Carbide turning inserts for metal lathe

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000 pcs/month |

| Supply Ability: | 10000 pcs/month |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| Certificate: | ISO9000 |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekou,Chiwan |

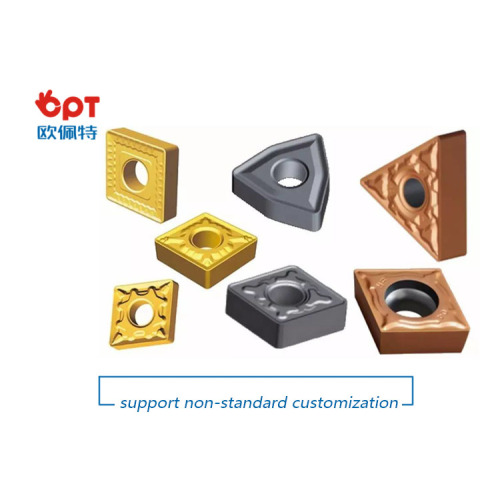

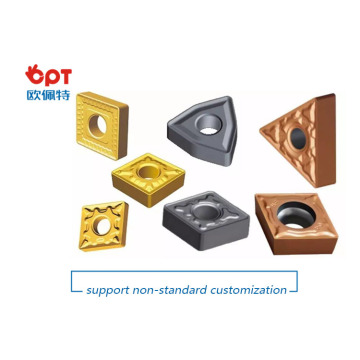

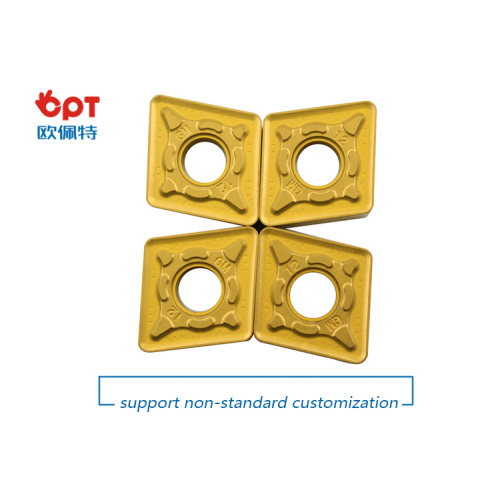

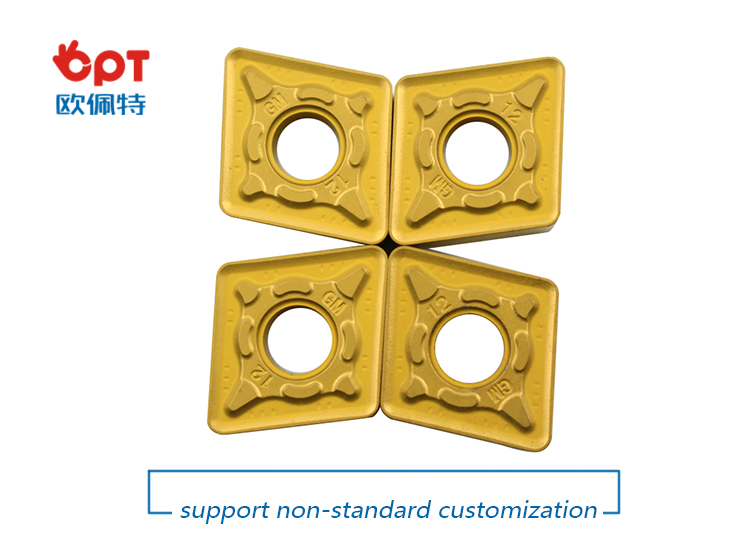

Carbide turning inserts for metal lathe

Related research literature indicates that when cutting at higher cutting speeds, the tool is prone to hot cracking and the edge chipping phenomenon increases. the mechanism of cracking of cemented carbide tools during interrupted cutting is analyzed by cutting test. It is found that during the heating phase of the cutting cycle, the compressive thermal stress can cause local plasticity of the blade along the narrow zone of the rake face of the cutting edge.

Then when the narrow zone is forced to cool again under the influence of the external elastic material, a tensile stress sufficient to cause visible cracks is generated, thereby verifying that thermal stress is the main cause of cracking of the cemented carbide tool.

Advantages:

1. Imported raw powder material.

2. Have a peculiar gradient cobalt-rich on surface of the substrates which can ensure the inserts` high performance when finishing the CVD coating.

3. The coating which have high abrasion resistance. After special management on the surface of the coating inserts, the internal stress and surface of coating were reduced while cutting resistance was also cut down.

