, with a lower ambient temperature. To maximize the useful ambient temperature range for a given power dissipation, the total thermal resistance from junction to ambient must be minimized.

The values for the thermal resistance vary widely depending on the material or component supplier. For example, RJC will range from 2.6 °C/W to 18 °C/W, depending on the LED manufacturer. The thermal interface material’s (TIM) thermal resistance will also vary depending on the type of material selected. Common TIMs are epoxy, thermal grease, pressure-sensitive adhesive and solder. Power LEDs are often mounted on metal-core printed circuit boards (MCPCB), which will be attached to a heat sink. Heat conducted through the MCPCB and heat sink is dissipated by convection and radiation. In the package design, the surface flatness and quality of each component, applied mounting pressure, contact area, the type of interface material and its thickness are all important parameters to thermal resistance design.

Order Notes,

As is known, PCB and PCBA is a customized product, so the details, please contact us and a quotation will be offered.

Please send us PCB files in gerber files, ".pcbdoc", ".lay", ".lay6" or ".brd", "CAM350 RS274X", "Protel 99SE", "P-CAD 2001 PCB", etc.

For the PCBA quotation, the BOM list in the format of "xls" is also needed.

Jinghongyi PCB (HK) Co., Limited

Jinghongyi PCB (HK) Co., Limited is a professional manufacturer of high-quality PCB. JHY PCB specializes in Quick Turn PCB prototypes, small-medium volume PCB. Established in 2011, located in Baoan District, Shenzhen, China, with more than 500 experienced employees, we're able to achieve a monthly output of 40000 square meters.

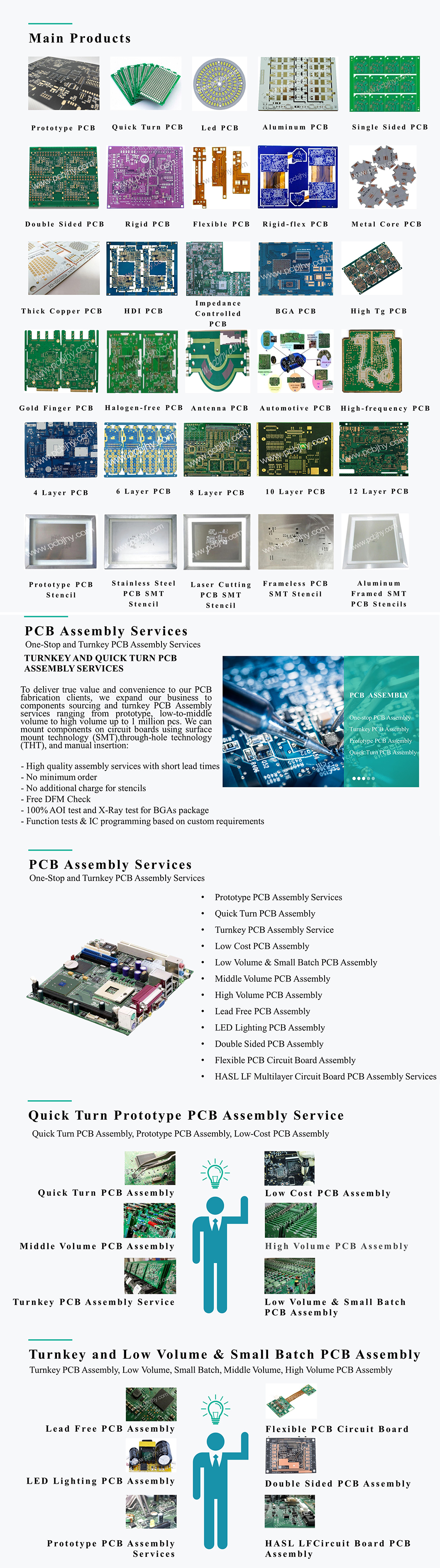

PCB Manufacturing Services

As one of the leading Printed Circuit Board manufacturers based in China, JHYPCB has been offering international companies of all sizes with high-quality PCB prototype to production services at a fair price for 8 years. To make professional and advanced circuit boards, we're committed to adhering to the strictest standards during the PCB manufacturing process, we're fully compliant with the ISO 9001:2008 quality management system.

- A professional and trustworthy PCB Prototype manufacturer.

- Fastest PCB Prototype.

