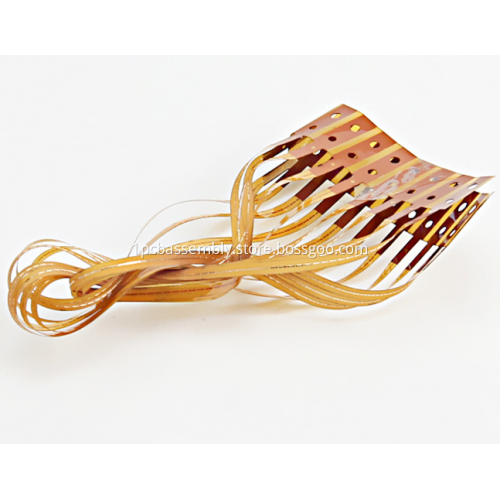

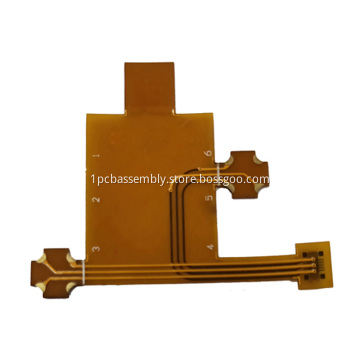

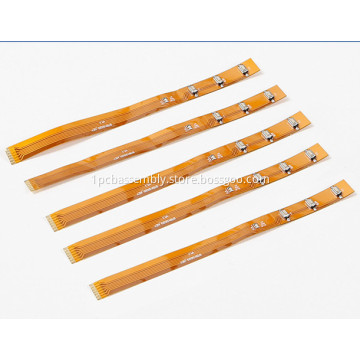

Multilayer Flex / Flexible Printed Circuits (FPC) Board

- Payment Type:

- T/T, Paypal, Money Gram, Western Union

- Incoterm:

- FOB, CFR, CIF

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 5-30 Days

- Transportation:

- Ocean, Land, Air, UPS

- Port:

- Shenzhen, HongKong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Shenzhen China |

|---|---|

| Productivity: | 500,000pcs per Month |

| Supply Ability: | 500,000pcs per Month |

| Payment Type: | T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF |

| Certificate: | ISO9001, IATF16949, IPC-A-610F |

| HS Code: | 8517709000 |

| Transportation: | Ocean,Land,Air,UPS |

| Port: | Shenzhen,HongKong |

Multilayer Flex / Flexible Printed Circuits (FPC) Board

Multilayer flex circuits

Flex circuits having three or more layers of conductors are known as multilayer flex circuits. Commonly the layers are interconnected by means of plated through holes, though this is not a requirement of the definition for it is possible to provide openings to access lower circuit level features. The layers of the multilayer flex circuit may or may not be continuously laminated together throughout the construction with the obvious exception of the areas occupied by plated through-holes. The practice of discontinuous lamination is common in cases where maximum flexibility is required. This is accomplished by leaving unbonded the areas where flexing or bending is to occur.

Flexible circuits electronics, also known as flex circuits, is a technology for assembling electronic circuits by mounting electronic devices on flexible plastic substrates, such as polyimide, PEEK or transparent conductive polyester film. Additionally, flex circuits can be screen printed silver circuits on polyester. Flexible electronic assemblies may be manufactured using identical components used for rigid printed circuit boards, allowing the board to conform to a desired shape, or to flex during its use. An alternative approach to flexible electronics suggests various etching techniques to thin down the traditional silicon substrate to few tens of micrometers to gain reasonable flexibility, referred to as flexible silicon (~ 5 mm bending radius).

Advantage of FPCs

Potential to replace multiple rigid boards or connectors

Single-sided circuits are ideal for dynamic or high-flex applications

Stacked FPCs in various configurations

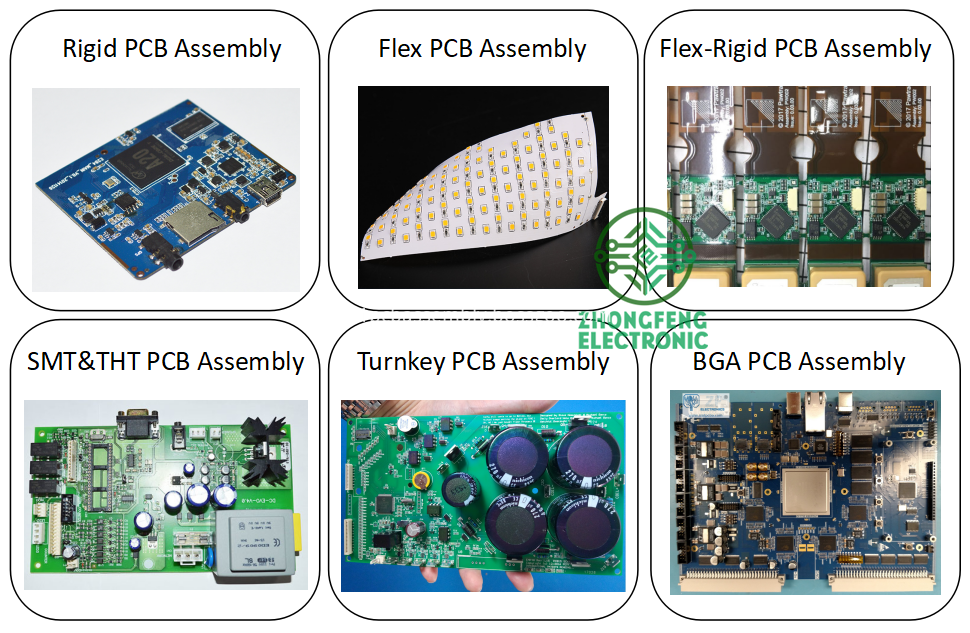

Our Services:

1. PCB Design: One-stop EMS manufacturer, speciallized in designing wireless charging PCBA, bluetooth earphone & Voice box PCBA and other consumer electronics products.