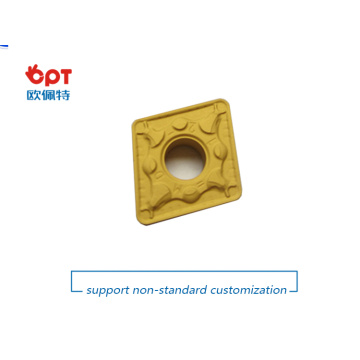

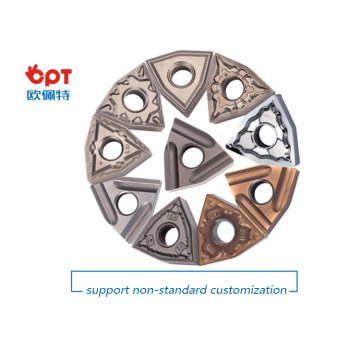

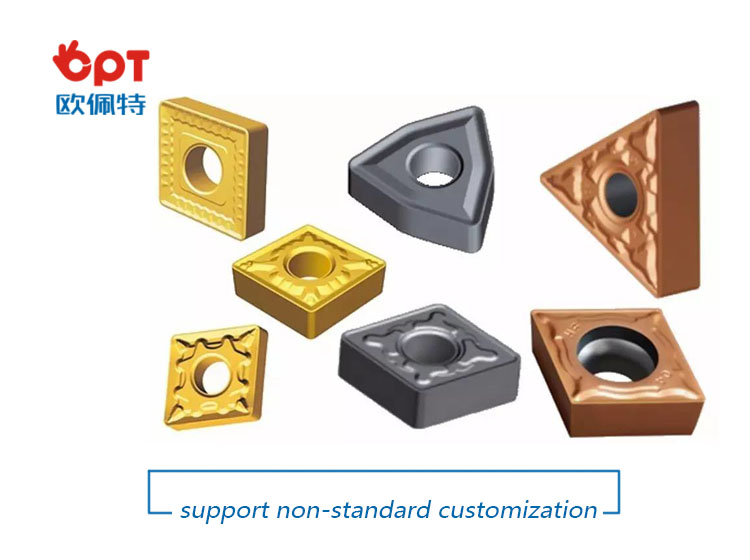

Product Show:

Material:

Tungsten Carbide

Packaging:

Be packed with plastic case or box.

Quality control:

We have dedicated team of quality control and art equipment to keep good and stable performance for our products.

OEM/ODM Service:

Customization cutting tools is an easy process when partnering with OPT. From drawing to tooling completion takes no longer than 4 weeks. With a sample profile, a CAD file or a dimensioned sketch, we design precision profile tooling with safety, accuracy, exceptional performance and our customer`s complete satisfaction in mind.

Our Service:

- sample is available for testing before ordering

- Customer oriented

- After sale replace service

- Full stock available for urgent demands

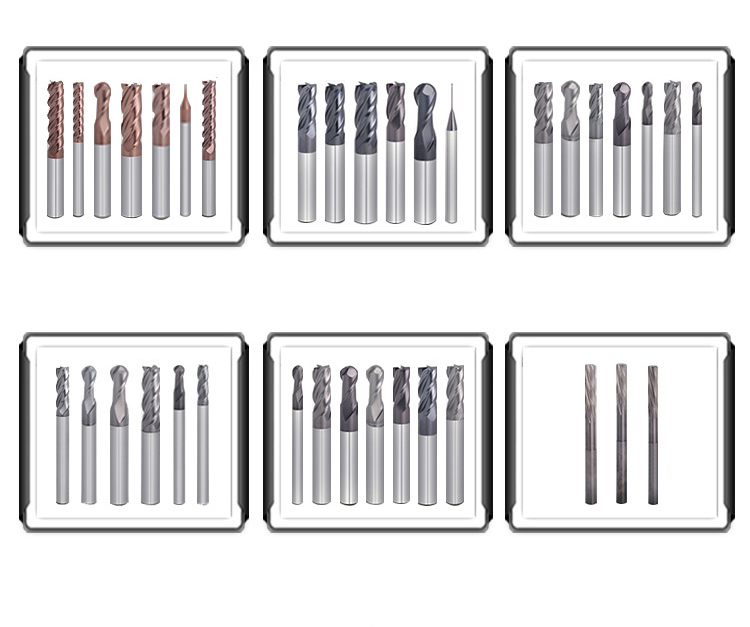

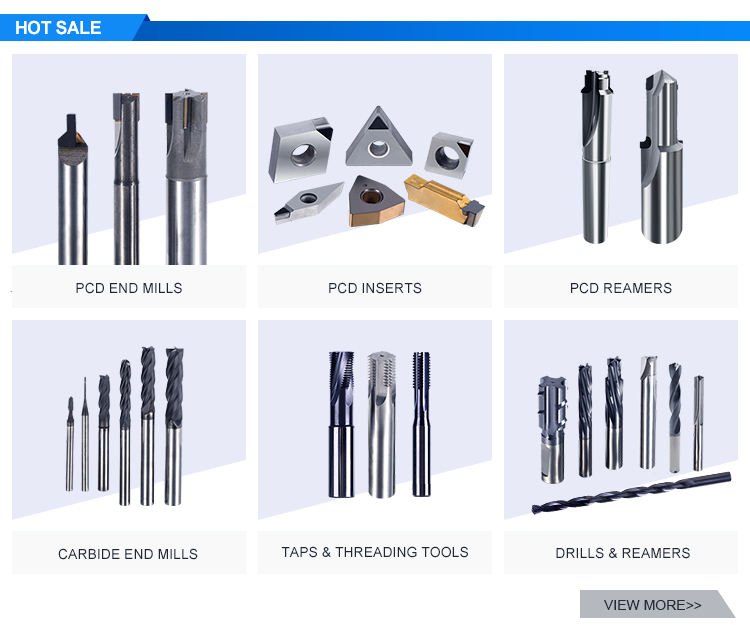

Related products:

Carbide Reamers>>

Carbide Reamers>>

Carbide Cutting Tools>>

Carbide Cutting Tools>>

ABOUT US :

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reamers, Carbide Taps etc.,

We offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords