How to Cut HDPE Sheet For Water Tank

- Transportation:

- Ocean, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000 Ton/month |

| Supply Ability: | 3000 Ton/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | SGS/TUV/ISO:2015 |

| Transportation: | Ocean,Air |

| Port: | Shenzhen |

How to Cut HDPE Sheet For Water Tank

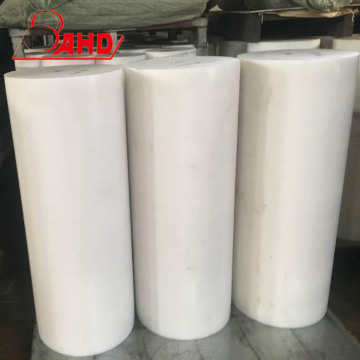

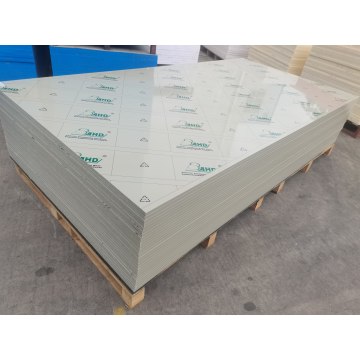

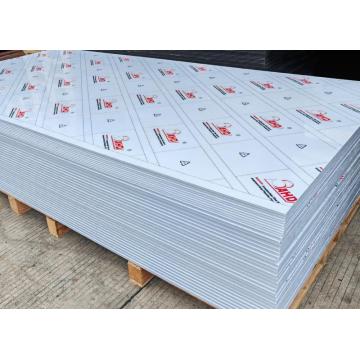

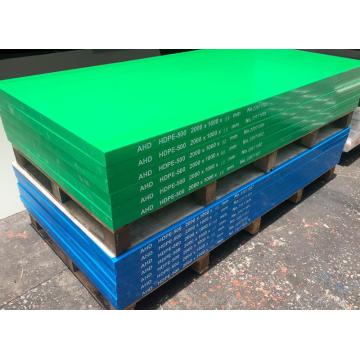

HDPE board (high density polyethylene board) has a relative density of 0.96 g / cm 3 and a melting point of 120 ° C. PE board has the characteristics of high toughness, tensile strength and good abrasion resistance. It has excellent resistance to most household and industrial chemicals. High Density Polyethylene Sheet Hdpe is not hygroscopic. Anheda produces boards with good quality and low price, which is your best partner.

Characteristics:

The Hdpe Polythene Sheet is made of polyethylene plastic pellets. It has excellent sound absorption and separation, resistance to water vapor permeability and gas shutoff, low water absorption and low thermal conductivity.

Areas of use

Hdpe Plastic Sheets Medical appliance parts, seals, cutting boards, sliding profiles. Widely used in chemical, mechanical, chemical, electric power, clothing, packaging, food and other industries. Widely used in gas transportation, water supply, sewage, agricultural irrigation, mine fine particle solids transportation, as well as oilfield, chemical and postal communication, etc., especially in gas transportation has been widely used.

Tolerance & Weight Sheet of HDPE Sheet:

Hdpe 500 Sheet Physical Datesheet:

