PCD tipped reamer Diamond reamer bit

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 2 Piece/Pieces

- Min. Order:

- 2 Piece/Pieces

- Delivery Time:

- 15 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Shenzhen, Hongkong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 5000 pcs/month |

| Supply Ability: | 5000 pcs/month |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen,Hongkong |

PCD tipped reamer Diamond reamer bit

More and more automotive gearboxes are made of die-cast aluminum alloys with complex shapes. There are many stepped shaped holes on the gearboxes, which are especially suitable for machining with high efficiency and high precision PCD step reamers.

Made-to-order PCD reamer is a specialty of OPT. OPT is able to supply customer with high-performance PCD tools in a very short lead time. All brazed blanks are kept in stock and are finish-ground to the hole dimensions, tolerances and first-cut geometries defined by the customer in order.

Application:

For aluminium and non-ferrous metal

Automobiles and motorcycles parts: plugs, cylinders, wheels, gearboxes, pump bodies, intake pipes, various housing parts, etc.

Features:

1. The reamer is designed for the processing of nozzle hole, with unique chip discharging slot and internal cooling setting; It can not only satisfy the hole size accuracy and smoothness, but also ensure the coaxiality between the holes.

2. If the tool is designed with internal cooling, it is conducive to the discharge of chips.

Advantage :

Extremely high cutting parameters reduce production cycle and therefore lower total cost, and the tool has a long tool life, which further reduces total machining costs.

Recommended cutting parameters:

n=5000~10000RPM fn=0.3-0.5mm/rev

Product Show:

Check out also: PCD step reamer PCD drilling reamer PCD conbination reamer

Releated Products:

Material:

The PCD tools are

used premium quality diamond material, we choose

the right grade of PCD according the different working

condition.

Packaging:

Be packed with plastic case or box.

Quality control:

We have dedicated team of quality control and art equipment to keep good

and stable performance for our products.

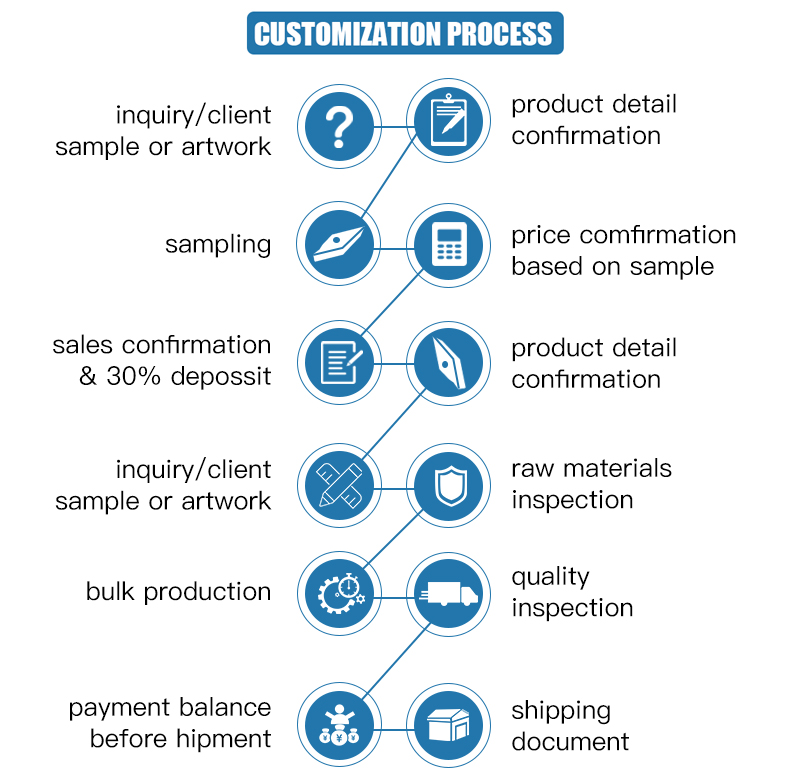

OEM/ODM Service:

Customization cutting

tools is an easy process when partnering with OPT. From drawing to tooling

completion takes no longer than 4 weeks. With a sample profile, a CAD file or a

dimensioned sketch, we design precision profile tooling with safety, accuracy,

exceptional performance and our customer`s complete satisfaction in mind.

Our Service:

- sample is available for testing before ordering

- Customer oriented

- After sale replace service

- Full stock available for urgent demands

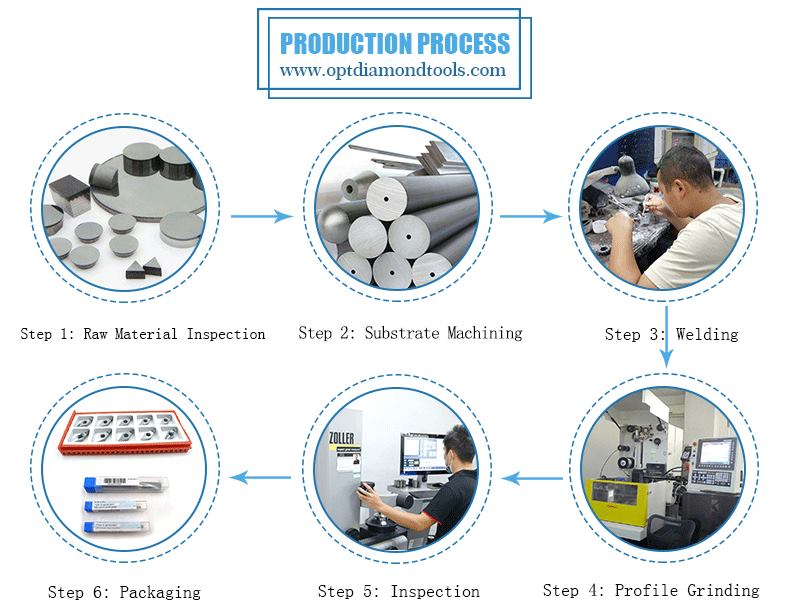

Production Process:

We are specialized PCD diamond tools manufacture. We supply a comprehensive range of PCD diamond cutting tools for woodworking.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Reamers, PCD Forming tools, PCD Woodworking Tools, Carbide Taps, and many more.

If you encounter problems such as high-speed, high precision requirements, low tool life and so on in the processing, you may contact us to recommend appropriate design for you, we can provide customization per your drawing.

Customization Process:

Related Keywords