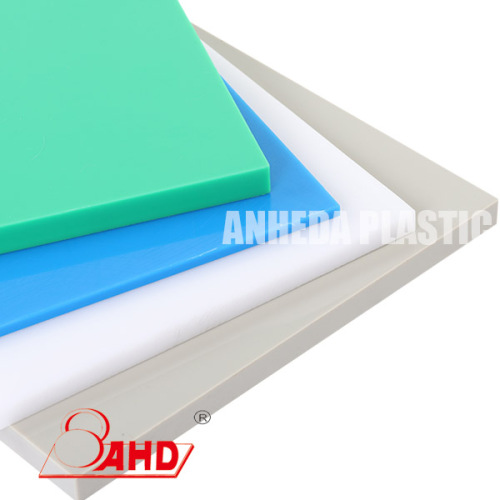

High Density Polyethylene HDPE PE Sheets

- Transportation:

- Ocean

- Port:

- Guangdong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000 Ton/month |

| Supply Ability: | 3000 Ton/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | SGS/TUV/ISO:2015 |

| Transportation: | Ocean |

| Port: | Guangdong |

HDPE (Hdpe Polythene Sheet) is a semi-crystalline, thermoplastic engineering material that is formed into a plastic sheet by extrusion, calendering, cooling, cutting, and removal of internal stress. It has good heat resistance and cold resistance, and chemical stability. Good, high rigidity and toughness, good mechanical strength, good dielectric properties and environmental stress crack resistance.

Hdpe 500 Sheet Main Properties:

stable physical properties, anti-aging, low density, good electrical and dielectric insulation, low water absorption, non-toxic and harmless. Anheda's HDPE sheet can reach food grade and have corresponding quality inspection reports.

500 Micron Hdpe Sheet Application:

Drinking water sewage pipes, hot water pipes, transportation containers, pump and valve parts, medical appliance parts, seals, cutting boards, sliding profiles.

Specification:

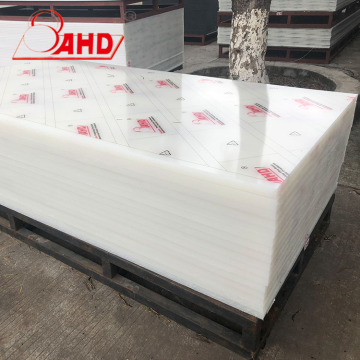

|

Item name |

HDPE sheet |

|

Type: |

extruded |

|

Size: |

1000*2000mm or 1220*2440mm |

|

Thickness: |

1---200mm |

|

Density: |

0.96 g/cm³ |

|

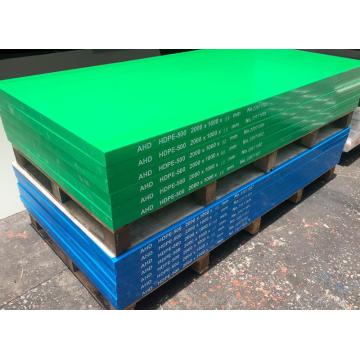

Color: |

White / black / blue / green / yellow |

|

Brand name: |

AHD |

|

Material: |

100% virgin material |

|

Sample: |

FREE |

|

Food Contact |

YES |

Plastic HDPE Sheet Physical Datasheet:

|

Item |

polythene sheet |

|

Color: |

White,Black,Colored |

|

Proportion: |

0.96g/cm³ |

|

Heat resistance (continuous): |

80℃ |

|

Heat resistance (short-term): |

100 |

|

Melting point: |

170℃ |

|

Glass transition temperature: |

_ |

|

Linear thermal expansion coefficient (average 23~100℃): |

155×10-6m/(m.k) |

|

Flammability(UI94): |

HB |

|

(Dipping into water at 23℃: |

0.0001 |

|

Bending tensile stress/ Tensile stress off shock: |

30/-Mpa |

|

Tensile modulus of elasticity: |

900MPa |

|

Compressive stress of normal strain-1%/2%: |

3/-MPa |

|

Friction coefficient: |

0.3 |

|

Rockwell hardness: |

62 |

|

Dielectric strength: |

˃50 |

|

Volume resistance: |

1015Ω×cm |

|

Surface resistance: |

1016Ω |

|

Relative dielectric constant-100HZ/1MHz: |

2.4/- |

|

Bonding capacity: |

0 |

|

Food contact: |

+ |

|

Acid resistance: |

+ |

|

Alkali resistance |

+ |

|

Carbonated water resistance: |

+ |

|

Aromatic compound resistance: |

0 |

|

Ketone resistance: |

+ |

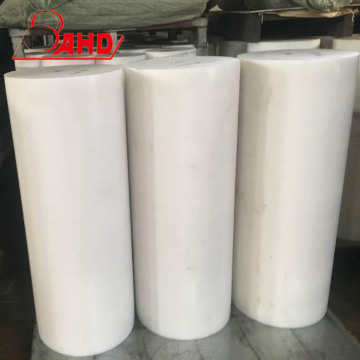

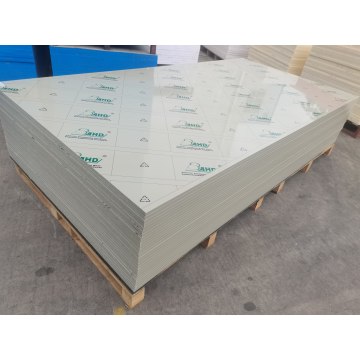

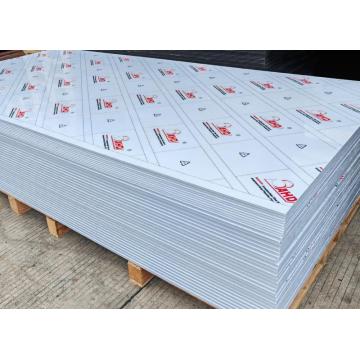

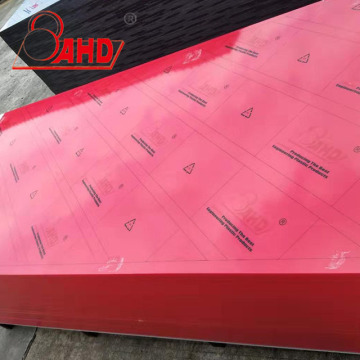

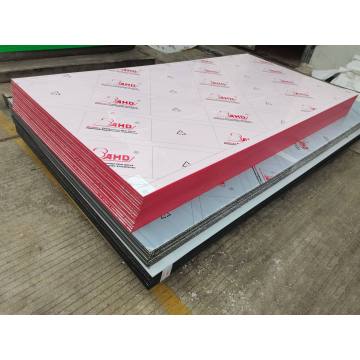

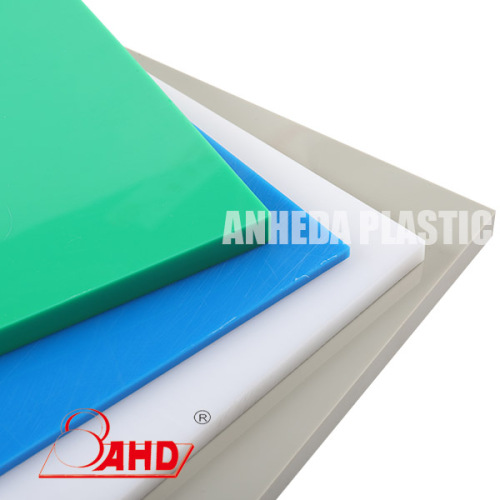

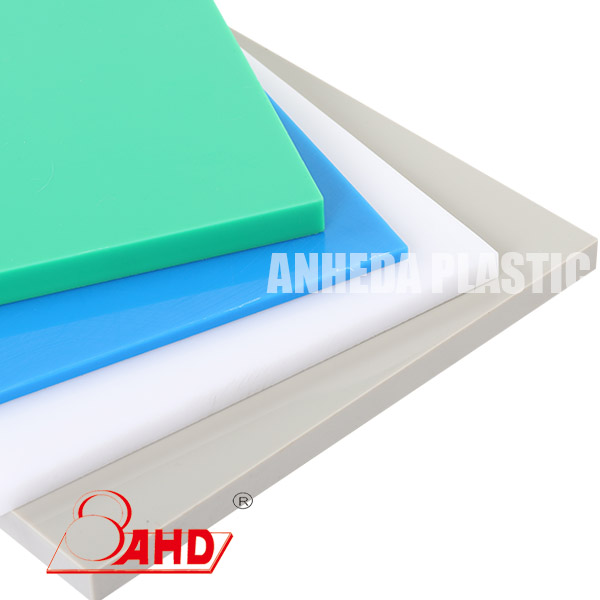

