Wear resistant Low Temperature Resistance HDPE Sheet

- Transportation:

- Ocean

- Port:

- Guangdong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000 Ton/month |

| Supply Ability: | 3000 Ton/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | SGS/TUV/ISO:2015 |

| Transportation: | Ocean |

| Port: | Guangdong |

Wear resistant Low Temperature Resistance HDPE Sheet

The HDPE sheet and Plastic Hdpe Sheet of Anheda Plastic have good chemical stability. The operating temperature of Anheda's PE sheet can be from -40 to 80 degrees, cold resistance and low temperature resistance. Hdpe Polythene Sheet is resistant to most acids, alkalis, organic solutions and hot water.

Main Properties:

1, excellent self-lubricating, very low friction coefficient. When working with sliding or rotating, it is lubricated than steel brass and lubricating oil.

2, excellent chemical resistance, in addition to strong fluorinated acid, corrosion resistance (acid, alkali, salt) and organic medium in a certain temperature and concentration range.

3, the water absorption rate is low, so generally no drying treatment is required before the molding process.

4, impact energy absorption, impact energy absorption value is good, with excellent noise reduction effect, low noise during work.

5, non-toxic, tasteless, no exudate. Access to food and medicine.

6, antistatic, good flame retardancy, radiation protection

Hdpe 300 Plastic Sheet Application:

Widely used in gas transportation, water supply, sewage, agricultural irrigation, mine fine particle solids transportation, as well as oilfield, chemical and postal communication, etc., especially in gas transportation has been widely used.

Extruded Pe Sheet Specification:

|

Item name |

HDPE sheet |

|

Type: |

extruded |

|

Size: |

1000*2000mm or 1220*2440mm |

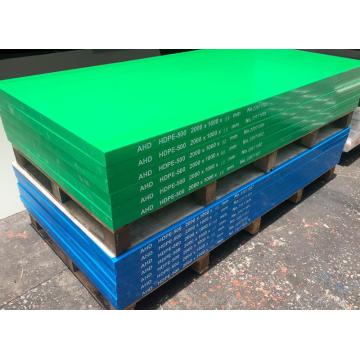

|

Thickness: |

1---200mm |

|

Density: |

0.96 g/cm³ |

|

Color: |

White / black / blue / green / yellow |

|

Brand name: |

AHD |

|

Material: |

100% virgin material |

|

Sample: |

FREE |

|

Food Contact |

YES |

Plastic HDPE Sheet Physical Datasheet:

|

Item |

polythene sheet |

|

Color: |

White,Black,Colored |

|

Proportion: |

0.96g/cm³ |

|

Heat resistance (continuous): |

80℃ |

|

Heat resistance (short-term): |

100 |

|

Melting point: |

170℃ |

|

Glass transition temperature: |

_ |

|

Linear thermal expansion coefficient (average 23~100℃): |

155×10-6m/(m.k) |

|

Flammability(UI94): |

HB |

|

(Dipping into water at 23℃: |

0.0001 |

|

Bending tensile stress/ Tensile stress off shock: |

30/-Mpa |

|

Tensile modulus of elasticity: |

900MPa |

|

Compressive stress of normal strain-1%/2%: |

3/-MPa |

|

Friction coefficient: |

0.3 |

|

Rockwell hardness: |

62 |

|

Dielectric strength: |

˃50 |

|

Volume resistance: |

1015Ω×cm |

|

Surface resistance: |

1016Ω |

|

Relative dielectric constant-100HZ/1MHz: |

2.4/- |

|

Bonding capacity: |

0 |

|

Food contact: |

+ |

|

Acid resistance: |

+ |

|

Alkali resistance |

+ |

|

Carbonated water resistance: |

+ |

|

Aromatic compound resistance: |

0 |

|

Ketone resistance: |

+ |

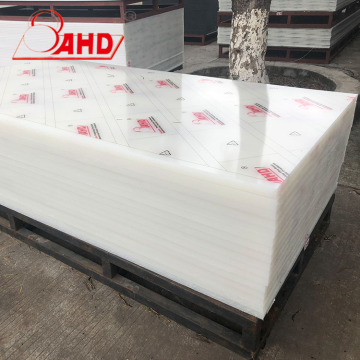

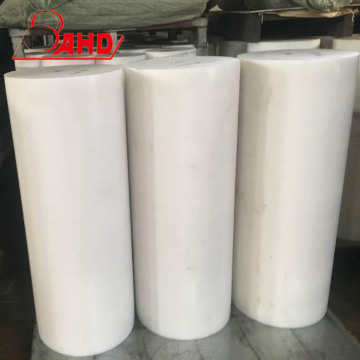

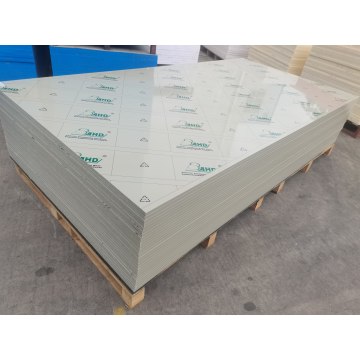

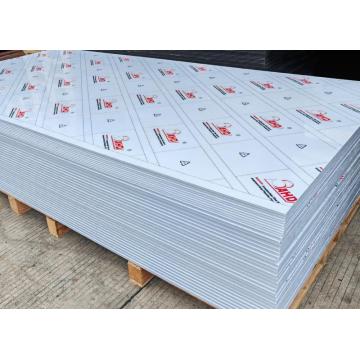

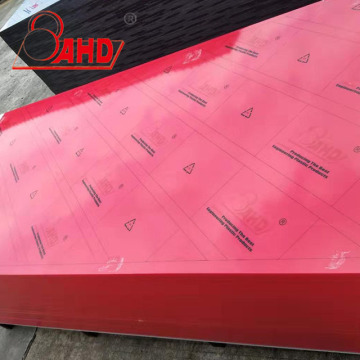

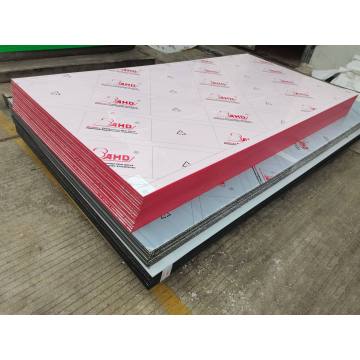

Polyethylene Sheet Goods Photo:

Certification:

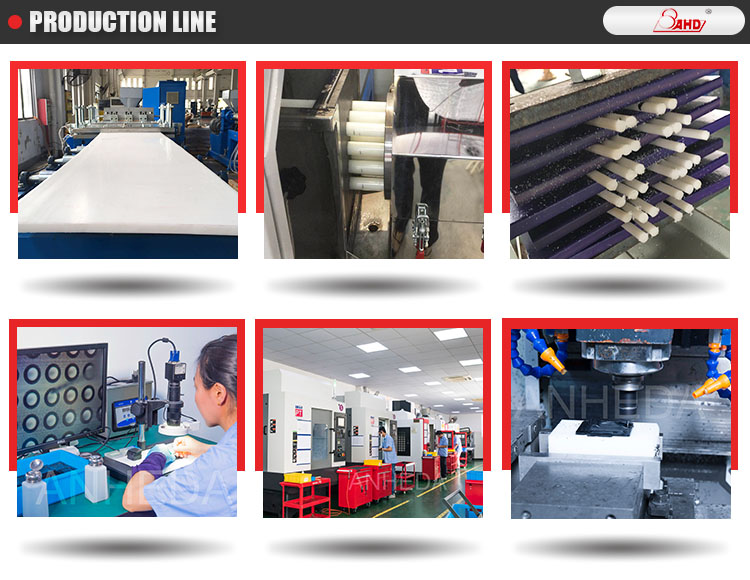

Production Line:

Exhibition:

Anheda group is invited to participate in domestic and international trade exhibitions every year as the most representative exhibitor,has widely attracted the attention of customers from all over the world.It making anheda group play more loudly, spread farther and have wider influence.

FAQ:

Q1: Are you a manufacturer?

A1: Yes, AHD the the semi-finished engineering plastic products manufacturer in Shenzhen China since 1994s. Our main goods include [POM, HDPE, PP, PU, PA6, ABS, POM+GF, ESD POM, PA6+GF" sheet & rod.

Q2:How do I know your quality?

A2: Free sample will be able to verify our quality.

Q3: What`s payment?

A3: T/T,L/C,Western Union etc. About the payment details please feel free to contact free to contact us.Thank you!

Q4:Can you supply sample?

A4:Yes,we can supply you free small samples,but air cost will be paid by customers.

Q5:How many days will the samples be finished?And how about the mass production?

A5: Generally the samples will be sent immediately by the air express in 1--3 days, the leading time mass production is depended on the stock status and sizes

Related Keywords