UN thread milling cutter for carbide

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000month/pieces |

| Supply Ability: | 10000month / pieces |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekou,Chiwan |

UN thread milling cutter for carbide

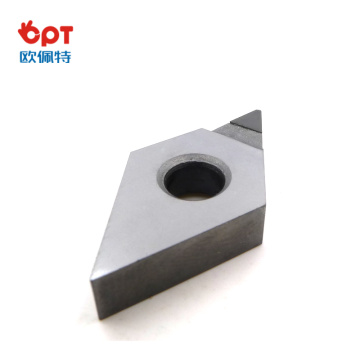

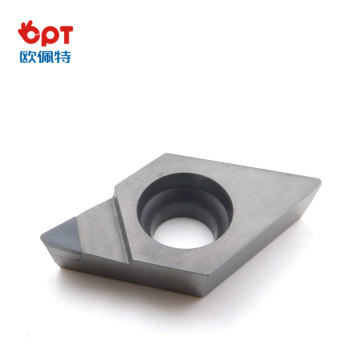

Grinding inserts are made of fine grain cemented carbide with TiN or TiAlN coating available. The design of the front and rear corners of the blade allows it to withstand a large chip load per tooth; the design of the blade shape enables free cutting, reduces radial cutting pressure, and ensures thread machining accuracy. Each blade has 4 usable cutting edges for longer blade life. Precisely machined high-precision tool holders on the steel end face of the tool body ensure precise positioning of the blade.

Development and application of thread milling cutters:

Since the current thread milling cutter is made of cemented carbide or other special alloys, the processing line speed can reach 80-200m/min, and the processing speed of high-speed steel cone is only 10~30m/min, so the thread milling cutter is suitable for high speed. The surface finish of the machined and machined threads is also greatly improved. Threading of high-hardness materials and high-temperature alloy materials, such as titanium alloys and nickel-based alloys, has always been a difficult problem, mainly because high-speed steel wire cones have a shorter tool life when machining the above-mentioned material threads, and use hard alloy thread milling. Knives for hard material threading are an ideal solution. The machinable hardness is HRC 58-62. For threading of superalloy materials, thread milling cutters also exhibit excellent processing performance and an unexpectedly long life. For threaded holes of the same pitch and different diameters, it takes a lot of tools to complete the tapping, but if you use a thread milling cutter, you can use a tool. After the tap wear and the thread size of the thread are less than the tolerance, it can not be used continuously, and can only be scrapped; when the thread milling cutter is worn and the threaded hole size is smaller than the tolerance, the necessary tool radius compensation adjustment can be performed by the numerical control system to continue. Threads of acceptable size are machined. Similarly, in order to obtain high-precision threaded holes, it is much easier to use a thread milling cutter to adjust the tool radius than to produce high-precision taps.

ADVANTAGE:

1. short production times

2.high degree of process safety. very good surface quality

3.combination of different machining jobs with one tool. usable thread depth down to the very bottom of the hole. no expensive lubricants are needed

4. no chip problems, since only short milling chips are created.

5.no axial miscutting (overcut) of the thread

6.universal use in the most different materials up to approx. 60 HRC. blind hole and through hole threads produced with one tool. thread production independent of thread size and tolerance. one tool only for right-hand and left-hand threads. low cutting forces

7.suitable also for thin-wall components

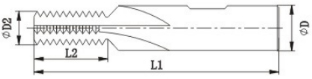

| Size | Dimension | Depth of thread | Model No. | ||||

| mm | Min. Dia. | D | D2 | L1 | L2 | mm | External thread milling |

| 0.6 | M3 | 6 | 5.9 | 58 | 15 | 0.31 | ZZ06059-W0.5ISO |

| 0.75 | M4.5 | 8 | 7.9 | 64 | 19.5 | 0.46 | ZZ08079-W0.75ISO |

| 1 | M6 | 10 | 9.9 | 73 | 24 | 0.61 | ZZ10099-W1.0ISO |

| 1.6 | M 10 | 12 | 11.9 | 84 | 30 | 0.92 | ZZ12119-W1.5ISO |

| 2 | M 14 | 12 | 11.9 | 84 | 30 | 1.23 | ZZ12119-W2.0ISO |

| 3 | M24 | 16 | 15.9 | 93 | 36 | 1.84 | ZZ16159-W3.0ISO |

| 4 | M36 | 16 | 15.9 | 93 | 40 | 2.45 | ZZ16159-W4.0ISO |

| 6 | M64 | 20 | 19.9 | 106 | 36 | 3.68 | ZZ20199-W6.0ISO |

| Size | Dimension | Depth of thread | Model No. | ||||

| tpi | Min.Dia. | D | D2 | L1 | L2 | mm | External thread milling |

| 32 | No. 6 | 6 | 5.9 | 57 | 14.3 | 0.49 | ZZ06059-W32UN |

| 28 | No. 12 | 8 | 7.9 | 63 | 19.9 | 0.56 | ZZ08079-W28UN |

| 20 | 1/4" | 10 | 9.9 | 72 | 22.9 | 0.78 | ZZ10099-W20UN |

| 18 | 5/16" | 10 | 9.9 | 72 | 24 | 0.87 | ZZ10099-W18UN |

| 16 | 3/8" | 12 | 11.9 | 83 | 28.6 | 0.97 | ZZ12119-W16UN |

| 12 | 9/16" | 12 | 11.9 | 83 | 29.6 | 1.3 | ZZ12119-W12UN |

| 8 | 1" | 16 | 15.9 | 92 | 38.1 | 1.95 | ZZ16159-W8UN |

| 6 | 13/8" | 20 | 19.9 | 104 | 38.1 | 2.6 | ZZ20199-W6UN |

ABOUT US :

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords