Polycarbonate PC Sheets Boards Engraving CNC Machining

- Transportation:

- Ocean, Air

- Port:

- Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000 Ton/month |

| Supply Ability: | 3000 Ton/month |

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | SGS/TUV/ISO:2015 |

| Transportation: | Ocean,Air |

| Port: | Shenzhen |

Polycarbonates can be broadly classified into two broad categories: one is an aromatic polycarbonate, mainly a bisphenol A type polycarbonate, and the other is a rare polycarbonate.

Two types of polycarbonate vary greatly in composition, function and application.

Polycarbonate, which is often said to be an aromatic polycarbonate, is an engineering plastic with excellent induction. It is characterized by transparency, excellent impact strength, heat resistance, dimensional stability and electrical insulation. Then, it is widely used in agriculture, industry, high-tech scale, and everyday days. And continuous development. This thermoplastic engineering plastic has entered everyone's horizons. In the past few years, sun panels made of this material, endurance panels, and u-shaped sun panels. Have been known for everyone. This kind of polycarbonate is recognized by all walks of life and even ordinary people.

Extruded Pc Sheet Features:

Transmittance: good light transmission performance. PC endurance plate transmittance is up to 88%.

Weather resistance: The surface has anti-UV co-extruded layer, which can block the passage of ultraviolet light from the sun, thus making the sheet difficult to age and yellow, and has good weather resistance.

Sound insulation performance: It has good sound insulation performance and can effectively reduce noise. It is the material of choice for highway sound barriers.

Impact resistance: The impact strength of PC endurance board is 250 to 300 times that of ordinary glass of the same thickness, 30 times of acrylic sheet and 2 times of tempered glass. It has the reputation of not broken glass" and is a high-quality material for making bulletproof glass.

Flame retardant: GB GB4-4-2006 test is a flame retardant B1 grade. It will not produce toxic gas when burned. It will self-extinguish from the fire and will not promote the spread of fire.

Temperature resistance: at minus 40 degrees Celsius to 120 degrees Celsius, there will be no deterioration of quality, mechanical and mechanical properties, and other quality deterioration phenomena;

Lightweight: Light weight, endurance plate density is only half of the average glass, thus saving the cost of transportation, handling, installation and support frame, and the plate can be cold-bent, giving the architects a broader design space.

Pc Solid Plastic Rods Applicatiion:

Residential building lighting, canopy, carport, sun room, stadium roof, pool roof, transportation infrastructure, industrial building lighting, mall aisle, hotel atrium, greenhouse, soundproof wall, advertising light box, signage, security, interior decoration, etc.

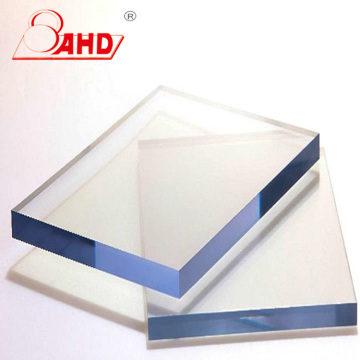

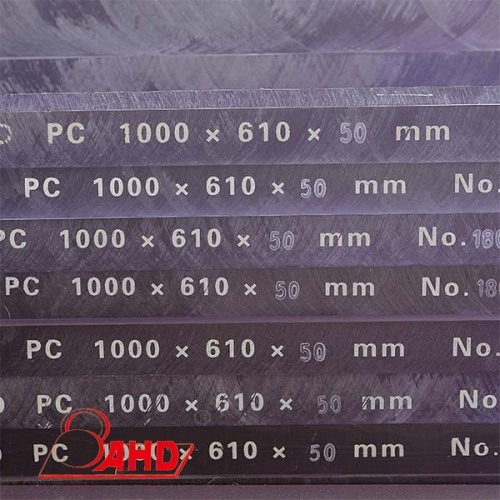

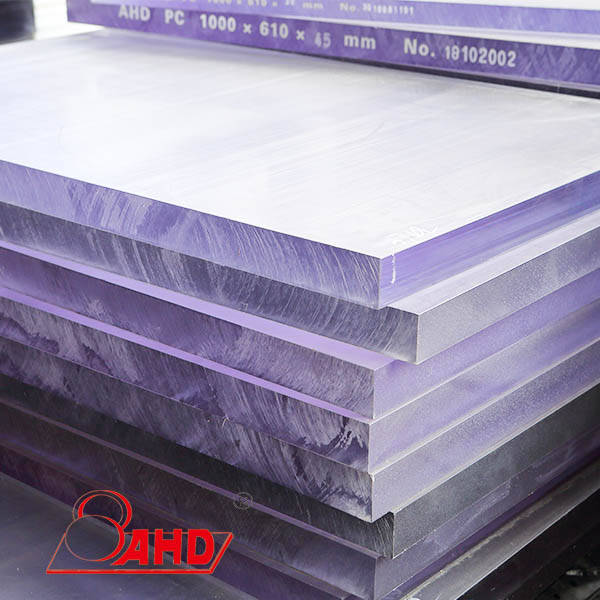

Pc Plastic Rod Specification

|

Item name |

PC ( Polycarbonate) sheet |

|

Type: |

extruded |

|

Size: |

1000*2000mm |

|

Thickness: |

15---200mm |

|

Density: |

1.2 g/cm³ |

|

Color: |

Translucent |

|

Brand name: |

AHD |

|

Material: |

100% virgin material |

|

Sample: |

FREE |

|

Acid resistance: |

YES |

|

Food Contact |

YES |

Physical Datasheet:

|

Item |

PC sheet |

|

Color: |

clear |

|

Proportion: |

1.2g/cm³ |

|

Heat resistance (continuous): |

125℃ |

|

Heat resistance (short-term): |

135℃ |

|

Glass transition temperature: |

150℃ |

|

Linear thermal expansion coefficient (average 23~100℃): |

65×10-6 m/(m.k) |

|

Average 23--150℃ |

65×10-6 m/(m.k) |

|

Flammability(UI94): |

HB |

|

Tensile modulus of elasticity: |

2400MPa |

|

Dipping into water at 23℃ for 24h |

13% |

|

Dipping into water at 23℃ |

0.35% |

|

Bending tensile stress/ Tensile stress off shock |

70/- Mpa |

|

Breaking tensile strain |

˃50% |

|

Compressive stress of normal strain-1%/2%: |

18/35 MPa |

|

Pendulum gap impact test |

9 KJ/m2 |

|

Friction coefficient: |

0.55 |

|

Rockwell hardness: |

M75 |

|

Dielectric strength: |

28 kv/mm |

|

Volume resistance: |

10 15Ω×cm |

|

Surface resistance: |

10 15Ω |

|

Relative dielectric constant-100HZ/1MHz: |

3/3 |

|

Critical tracking index(CTI) |

600 |

|

Bonding capacity: |

+ |

|

Food contact: |

+ |

|

Acid resistance: |

+ |

|

Alkali resistance |

- |

|

Carbonated water resistance: |

0 |

|

Aromatic compound resistance: |

- |

|

Ketone resistance: |

- |

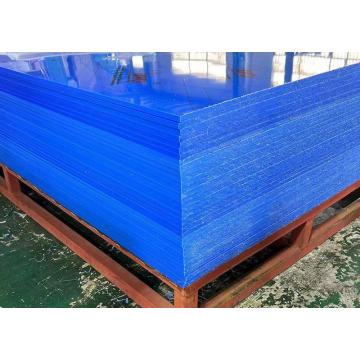

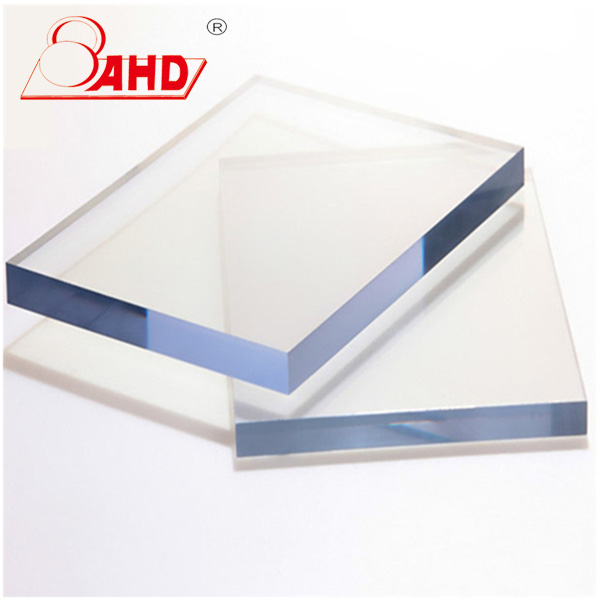

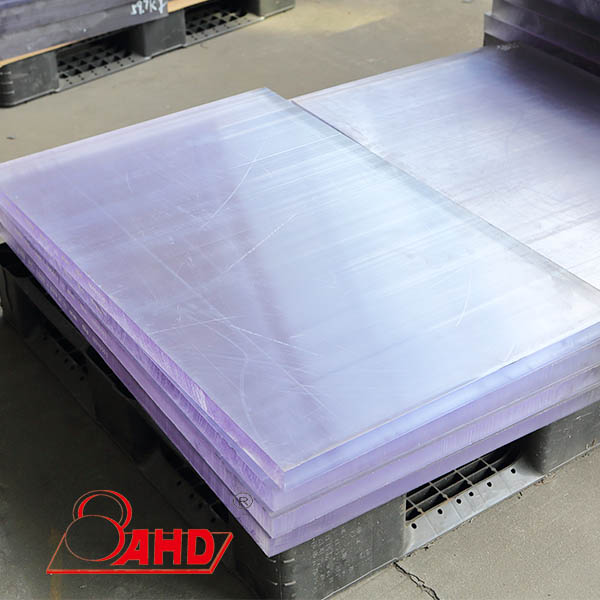

PC Sheet Photo:

Company Profile:

Established in Shenzhen in 1994, our company is a comprehensive company that is engaged in the R&D, production and distribution of semi-finished engineering plastic in China, including POM, PC, ABS, PP, PE, PVC, PA6 and PU sheet & rod. Our company has more than 250 plastic production lines of imported manufacturing equipment, and covers an area of 25000 square meters. With over 200 employees (a number of them are senior engineers), together with many years of experience and customers' feedback, we have been a leader in plastic industry field for the constant perfection of our service network, technical level and product scope.

We've obtained independent import and export rights and established various branches all over the country. Our products sell well in Europe, America and Southeast Asia. The proportion of export has increased over years.

We can meet customers' requirements, and we can find out the best solution for each application. Besides, we can also help our customers to maintain the competitive position and have every customer obtain benefits from the best products.

Exhibition:

As the most representative exhibitor, the Anheda Group is invited to participate in national and international exhibitions every year. At the same time, it has attracted extensive attention from customers all over the world, making the anheda group more famous, spreading farther and more influential.

Related Keywords