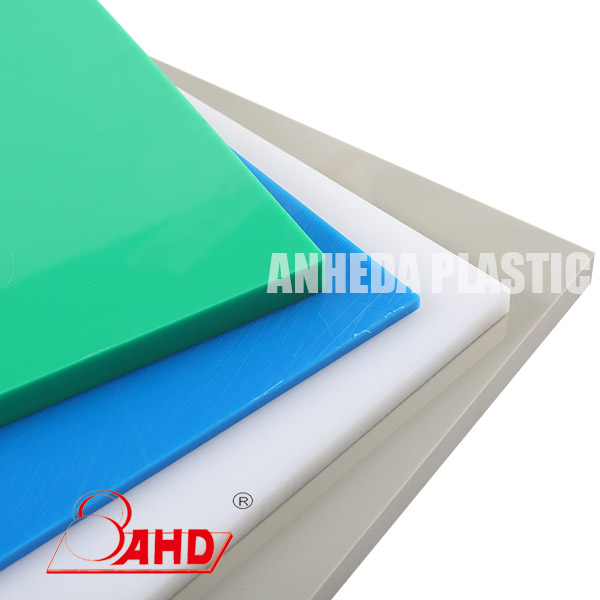

Polyethylene Sheet Goods Photo:

Certification:

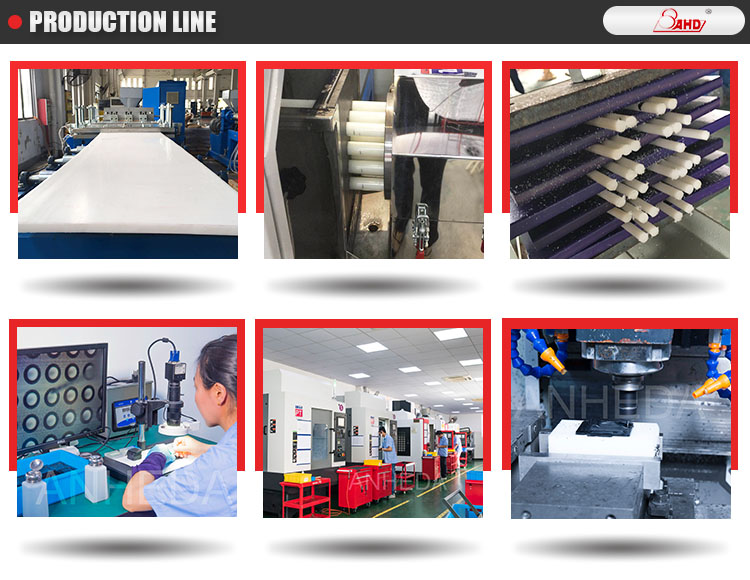

Production Line:

Exhibition:

Anheda group is invited to participate in domestic and international trade exhibitions every year as the most representative exhibitor,has widely attracted the attention of customers from all over the world.It making anheda group play more loudly, spread farther and have wider influence.

FAQ:

Q1: Are you a factory or trade company?

A1: we are a manufacturter for semi-finished engineering plastic sheet & rod like "

Polypropylene Plastic Sheet,Nylon Sheet,Pa6 Rod,Abs Plastic Sheet,Abs Plastic Sheet ,PP Rod and Sheet, POM Sheet, PC Sheet"etc since 1994.

Q2: Is your sample free?

A2:Yes, our samples are free, but the shipping cost is paid by the buyer.

Q3: What about the MOQ ?

A3:In addition to the sample, the minimum order quantity for a regular size product is 100kgs.

Q4: What about the packing ?

A4: As per factory's exported standard, usually use steel pallets.

Q5: What about the payment term ?

A5:we accept payment by L/C , T/T, usually 30% deposit is requested before production. 50% deposit is request for customzied items.

Q6: What's your delivery time?

A6:For samples: within 1-3 working days; For orders: within 7-30 working days.

Related Keywords