Thin Thick PE HDPE Polyethylene Plastic Sheet Board

- Transportation:

- Ocean

- Port:

- Guangdong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000 Ton/month |

| Supply Ability: | 3000 Ton/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | SGS/TUV/ISO:2015 |

| Transportation: | Ocean |

| Port: | Guangdong |

Thin Thick PE HDPE Polyethylene Plastic Sheet Board

Hdpe Polythene Sheet: Full name is High Density Polyethylene Sheet. Plastic Hdpe 300 Sheet is a high crystallinity, non-polar thermoplastic resin. The appearance of the original HDPE was milky white and was somewhat translucent in a thin section. The water absorption of this material is less than 0.01, does not absorb water, has good water resistance, is often used in the packaging food industry, and has good chemical stability.

HDPE has very good electrical properties, especially high insulation dielectric strength, which makes it very suitable for wire and cable. Medium to high molecular weight grades have excellent impact resistance, even at room temperature and even at low temperatures of -40F. The unique characteristic of this grade of HDPE is the proper combination of several basic variables: density, molecular weight, molecular weight distribution and additives. Different catalysts are used to produce custom polymers with special properties. These variables combine to produce HDPE grades for different uses; achieving the best balance in performance. Has good chemical stability, can resist most acids, alkalis, organic solutions and hot water erosion, good electrical insulation.

Application of HDPE 500 sheet:

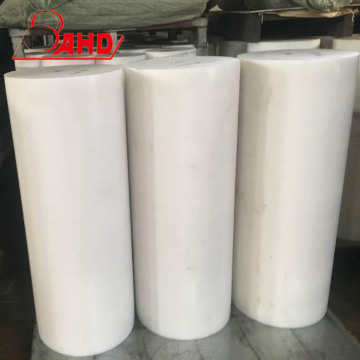

HDPE boards and PE boards produced by rods are produced using imported equipment and unique internal stress relief technology, and use new PE raw materials without adding any recycled materials. After years of unremitting innovation and improvement, the bottom cut has eliminated problems such as plate deformation, air bubbles, and easy fracture. It has good heat resistance and cold resistance, good chemical stability, high rigidity and built-in, and good mechanical strength. Dielectric properties and resistance to environmental stress cracking are also better. At the same time, suitable pressurization and processing aids are also very important product applications: medical device parts, seals, cutting boards, sliding profiles. Widely used in chemical, machinery, chemical, power, clothing, packaging, food and other industries. Widely used in gas transportation, water supply, sewage, agricultural irrigation, mine fine particle solids transportation, and conventional, chemical and post and telecommunications fields, especially in gas transportation has been widely used.

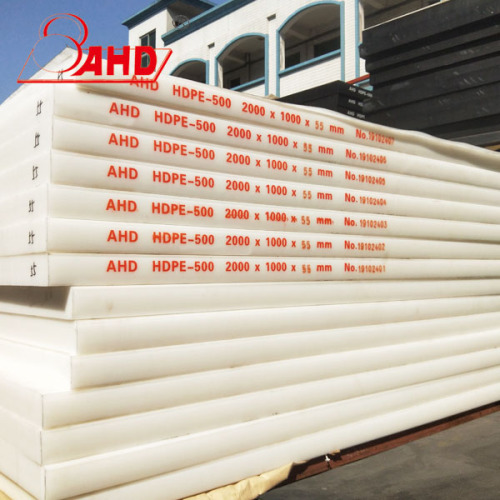

Specification:

|

Item name |

HDPE sheet |

|

Type: |

extruded |

|

Size: |

1000*2000mm or 1220*2440mm |

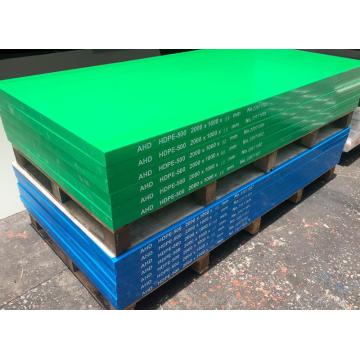

|

Thickness: |

1---200mm |

|

Density: |

0.96 g/cm³ |

|

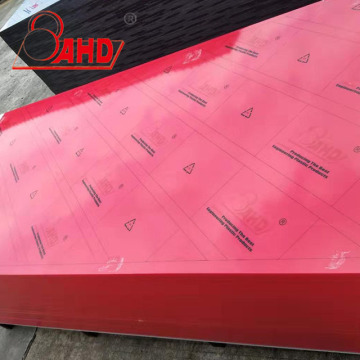

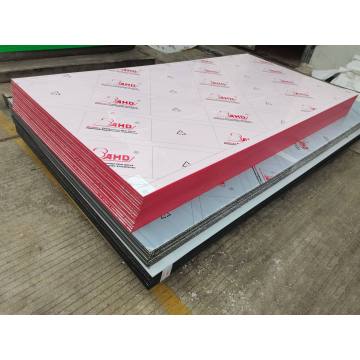

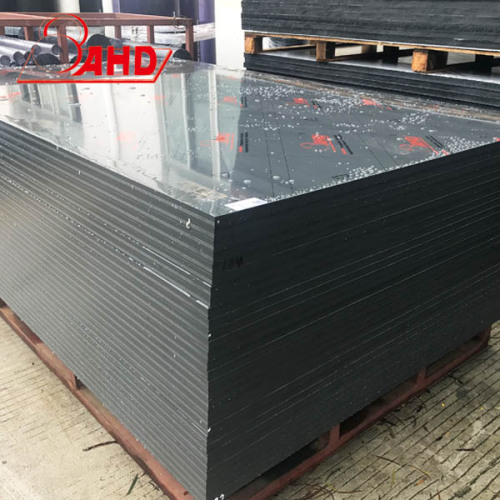

Color: |

White / black / blue / green / yellow |

|

Brand name: |

AHD |

|

Material: |

100% virgin material |

|

Sample: |

FREE |

|

Food Contact |

YES |

Plastic HDPE Sheet Physical Datasheet:

|

Item |

polythene sheet |

|

Color: |

White,Black,Colored |

|

Proportion: |

0.96g/cm³ |

|

Heat resistance (continuous): |

80℃ |

|

Heat resistance (short-term): |

100 |

|

Melting point: |

170℃ |

|

Glass transition temperature: |

_ |

|

Linear thermal expansion coefficient (average 23~100℃): |

155×10-6m/(m.k) |

|

Flammability(UI94): |

HB |

|

(Dipping into water at 23℃: |

0.0001 |

|

Bending tensile stress/ Tensile stress off shock: |

30/-Mpa |

|

Tensile modulus of elasticity: |

900MPa |

|

Compressive stress of normal strain-1%/2%: |

3/-MPa |

|

Friction coefficient: |

0.3 |

|

Rockwell hardness: |

62 |

|

Dielectric strength: |

˃50 |

|

Volume resistance: |

1015Ω×cm |

|

Surface resistance: |

1016Ω |

|

Relative dielectric constant-100HZ/1MHz: |

2.4/- |

|

Bonding capacity: |

0 |

|

Food contact: |

+ |

|

Acid resistance: |

+ |

|

Alkali resistance |

+ |

|

Carbonated water resistance: |

+ |

|

Aromatic compound resistance: |

0 |

|

Ketone resistance: |

+ |

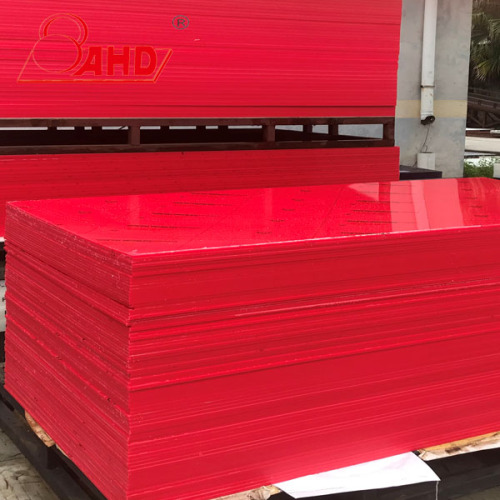

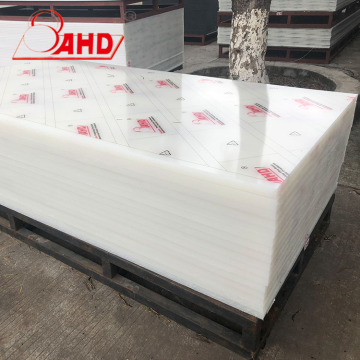

Polyethylene Sheet Goods Photo:

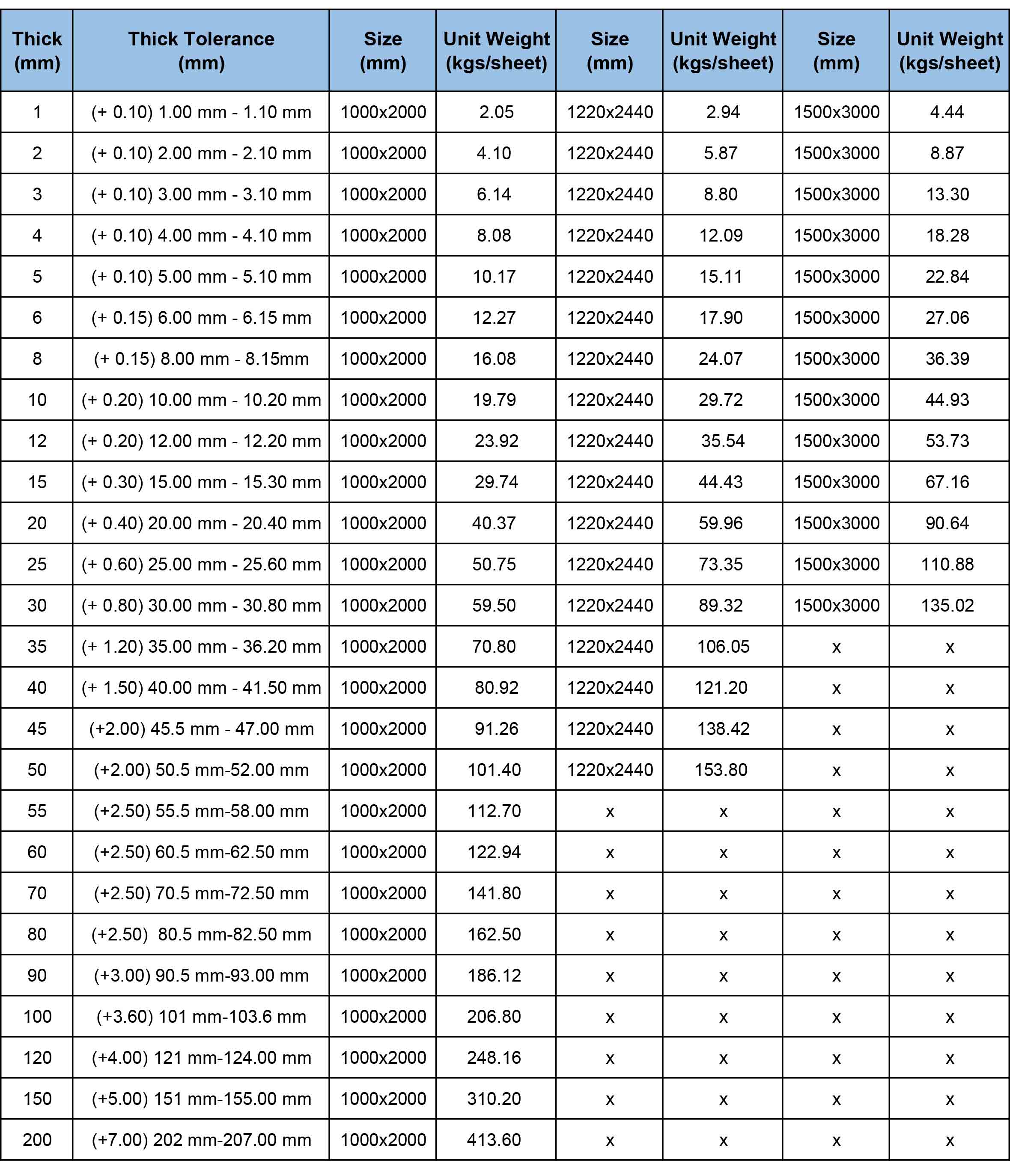

HDPE Sheet Tolerance Reference Sheet:

Plastic Hdpe Sheet Certification:

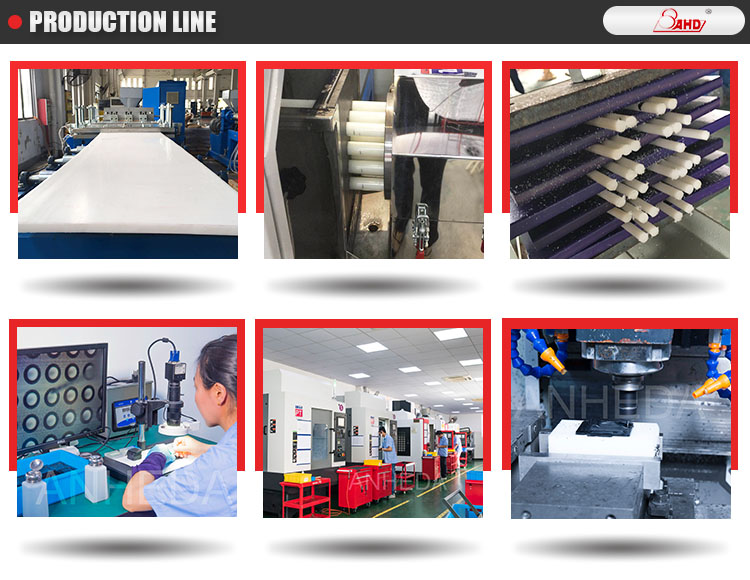

Production Line:

Exhibition:

Anheda group is invited to participate in domestic and international trade exhibitions every year as the most representative exhibitor,has widely attracted the attention of customers from all over the world.It making anheda group play more loudly, spread farther and have wider influence.

FAQ:

Q1: Are you a factory or trade company?

A1: we are a manufacturter for semi-finished engineering plastic sheet & rod like "

Polypropylene Plastic Sheet,Nylon Sheet,Pa6 Rod,Abs Plastic Sheet,Abs Plastic Sheet ,PP Rod and Sheet, POM Sheet, PC Sheet"etc since 1994.

Q2: Is your sample free?

A2:Yes, our samples are free, but the shipping cost is paid by the buyer.

Q3: What about the MOQ ?

A3:In addition to the sample, the minimum order quantity for a regular size product is 100kgs.

Q4: What about the packing ?

A4: As per factory's exported standard, usually use steel pallets.

Q5: What about the payment term ?

A5:we accept payment by L/C , T/T, usually 30% deposit is requested before production. 50% deposit is request for customzied items.

Q6: What's your delivery time?

A6:For samples: within 1-3 working days; For orders: within 7-30 working days.

Related Keywords