- One-stop solution for various PCB& SMT Stencil.

- Low cost for simple PCB.

- Affordable price for high-tech PCB.

- Minimum orders 1pcs.

- 24-hour online customer service.

- Professional PCB engineer for one-to-one service.

- Shipment on time.

- Guarantee good service and quality from PCB quotation to delivery.

PCB Assembly Services

To deliver true value and convenience to our PCB fabrication clients, we expand our business to components sourcing and turnkey PCB assembly services ranging from the prototype, low-to-middle volume to high volume up to 1 million pcs. We can mount components on circuit boards using surface mount technology (SMT),through-hole technology (THT), and manual insertion:

- No minimum order

- No additional charge for stencils

- Free DFM Check

- 100% AOI test and X-Ray test for BGAs package

- Function tests & IC programming based on custom requirements

All boards are produced according to IPC-6012 standards and inspected according to IPC-A-600 in the latest version. Our products are widely applied in communications, industrial control, power electronics, medical equipment, security electronics, consumer electronics, LED, etc. More than 90 percent of them were exported to Europe, North America, South America.

One-stop Service Include

| PCB Prototype | Quick Turn PCB | Single-Sided PCB |

| Double-Sided PCB | Multilayer PCB | Rigid PCB |

| Flexible PCB | Rigid-Flex PCB | LED PCB |

| Aluminum PCB | Metal Core PCB | Thick Copper PCB |

| HDI PCB | BGA PCB | High TG PCB |

| PCB Stencil | Impedance Control PCB | PCB Assembly |

| High-Frequency PCB | Bluetooth Circuit Board | Automotive PCB |

| USB Circuit Board | Halogen-Free PCB | Antenna PCB |

FAQ

Q1: What service do you have?

A: We are the factory, we have our PCB manufacturing & Assembly factory.

We can offer a one-stop service from PCB manufacturing to PCB assembling, testing, housing, and other value-added services.

Q2: What is your minimum order quantity?

A: Our MOQ is 1 PCS.

Q3. Shipping cost?

A: The shipping cost is determined by the destination, weight, packing size of the goods. Please let us know if you need us to quote you the shipping cost.

Q4: Are my PCB files safe when I submit them to you for manufacturing?

A: We respect customer's copyright and will never manufacture PCB for someone else with your files unless we receive written. Permission from you, nor we'll share these files with any other 3rd parties.

Q5: No PCB file/Gerber file, only have the PCB sample, can you produce it for me?

A: Yes, we could help you to clone the PCB. Just send the sample PCB to us, we could clone the PCB design and work out it.

Q6: How to get the PCBs?

A: For small packages, we will ship the boards to you by DHL, UPS, FedEx, EMS. Door to door service! You will get your PCBs at your home.

For bulky goods more than 300kg, we may ship your PC boards by ship or by air to save freight costs. Of course, if you have your forwarder, we may contact them for dealing with your shipment.

Q7. How about the delivery?

Usually, for sample order, our delivery is about five days. For small-batch, our delivery is about seven days.

For the mass production batch, our delivery is about ten days.

But that depends on the real condition when we get your order.

If your order is urgent, please contact us directly, we will make a priority to deal with it and do our best to give you a satisfied delivery time.

Q8: How about your factory production capacity?

A: we can provide 40000 square meter/month.

Q9: Which countries have you worked with?

A: US, Canada, Italy, Germany, Czech Republic, Australia, Japan, Spain, Portugal, France, Britain, Poland, Ukraine, Russia, Brazil, Argentina, and so on.

Q10: How do you ensure the final quality of the product

For PCB, we will use the Flying Probe Test, E-test, etc. for it.

For PCBA, we need you to offer us a method or test fixture for the function test. Before that, our inspectors will use a microscope and X-ray to check the IC foot welding or bad solder, etc.

Q11: Will you check my files before production?

A: Yes, our engineer will check your Gerber file and BOM list to avoid any mistake.

Q12: My budget is limited; can you provide solutions to save cost?

A: Yes, we can. For example, for PCBA: Replace the DIP components with SMD components, so it can narrow the PCB board size to save cost. Re-layout the PCB to reduce the size, it can save cost. Also, we can recommend alternative components.

Q13: Can we visit your company?

No problem. You are welcome to visit us in Shenzhen.

Related Keywords