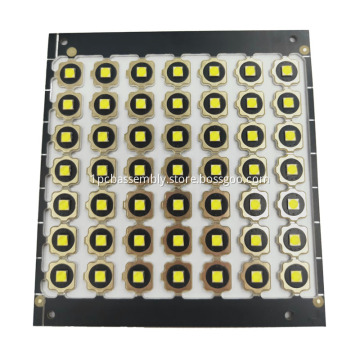

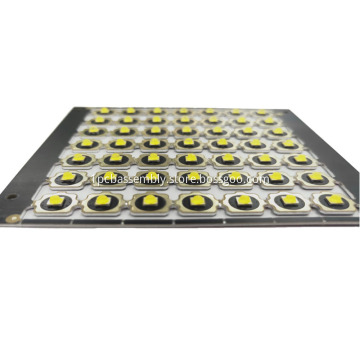

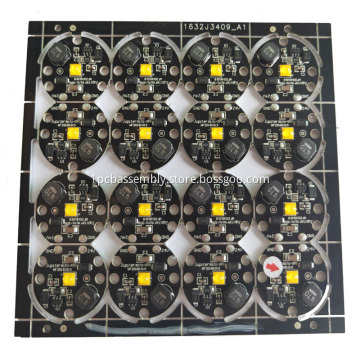

2. PCB Manufacture: Standard FR4 1-36layer PCB, Flex PCB, Rigid-Flex PCB, HDI PCB, Rogers PCB, Metal Core PCB, etc.

3. PCB Assembly: SMT and THT assembly, available for 01005, fine pitch and BGA assembly.

4. Components Sourcing: Available to source all components shown in BOM file (BOM Kitting), hard to find components and long lead time components, etc.

5. One-Stop Turnkey PCBA Manufacture: PCB design+PCB Manufacture+Components Sourcing+PCB Assembly+Electronic Assembly, or PCB Manufacture+Components sourcing+PCB Assembly, etc.

Technical Capabilities:

|

PCB Manufacture Capabilities |

|

|

Layers |

1-36 layers |

|

Material |

FR-4 (Standard FR4, Mid-Tg FR4, Hi-Tg FR4, Lead free assembly material) , Polymide, Metal Core, Rogers, etc. |

|

Board Thickness |

0.1mm-6.0mm (.016"-.126") |

|

Copper Thickness |

1/2oz-6oz(18um-210um) |

|

Board size |

600mm*1200mm |

|

Min Tracing/Spacing |

0.075mm/0.075mm (3mil/3mil) |

|

Min drilling Hole diameter |

0.15mm(6mil), 0.1mm(4mil)-laser drill |

|

Solder Mask |

LPI, different colors(Green, Green matt, Black, Black Matt, White, Red, Yellow, Blue) |

|

Silkscreen color |

White, Blue, Black, Red, Yellow |

|

Surface finish |

Lead free HASL, immersion gold, golden finger, immersion tin, immersion silver, OSP, Carbon oil, plated hard gold(up to 100u") |

|

Impedance tolerance |

+/-5%~+/-10% |

|

Chamfer of Gold Fingers |

20, 30, 45, 60 |

|

Test |

Flying probe or Testing fixture |

|

PCB Assembly Capabilities |

|

|

Quantity |

From prototype to big volume, no MOQ |

|

Assembly type |

SMT, THT or Hybrid |

|

Parts procurement |

Full turnkey (we provided all components) |

|

Partial turnkey ( Customer provide the main components and we provide the rest) |

|

|

Kitted (Customer provide all components) |

|

|

Component types |

SMT 01005, BGA 0.3mm pitch, QFP 0.3mm pitch, etc. |

|

Test |

Custom testing, ICT, FCT, AOI, Test jig |

Our Team and Office:

Our PCB Manufacture Factory:

Our PCB Assembly Factory:

FAQ:

Q: What files need for custom PCB manufacture?

A: Gerber or .pcb or .pcbdoc or .brd file is required.

Q: What files need for custom PCB assembly order?

A: Gerber and the BOM files are required, if you have pick&place file, send it to us as well.

Q: What is payment terms acceptable?

A: For new customer and the total amount within 10000usd, 100% payment in advance by PayPal or T/T or WU. For total amount beyond 10000usd, please contact us.

Q: What files need for PCB/PCBA clone services?

A: For PCB/PCBA clone service, send us the pictures for evaluate first, and we will need 1-2 samples of the PCB/PCBA board for copying.

Related Keywords