Hard Polycarbonate Sheet Sheets Cutting

- Transportation:

- Ocean

- Port:

- Guangdong

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 3000 Ton/month |

| Supply Ability: | 3000 Ton/month |

| Payment Type: | L/C,T/T,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | SGS/TUV/ISO:2015 |

| Transportation: | Ocean |

| Port: | Guangdong |

PC endurance board product introduction:

Polycarbonate sheet (polycarbonate sheet) is called PC board and is excellent in impact resistance and light transmission.

Physical property analysis of pc endurance board:

(1) Mechanical properties

Impact resistance: PC board has strong impact resistance, 250 times stronger than traditional glass and 30 times stronger than acrylic.

Tensile strength: PC board has good heat resistance, so its tensile strength is still 350kgf / cm2 even at 120 °C.

Flexural strength and flexural modulus: PC board has excellent bending resistance and does not crack even when the bending angle is 80-90°.

Anti-fatigue and anti-submarine change: The anti-submarine of PC board becomes one of the best in thermoplastic plastic. Even at high temperature, its latent change is still small, and the stress is steep and small.

(2) Thermal properties

Heat distortion temperature: The heat distortion temperature of the PC board was 135 ° C, and it was continuously used at a high temperature of about 120 ° C.

Linear expansion coefficient: one of synthetic resins having a small linear expansion coefficient.

Embrittlement temperature: The embrittlement temperature of PC is extremely low compared with general plastics, it is -40 °C, and the continuous application of low temperature is about -30 °C.

Flammability: PC board is one of the flame retardant plastics, which does not hit toxic gases when heated at high temperatures.

Heat yield: The heat yield of PC board is not much different from that of general synthetic resin. It is 1/4 of glass, 1/300 of iron, 1/1000 of aluminum and 1/2000 of copper. It is a material with excellent heat preservation. .

(3) Optical properties

Transmittance: The transmission transmittance of a 1 mm thick PC board is 90%, and the transmission transmittance of a 5 mm thick is 85%, so it is suitable for glass.

The company's PC board has a layer of anti-ultraviolet layer on its surface. Even if its optical properties are continuously exposed, the mechanical properties are not significantly affected.

(4) The nature of the sound insulation:

The PC board at the same thickness has a better sound-blocking effect than the momentum.

(5) Weight:

Under the same thickness and area, the weight of the PC board is half that of the glass, which can save a lot of difficulty and freight for handling and construction.

PC board engineering plastics application areas:

1. Building materials industry

Polycarbonate sheet has good light transmission, impact resistance, UV radiation resistance and dimensional stability of the product and good molding processability, and has obvious technical performance advantages compared with the inorganic glass traditionally used in the construction industry.

2. Automotive Manufacturing

Polycarbonate has good impact resistance, heat distortion resistance, good weather resistance and high hardness, so it is suitable for the production of car and light truck parts, such as lighting systems, instrument panels, heating plates, defrosters and polycarbonate. Bumper made of ester alloy.

3. Medical instruments

Such as the production of syringes, surgical masks, disposable dental appliances, etc.

4. Empty day

With the rapid development of space and technology, the requirements for various components in aircraft and celestial bodies are constantly increasing, and the use of PCs in this field is also increasing.

5. Packaging field

Polycarbonate products have the advantages of light weight, good impact resistance and transparency, and are not deformed and kept transparent when washed with hot water and corrosive solution, in some fields. The PC bottle has completely replaced the glass bottle.

6. Electronic appliances

Polycarbonate resin is mainly used in the production of various food processing machinery, power tool housings, body, brackets, refrigerator freezer drawers and vacuum cleaner parts. Moreover, polycarbonate materials have also shown great use value for computers with high precision parts, video recorders and important components in color TV sets.

7. Pptical lens

Optical grade PC board can be used for cameras, microscopes, telescopes and optical test instruments, film projector lenses, copier lenses, infrared autofocus projector lenses, laser beam printer lenses, and various prisms, polygon mirrors, etc. PC boards The optical lens can also be used for lens materials for children's glasses, sunglasses and safety glasses and adult glasses.

8. Ptical illumination

It is used in the manufacture of large lampshades, protective glass, left and right eyepieces of optical instruments, etc. It can also be widely used for transparent materials on airplanes.

9. Electronic appliances

The PC board is an excellent insulating material for manufacturing insulated connectors, coil frames, sockets, bushings, telephone housings and parts, and battery cases for miner's lamps. CD, telephone, electronic computer, video recorder, telephone switch, signal relay and other communication equipment.

Specification:

|

Item name |

PC ( Polycarbonate) sheet |

|

Type: |

extruded |

|

Size: |

1000*2000mm |

|

Thickness: |

15---200mm |

|

Density: |

1.2 g/cm³ |

|

Color: |

Translucent |

|

Brand name: |

AHD |

|

Material: |

100% virgin material |

|

Sample: |

FREE |

|

Acid resistance: |

YES |

|

Food Contact |

YES |

Physical Datasheet:

|

Item |

PC sheet |

|

Color: |

clear |

|

Proportion: |

1.2g/cm³ |

|

Heat resistance (continuous): |

125℃ |

|

Heat resistance (short-term): |

135℃ |

|

Glass transition temperature: |

150℃ |

|

Linear thermal expansion coefficient (average 23~100℃): |

65×10-6 m/(m.k) |

|

Average 23--150℃ |

65×10-6 m/(m.k) |

|

Flammability(UI94): |

HB |

|

Tensile modulus of elasticity: |

2400MPa |

|

Dipping into water at 23℃ for 24h |

13% |

|

Dipping into water at 23℃ |

0.35% |

|

Bending tensile stress/ Tensile stress off shock |

70/- Mpa |

|

Breaking tensile strain |

˃50% |

|

Compressive stress of normal strain-1%/2%: |

18/35 MPa |

|

Pendulum gap impact test |

9 KJ/m2 |

|

Friction coefficient: |

0.55 |

|

Rockwell hardness: |

M75 |

|

Dielectric strength: |

28 kv/mm |

|

Volume resistance: |

10 15Ω×cm |

|

Surface resistance: |

10 15Ω |

|

Relative dielectric constant-100HZ/1MHz: |

3/3 |

|

Critical tracking index(CTI) |

600 |

|

Bonding capacity: |

+ |

|

Food contact: |

+ |

|

Acid resistance: |

+ |

|

Alkali resistance |

- |

|

Carbonated water resistance: |

0 |

|

Aromatic compound resistance: |

- |

|

Ketone resistance: |

- |

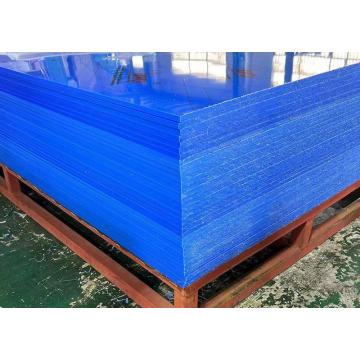

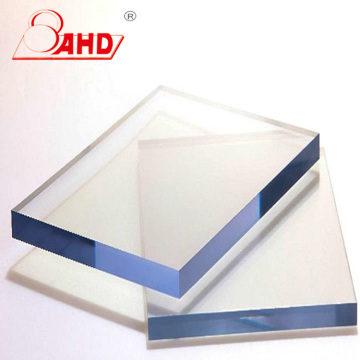

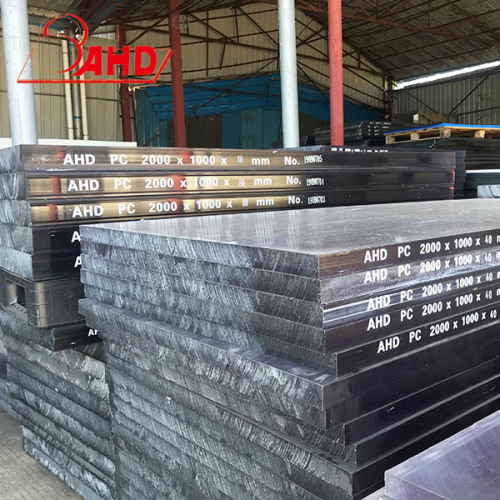

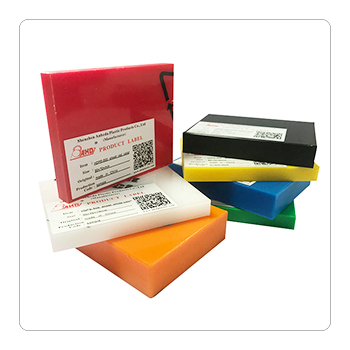

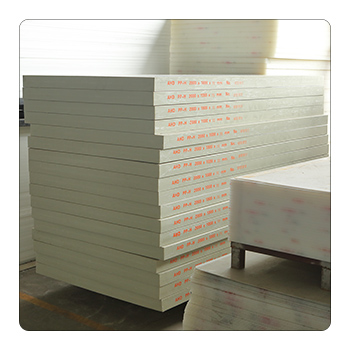

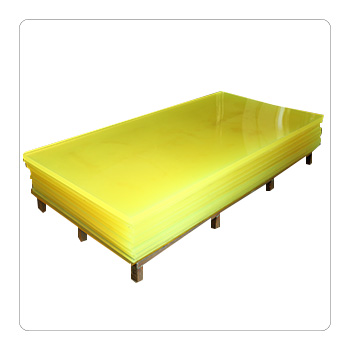

PC Sheet Photo:

Other Products:

|

|

|

|

Hdpe Plastic Sheets |

PA6 Sheet |

POM Rod |

|

|

|

|

Polypropylene Sheet |

POM Sheet |

PU Sheet |

Certification:

Production Line:

Exhibition:

Anheda group is invited to participate in domestic and international trade exhibitions every year as the most representative exhibitor,has widely attracted the attention of customers from all over the world.It making anheda group play more loudly, spread farther and have wider influence.

FAQ:

Q1: Are you a manufacturer?

A1: Yes, AHD the the semi-finished engineering plastic products manufacturer in Shenzhen China since 1994s. Our main goods include [POM, HDPE, PP, PU, PA6, ABS, POM+GF, ESD POM, PA6+GF" sheet & rod.

Q2:How do I know your quality?

A2: Free sample will be able to verify our quality.

Q3: What`s payment?

A3: T/T,L/C,Western Union etc. About the payment details please feel free to contact free to contact us.Thank you!

Q4:Can you supply sample?

A4:Yes,we can supply you free small samples,but air cost will be paid by customers.

Q5:How many days will the samples be finished?And how about the mass production?

A5: Generally the samples will be sent immediately by the air express in 1--3 days, the leading time mass production is depended on the stock status and sizes

Related Keywords