|

Item |

HDPE Sheet |

|

Color: |

White/ Black/Colorful |

|

Proportion: |

0.96g/cm³ |

|

Heat resistance (continuous): |

90℃ |

|

Heat resistance (short-term): |

110 |

|

Melting point: |

120℃ |

|

Glass transition temperature: |

_ |

|

Linear thermal expansion coefficient (average 23~100℃): |

155×10-6m/(m.k) |

|

Flammability(UI94): |

HB |

|

(Dipping into water at 23℃: |

0.0001 |

|

Bending tensile stress/ Tensile stress off shock: |

30/-Mpa |

|

Tensile modulus of elasticity: |

900MPa |

|

Compressive stress of normal strain-1%/2%: |

3/-MPa |

|

Friction coefficient: |

0.3 |

|

Rockwell hardness: |

62 |

|

Dielectric strength: |

>50 |

|

Volume resistance: |

1015Ω×cm |

|

Surface resistance: |

1016Ω |

|

Relative dielectric constant-100HZ/1MHz: |

2.4/- |

|

Bonding capacity: |

0 |

|

Food contact: |

+ |

|

Acid resistance: |

+ |

|

Alkali resistance |

+ |

|

Carbonated water resistance: |

+ |

|

Aromatic compound resistance: |

0 |

|

Ketone resistance: |

+ |

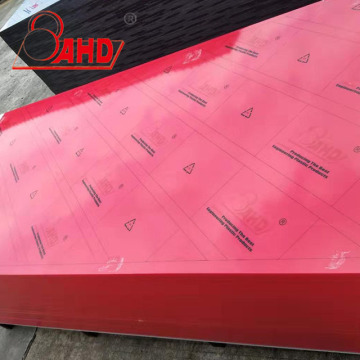

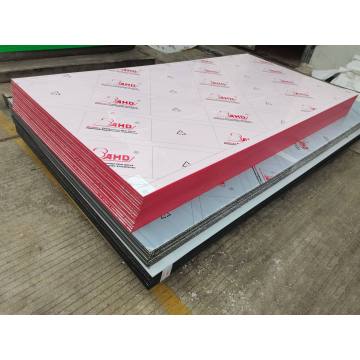

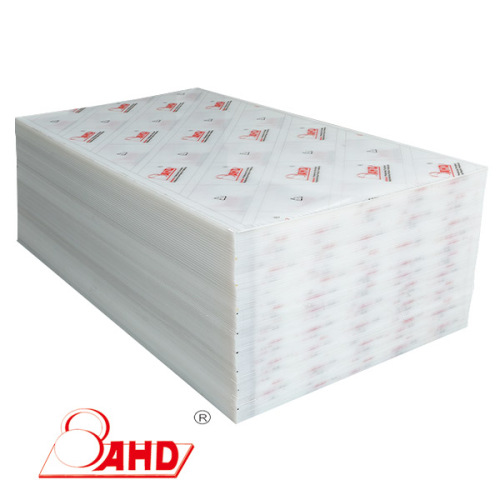

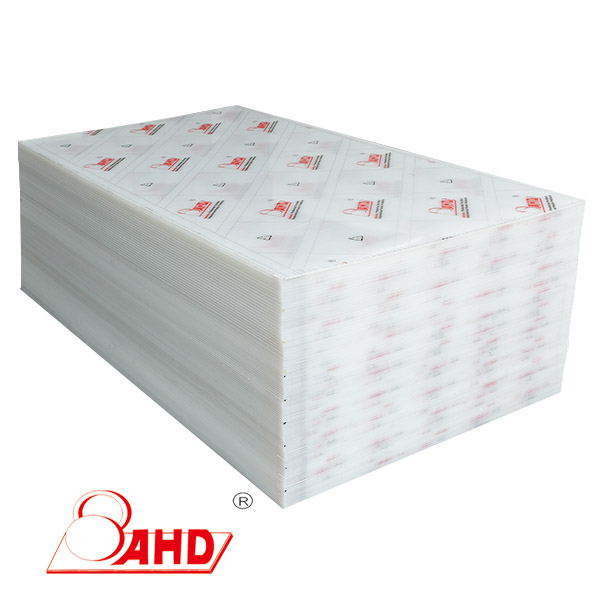

Plastic Hdpe Sheet Photos:

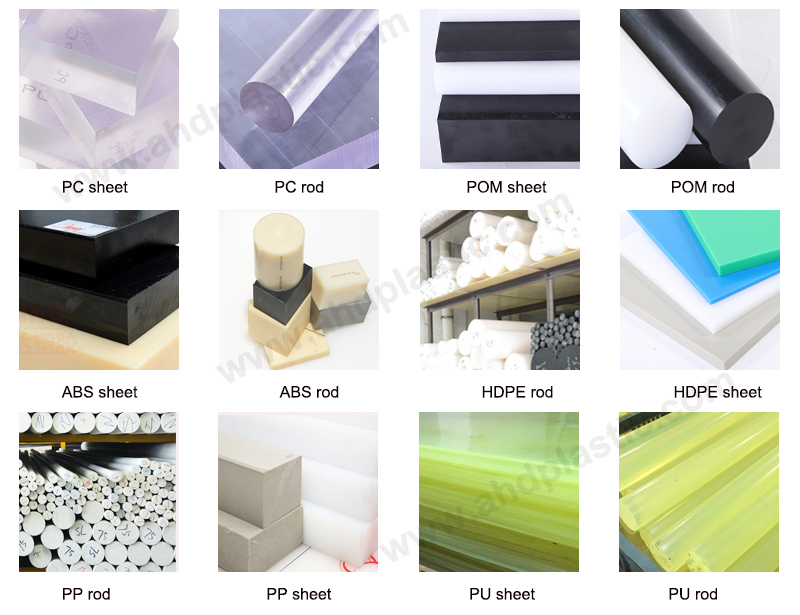

AHD Plastic also provide other semi-finished engineering plastic (like below):

Our service:

1. Quotation reply: Answered within 24h.

2. MOQ: For general size, MOQ can be 100KGS.If you need to customize products, MOQ is 1000KGS of each specification.

3. Sample: samples can be sent free, you just need pay for express fee.

4. Mixed batch: Support mixed batch.

5. After sales service: Your satisfaction is our final goal. You can always get a solution from us when you have questions after receiving the goods.

Customers Visit:

FAQ:

Q1: Are you a manufacturer?

A1: Yes, AHD the the semi-finished engineering plastic products manufacturer in Shenzhen China since 1994s. Our main goods include [POM, HDPE, PP, PU, PA6, ABS, POM+GF, ESD POM, PA6+GF" sheet & rod.

Q2:How do I know your quality?

A2: Free sample will be able to verify our quality.

Q3: What`s payment?

A3: T/T,L/C,Western Union etc. About the payment details please feel free to contact free to contact us.Thank you!

Q4:Can you supply sample?

A4:Yes,we can supply you free small samples,but air cost will be paid by customers.

Q5:How many days will the samples be finished?And how about the mass production?

A5: Generally the samples will be sent immediately by the air express in 1--3 days, the leading time mass production is depended on the stock status and sizes.

Related Keywords