Solide carbide UNF UNC thread milling cutters

- Payment Type:

- L/C, T/T, D/P, Western Union

- Incoterm:

- FOB, CFR, CIF, FCA

- Min. Order:

- 10 Piece/Pieces

- Min. Order:

- 10 Piece/Pieces

- Delivery Time:

- 30 Days

- Transportation:

- Ocean, Land, Air

- Port:

- Yantian, Shekou, Chiwan

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000month/pieces |

| Supply Ability: | 10000month / pieces |

| Payment Type: | L/C,T/T,D/P,Western Union |

| Incoterm: | FOB,CFR,CIF,FCA |

| HS Code: | 108040399 |

| Transportation: | Ocean,Land,Air |

| Port: | Yantian,Shekou,Chiwan |

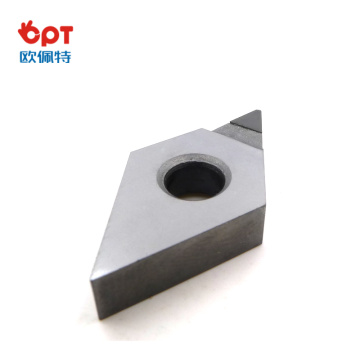

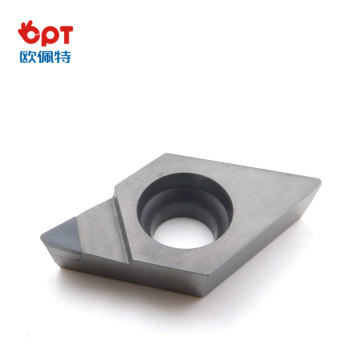

Carbide UNF UNC thread milling cutters

The advantages of thread milling cutters in the machining of high frequency molds are:

Since the thread milling cutter can perform large-depth knife cutting during roughing, this not only improves the processing efficiency, but also improves the service life of the tool. The main reason is that the cutting amount is distributed due to the depth of the knife. The side edge of the tool also reduces the number of times the bottom edge is machined (the bottom surface that needs to be machined twice becomes one).

The thread milling cutter has a small wear and can be used for tens of hours of continuous operation in the roughing of the high frequency die (59 copper) using a thread milling cutter with "double edge, 2 mm diameter and 3 mm blade length". Due to the small wear during processing, the size of the machining residue is relatively accurate, which can effectively ensure the smooth progress of the finishing process. For the above reasons, thread milling cutters are called [professional roughing tools", so learners should be trained to use [thread milling cutters for roughing".

For the thread that does not allow the transition buckle or the undercut structure, the traditional turning method or taps and die are difficult to machine, but it is very easy to realize by CNC milling. In addition, the durability of the thread milling cutter is ten or even ten times that of the tap, and in the process of numerically milling the thread, the adjustment of the thread diameter size is extremely convenient, which is difficult to achieve by using taps and die. Due to the many advantages of thread milling, the milling process has been widely used in large-scale thread production in developed countries.

ADVANTAGE:

1.is not afraid of breaking, after the wire breaks and breaks, the workpiece may be scrapped. The thread milling cutter is easy to take out even if it is broken manually, and the workpiece will not be scrapped.

2.thread milling cutters are much more efficient than wire tapping.

3. blind hole thread milling cutter can be milled to the bottom, wire tapping is not possible.

4. For some materials, thread milling cutters can be drilled. Milling teeth. Once chamfered, the wire tapping is not possible.

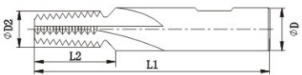

| Size | Dimension | Depth of thread | Model NO. | |||||

| tpi | Min. Dia. | D | D2 | L1 | L2 | mm | ||

| 27 | 1/16" | 6 | 5.9 | 57 | 9.41 | 0.66 | ZZ06059-WN27NPT | |

| 18 | 1/4" | 8 | 7.9 | 63 | 14.11 | 1.01 | ZZ08079-WN18NPT | |

| 14 | 1/2" | 12 | 11.9 | 83 | 19.96 | 1.33 | ZZ12119-WN14NPT | |

| 11.5 | 1" | 16 | 15.9 | 92 | 26.51 | 1.64 | ZZ16159-WN11.5NP | |

| 8 | 2 1/2" | 16 | 15.9 | 92 | 38.1 | 2.42 | ZZ16159-WN8NPT | |

ABOUT US :

We are specialize in manufacturing PCD diamond tools and Carbide tools. Our major product inclulde PCD inserts, PCD Reamers, PCD End Mills, PCD Taps, Cabide Inserts,Carbide Drills, Carbide Reams, Taps etc.,

We also offered customized cutting tools per drawings, and provide package according to customer requirements. We manufacture a series range of cutting tools for machining of Cast iron, Aluminium alloy and Non-Ferros metal, it is widely used in all major sectors like Automobiles, Engineering, Aerospace, Aviation and 3C industry. Premium quality of raw material is used in the production and strict examination during processing with advanced equipment, so our client are satisfied with our reliable quality and on-time delivery.

Our best selling of cutting tools include PCD Inserts, PCD End Mill, PCD Ball Nose Mill, PCD Reamer, Carbide Taps, Carbide End Mill, Special Form Cutter and many more. For these years we have been made a large forward in the technologies of manufacturing cutting tools. With high quality on performance and price, our product sells well both on domestic and overseas market. And we will always focus on the quality and best service, to make long business relationship.

Related Keywords